Business focused maintenance

Contents |

[edit] Why use Business Focused Maintenance?

Why do we do maintenance? Is it to keep our assets in optimum working condition? Do we do it to make the equipment last longer? Perhaps the main goal is to prevent failures? If it is for any of these reasons you may find that you are working to an outdated ethos…

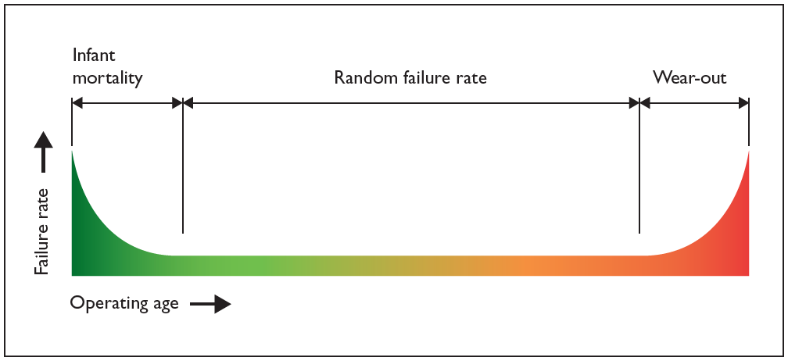

BSRIA has recognised and employ a more pragmatic approach for today’s business needs. Business Focused Maintenance (BFM) recognises that building services’ equipment is installed to provide a service, thereby allowing a business function to be maintained. It analyses the business needs and consequences of failure first and foremost. This ensures that business function is maintained with the minimum of intrusive maintenance to minimise maintenance induced failure, otherwise it is traditionally assumed that the built environment’s asset failure follows the bathtub curve.

There are standard specifications for maintenance within the building services industry that have been updated over the years such as SFG20. This is used by many organisations to enable them to tender for outsourced maintenance on a like-for-like basis. The main drawback of this approach is that the maintenance delivered will be generic across the site. This can increase costs and/or reduce the availability of human resources. Couple this with the often-quoted statistic that “70% of failures are due to ineffective maintenance” and it begs the questions to be asked over purely time-based Planned Preventative Maintenance (PPM) frequencies.

BFM recognises that the need for maintenance generally arises from business needs such as:

- Complying with legislation

- Minimising health and safety risks

- Minimising business risks

- Managing business continuity

- Responding to business and customer requirements

- Adding value as part of the business process

- Reducing overall business costs

- Maximising whole life cost

- Increasing asset / system availability

- Increasing operational up time

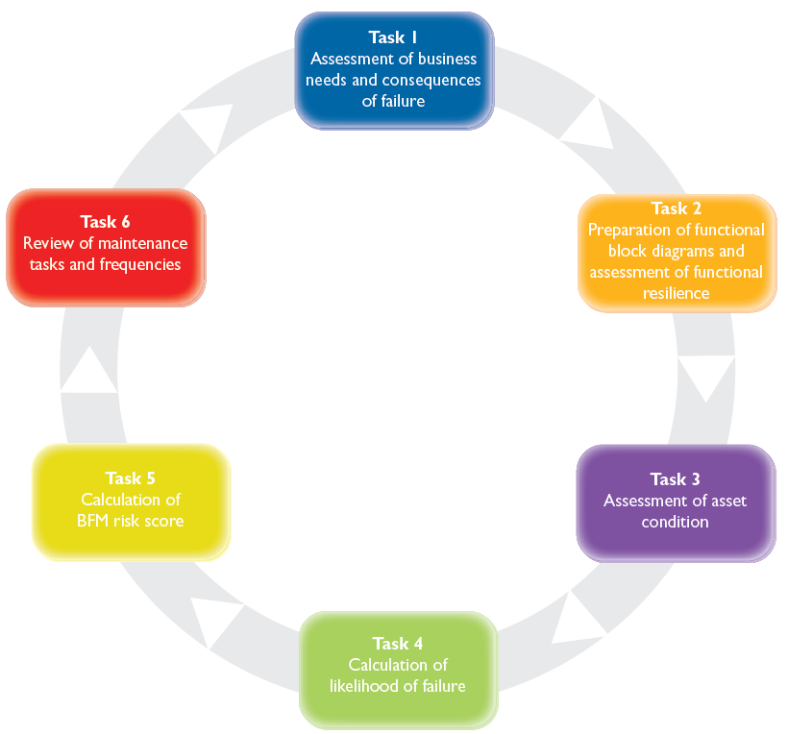

Users of BFM – first published as a BSRIA Guide in 2004 – have demonstrated increased system availability and greatly reduced costs. There is a structured, six-step process to follow where the client and BSRIA work collaboratively to:

[edit] 1 Assess business needs and consequences of asset failure

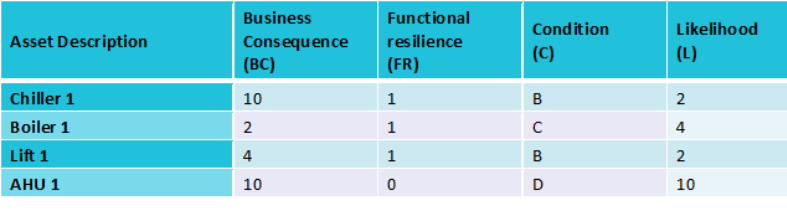

The goals of the business and the needs of the end users are assessed to ascertain which assets are crucial, and therefore the impact on the business of assets failing. The structure of BFM allows for this task to be done as objectively as possible and logged on a numeric scale of 1-10. 1 is a low consequence and 10 is a high impact on business continuity.

