Can Concrete and Steel Ever be Carbon Neutral?

|

Concrete and steel are fundamental construction materials. Around 15,000 million tonnes of concrete, and 1,600 million tonnes of steel are produced annually, each responsible for approximately 4% of global CO2 emissions. The question is, if the concrete and steel industries switched to renewable energy sources for heat and electricity could we achieve a zero-carbon supply of these core construction materials?

[edit] Concrete

The fundamental components of concrete are cement, aggregates and water. Cement production is the most carbon-intensive element of concrete manufacture.

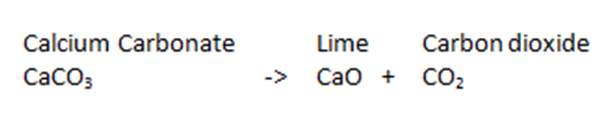

Cement is composed of approximately 60% lime and lime is made from the decarbonisation of calcium carbonate (limestone).

For those of us who paid attention in chemistry class, we can deduce that for every tonne of cement produced the decarbonisation of limestone to create the lime produces around 0.47 tonnes of CO2. Given that the average carbon footprint of cement is around 0.913 tonnes CO2e/tonne, over 50% of the carbon footprint is due to the chemical reaction taking place rather than the energy required to manufacture the cement.

For those of us who paid attention in chemistry class, we can deduce that for every tonne of cement produced the decarbonisation of limestone to create the lime produces around 0.47 tonnes of CO2. Given that the average carbon footprint of cement is around 0.913 tonnes CO2e/tonne, over 50% of the carbon footprint is due to the chemical reaction taking place rather than the energy required to manufacture the cement.

As the chemistry will never change, and suggestions that carbon-capture and storage would substantially increase cement costs making it an unviable solution for developing countries, we need other solutions to this carbon conundrum.

The United Nations Environment Programme (UNEP) has funded research into alternatives to calcium carbonate. It seems that the only alternative to calcium carbonate, in terms of chemical properties and global availability is Al2 O3, otherwise known as bauxite, the global supply of which is currently required to produce aluminium. There are other alternatives but none are available in the volume required to meet global cement demands.

Cement substitutions are viable options for reducing the carbon intensity of concrete. Pulverised fuel ash (PFA) and ground granulated blast furnace slag (GGBS) - by-products from coal-fired power stations and steel-making respectively - are two such widely used substitutes. However, they can only partially substitute cement and global supply is only about 25% of global cement demand. As the world moves away from coal-based energy production and invests in modern electric-arc furnace (EAF) technology for steel production, the global supply of PFA and GGBS will decrease even further.

There is on-going research into other substitutions but it is important to note that they are not complete replacements for cement, so it seems unlikely that concrete will ever fully eliminate the need for cement, and thus never achieve complete carbon neutrality.

[edit] Steel

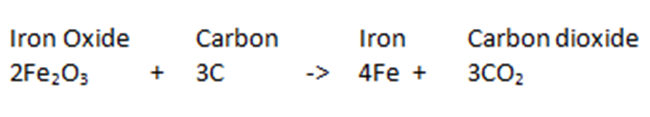

The prevailing process in steel production is the heating of iron ore (iron oxide) with carbon to produce iron, with carbon dioxide released as a by-product. Steel is simply an alloy of iron and carbon.

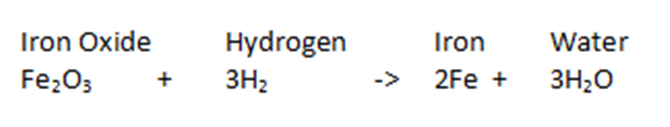

An interesting alternative could be to reduce iron oxide with hydrogen instead of carbon, releasing only water in the process: again, the chemists among us will deduce that approximately 0.6 tonnes of CO2 is released in this chemical reaction for every tonne of iron produced. This accounts for approximately 20% of the total embodied carbon of primary steel production, which is 2.89 tonnesCO2e/tonne.

It is well-known that recycled steel has a much lower carbon intensity than primary steel, 0.47 tonnesCO2e/tonne, the majority of which is associated with the energy required to fuel the process rather than the chemical reactions occurring. However, as with cement there are limitations to a simple substitution strategy. The majority of the world has yet to reach steel equilibrium, in which the production of scrap steel is equivalent to the demand for new steel, though some European countries, including the UK, are reaching this equilibrium. However, there is another hurdle to cross: around 70% of the world’s steel is produced by basic oxygen furnaces (BOF) and BOFs can only take about 20% recycled scrap. The more efficient recycling route for scrap is via electric arc furnaces, so even if steel equilibrium could be reached on a global scale there would need to be massive investment to replace existing BOFs with EAFs.

There is ongoing research in this area, but of course we need energy to produce the hydrogen.

[edit] Conclusions

There are major challenges to achieving an 80% reduction in global carbon emissions. Steel and concrete alone account for over 8% of carbon emissions globally. Disruptive innovation across all levels of the supply chain will be required to significantly reduce the impact of these core construction materials.

Consulting engineers across the globe must start by:

- Designing more efficiently on every project: Research by Cambridge University suggests that massive carbon savings can be made by designing buildings for lowest material use rather than lowest cost, and

- Engineers can also ensure that cement substitutes are specified as part of every concrete mix design.

Industry needs to focus more on the disruptive process technologies being developed in the research institutions across the globe, rather than expensive carbon capture and storage technology.

So, while we may never be carbon neutral as an industry, we can certainly go a long way to delivering our share of the 80% carbon reduction required by 2050.

Featured articles and news

Call for greater recognition of professional standards

Chartered bodies representing more than 1.5 million individuals have written to the UK Government.

Cutting carbon, cost and risk in estate management

Lessons from Cardiff Met’s “Halve the Half” initiative.

Inspiring the next generation to fulfil an electrified future

Technical Manager at ECA on the importance of engagement between industry and education.

Repairing historic stone and slate roofs

The need for a code of practice and technical advice note.

Environmental compliance; a checklist for 2026

Legislative changes, policy shifts, phased rollouts, and compliance updates to be aware of.

UKCW London to tackle sector’s most pressing issues

AI and skills development, ecology and the environment, policy and planning and more.

Managing building safety risks

Across an existing residential portfolio; a client's perspective.

ECA support for Gate Safe’s Safe School Gates Campaign.

Core construction skills explained

Preparing for a career in construction.

Retrofitting for resilience with the Leicester Resilience Hub

Community-serving facilities, enhanced as support and essential services for climate-related disruptions.

Some of the articles relating to water, here to browse. Any missing?

Recognisable Gothic characters, designed to dramatically spout water away from buildings.

A case study and a warning to would-be developers

Creating four dwellings... after half a century of doing this job, why, oh why, is it so difficult?

Reform of the fire engineering profession

Fire Engineers Advisory Panel: Authoritative Statement, reactions and next steps.

Restoration and renewal of the Palace of Westminster

A complex project of cultural significance from full decant to EMI, opportunities and a potential a way forward.

Apprenticeships and the responsibility we share

Perspectives from the CIOB President as National Apprentice Week comes to a close.

Comments

Thanks for the useful summary.

I agree with your point that cement manufacture fundamentally involves carbon production, but add the clarification that this applies specifically to Portland cement. There is a growing body of research and industry backing towards alternative cements such as geopolymer cements which remove this inherent chemical reaction.

I'd suggest interested readers start with the excellent "Rethinking Cement" paper released by Beyond Zero Emissions on this topic.