Escalator

Contents |

[edit] Introduction

Escalators are mechanical devices used for transporting people vertically between different levels of buildings. Typically, they take the form of a moving staircase, consisting of a 'chain' of single-piece aluminium or stainless steel steps guided by a system of tracks in a continuous loop.

Escalators are commonly used in buildings where the movement of a large number of people is required, such as shopping centres, airports, transit systems, exhibition halls, hotels, arenas, public buildings, and so on.

They occupy the same physical space as a staircase, generally have no waiting time (other than during periods of congestion), allow a greater flow of people, and can be more practical than lifts. It is also possible for people to walk up or down escalators, if they are in a hurry, or if they break down.

A variation of the escalator is the moving walkway, which transports people horizontally.

[edit] History

The first escalator was patented by two Americans, Leamon Souder and Nathan Ames, in the mid-19th century. However, their patented designs were never manufactured.

It wasn’t until the early-20th century that a working prototype designed by Charles Seeburger and Jesse Reno was produced. Their working model gained a lot of attention and was first installed in New York City’s department stores. In 1910, Seeburger and Reno sold their invention to the Otis Elevator Company.

[edit] Speed

The speed of escalators is constant and is generally around 0.3-0.6 m (1-2 ft) per second. This translates to around 27-55 m (90-180 ft) per minute. An escalator moving an average of 44 m (145 ft) per minute can transport over 10,000 people per hour, which is a considerably higher capacity than a standard lift system.

[edit] Configurations

There are three basic configurations that are used for most common escalator systems:

- Parallel: Escalators positioned side-by-side, moving in opposite directions.

- Criss-cross: Escalators moving in one direction are ‘stacked’, minimising space requirements.

- Multiple parallel: A bank of two or more escalators, with differing directions.

[edit] Design considerations

There a number of factors that affect the design of escalator systems, including:

- The vertical and horizontal distance to be spanned.

- The location.

- Other building infrastructure.

- Traffic patterns.

- Carrying capacity.

- Safety considerations.

- Aesthetic preferences.

[edit] Escalator components

The following components make up an escalator system:

[edit] Landing platforms

These contain the curved sections of the tracks, in addition to the gears and motors. The floor plate provides space for users to stand before stepping onto the moving steps. The comb plate has a series of cleats (like the teeth of a comb), that mesh with matching cleats on the edges of the steps and minimise the gap between the stair and the landing.

[edit] Truss

The structure that bridges the lower and upper landings, and carries the straight track sections. Steel or concrete supports connect the ends of the truss to the top and bottom landing platforms.

[edit] Balustrade

This is the structure supporting the handrail of the escalator and can be made of metal, sandwich panels or glass.

[edit] Handrail

The handrail moves courtesy of a chain connected to the main drive gear by a series of pulleys. It is generally made from a blend of synthetic polymers and rubber, and is designed to be very durable.

[edit] Tracks

The step-wheel track for the front wheels of the steps, and the trailer-wheel track for the back wheels of the steps, cause the steps to form a staircase as they move from under the comb plate.

[edit] Steps

These are typically solid and made of die-cast aluminium or steel. They are cleated with comb-like protrusions that mesh with the comb plates. The steps are linked by a continuous metal chain that forms a closed loop.

The steps, connected in series, always step level as they move. The steps create a flat platform at both the top and the bottom of the escalator by collapsing on each other. This works by way of the two sets of wheels on each step. The upper set of wheels are connected to the rotating chains, pulled by the gears at the top of the escalator. The lower set of wheels follow behind and just glide along on their track.

[edit] Motor

Escalators are driven by a motor and chain system inside the truss. At its core are a pair of chains looped around two pairs of gears. The gears at the top of the escalator are turned by an electric motor, which in turn rotates the chain loops. The electric motor also powers the moving handrail which is looped around a series of wheels and is configured so that it moves at a similar speed to the steps.

[edit] Related articles on Designing Buildings Wiki

Featured articles and news

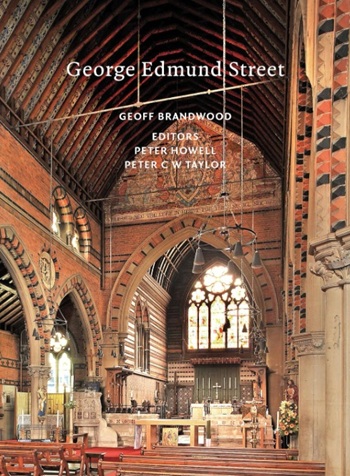

One of the most impressive Victorian architects. Book review.

Common Assessment Standard now with building safety

New CAS update now includes mandatory building safety questions.

RTPI leader to become new CIOB Chief Executive Officer

Dr Victoria Hills MRTPI, FICE to take over after Caroline Gumble’s departure.

Social and affordable housing, a long term plan for delivery

The “Delivering a Decade of Renewal for Social and Affordable Housing” strategy sets out future path.

A change to adoptive architecture

Effects of global weather warming on architectural detailing, material choice and human interaction.

The proposed publicly owned and backed subsidiary of Homes England, to facilitate new homes.

How big is the problem and what can we do to mitigate the effects?

Overheating guidance and tools for building designers

A number of cool guides to help with the heat.

The UK's Modern Industrial Strategy: A 10 year plan

Previous consultation criticism, current key elements and general support with some persisting reservations.

Building Safety Regulator reforms

New roles, new staff and a new fast track service pave the way for a single construction regulator.

Architectural Technologist CPDs and Communications

CIAT CPD… and how you can do it!

Cooling centres and cool spaces

Managing extreme heat in cities by directing the public to places for heat stress relief and water sources.

Winter gardens: A brief history and warm variations

Extending the season with glass in different forms and terms.

Restoring Great Yarmouth's Winter Gardens

Transforming one of the least sustainable constructions imaginable.

Construction Skills Mission Board launch sector drive

Newly formed government and industry collaboration set strategy for recruiting an additional 100,000 construction workers a year.

New Architects Code comes into effect in September 2025

ARB Architects Code of Conduct and Practice available with ongoing consultation regarding guidance.

Welsh Skills Body (Medr) launches ambitious plan

The new skills body brings together funding and regulation of tertiary education and research for the devolved nation.

Paul Gandy FCIOB announced as next CIOB President

Former Tilbury Douglas CEO takes helm.