[edit] 2 Document functional block diagrams and assess functional resilience

Review the systems and assess their ability to continue to meet the needs of the business when a failure occurs.

[edit] 3 Assess asset condition

A full condition survey as per BG 35/2012 taking into account all relevant influences on an assets condition, to provide a remaining life expectancy.

[edit] 4 Calculate likelihood of failure

Converts the alpha-numeric score from tasks 3 and 2 to a 1-10 score via conversion table 6 in the BFM guide BG 53/2016.

[edit] 5 Calculate BFM score

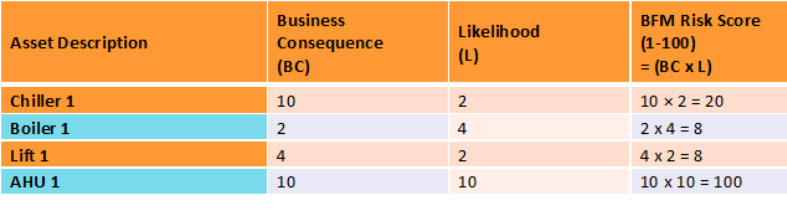

Combine the score from task 1 (BC) with the number calculated in task 4 (L) to give a BFM risk score on a scale of 1-100.

[edit] 6 Review of PPM tasks and frequency

Apply scores to the agreed level of risk set by the organisation. From this a revised maintenance schedule can be drawn up. BG 53/2016 suggests the following:

- 1-9 Discretionary maintenance for non-critical assets

- 10-40 Legal compliance and sector specific requirements

- 41-100 Maintenance to provide the greatest level of confidence in asset reliability, performance and availability.

Whilst every job is different, an indicative timeline can show you that BFM can very quickly make it’s impact on businesses.

The business-focused maintenance methodology challenges the planned preventative maintenance frequency of building services plant. The assessment methodology takes into account plant history (age, condition, failure history, plant loading, and maintenance history), the number of standby plant items (redundancy), and the level of resources available.

Many of the intrusive maintenance tasks can be replaced by Condition Monitoring (CM) which in turn leads to Condition Based Maintenance (CBM). The actual practice of CM is far quicker in terms of man hours than time-based PPMs and often involves zero down time to the asset and therefore no impact to the business. In addition to the usual array of gauges on an asset or its BMS sensor display that can be used to monitor plant performance, common CM methods include thermal imaging, vibration monitoring, acoustic emission monitoring and lubricant analysis.

Regular use of these methods at appropriate intervals can be far more cost effective than regular time-based generic intervals, whereas for non-critical plant, the most cost-effective maintenance methodology may be to run-to-failure. By applying the BFM methodology, you can be confident that you have selected the most appropriate maintenance technique for the services in your building.

This article originally appeared as ‘Why use Business Focused Maintenance?’ on the BSRIA blog, published on 3 March 2020. It was written by Nick Blake – Principal FM Consultant at BSRIA. You can download Business Focused Maintenance (BG53/2016) here.

--BSRIA

[edit] Related articles on Designing Buildings Wiki

- BSRIA articles on Designing Buildings Wiki.

- BSRIA.

- Building Services Analytics - BG 75 2018

- Business-Focused Maintenance BG53 2016.

- Carbon neutral contract.

- Design for maintenance.

- In-house or outsource maintenance.

- Maintenance and operational strategy.

- Maintenance.

- Maximising maintenance budgets after lockdown.

- O&M manual.

- Operation, maintenance and training (OMT).

- Planned preventive maintenance.

- Predictive maintenance.

- Proactive maintenance.

- Reliability centred maintenance.

- Repair and maintenance contract.

- Scheduled maintenance.

- Soft landings and business-focused maintenance.

- Unplanned maintenance.

Featured articles and news

A case study and a warning to would-be developers

Creating four dwellings... after half a century of doing this job, why, oh why, is it so difficult?

Reform of the fire engineering profession

Fire Engineers Advisory Panel: Authoritative Statement, reactions and next steps.

Restoration and renewal of the Palace of Westminster

A complex project of cultural significance from full decant to EMI, opportunities and a potential a way forward.

Apprenticeships and the responsibility we share

Perspectives from the CIOB President as National Apprentice Week comes to a close.

The first line of defence against rain, wind and snow.

Building Safety recap January, 2026

What we missed at the end of last year, and at the start of this...

National Apprenticeship Week 2026, 9-15 Feb

Shining a light on the positive impacts for businesses, their apprentices and the wider economy alike.

Applications and benefits of acoustic flooring

From commercial to retail.

From solid to sprung and ribbed to raised.

Strengthening industry collaboration in Hong Kong

Hong Kong Institute of Construction and The Chartered Institute of Building sign Memorandum of Understanding.

A detailed description from the experts at Cornish Lime.

IHBC planning for growth with corporate plan development

Grow with the Institute by volunteering and CP25 consultation.

Connecting ambition and action for designers and specifiers.

Electrical skills gap deepens as apprenticeship starts fall despite surging demand says ECA.

Built environment bodies deepen joint action on EDI

B.E.Inclusive initiative agree next phase of joint equity, diversity and inclusion (EDI) action plan.

Recognising culture as key to sustainable economic growth

Creative UK Provocation paper: Culture as Growth Infrastructure.