Pile cap

Foundations provide support for structures, transferring their load to layers of soil or rock that have sufficient bearing capacity and suitable settlement characteristics to support them.

Very broadly, foundations can be categorised as shallow foundations or deep foundations.

- Shallow foundations are typically used where the loads imposed by a structure are low relative to the bearing capacity of the surface soils.

- Deep foundations are necessary where the bearing capacity of the surface soils is not adequate and so loads need to be transferred to deeper layers with higher bearing capacity.

Pile foundations are deep foundations. They are formed by long, slender, columnar elements typically made from steel or reinforced concrete, or sometimes timber. A foundation is described as 'piled' when its depth is more than three times its breadth.

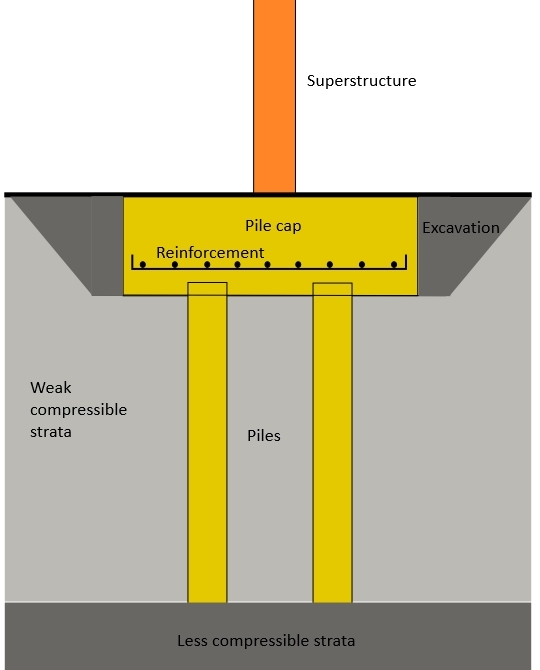

Pile foundations are principally used to transfer the loads from superstructures, through weak, compressible strata or water onto stronger, more compact, less compressible and stiffer soil or rock at depth, increasing the effective size of a foundation and resisting horizontal loads. They are typically used for large structures, and in situations where soil is not suitable to prevent excessive settlement.

Piles can be used individually, or they can be grouped together and linked by a reinforced concrete cap. Pile caps create a stable foundation and offer a larger area for the distribution of the building load onto the piles. They act in a similar way to piled raft foundations, where a concrete slab rests on soil which may be susceptible to movement, above a group of piles.

|

The number of piles in the group, and the spacing between them, determines the shape and plan dimensions of the pile cap. The shapes of pile caps are typically either:

It is usual for a pile cap to be of a greater depth than a comparable pad footing as it is typically subject to higher bending moments and shear forces. The pile cap achieves greater rigidity from the increased depth, which enables it to evenly spread the load to all piles in the group. The factors that determine the depth of the pile cap include:

- The shear capacity of the pile cap.

- Shrinkage and swelling of the ground (particularly in clay soils).

- Pile anchorage.

- The ground’s watertable.

- The possibility of frost attack.

As it is very difficult to bore or drive piles exactly vertically, the pile cap should be able to accommodate some deviation in the final position of the pile heads. The pile cap should overhang the outer piles, typically by a distance of 100-150 mm on all sides, depending on the size of the piles.

Pile caps are constructed by excavating an area around the group of piles to enable formwork to be inserted. The pile tops may be trimmed to ensure they are at the same height. A reinforcement cage is then built and positioned in the formwork cast box and fastened to the piles. The concrete is then poured and left to cure, after which the formwork is removed.

NB High Speed Rail (Crewe – Manchester) Environmental Statement, Glossary, abbreviations and references, published by the Department for Transport in 2022, defines a pile cap as: ‘A concrete structure used to link a number of discrete pile elements into a single arrangement to support significant loads that the pile elements are not capable of supporting individually.’

[edit] Related articles on Designing Buildings

Featured articles and news

A case study and a warning to would-be developers

Creating four dwellings for people to come home to... after half a century of doing this job, why, oh why, is it so difficult?

Reform of the fire engineering profession

Fire Engineers Advisory Panel: Authoritative Statement, reactions and next steps.

Restoration and renewal of the Palace of Westminster

A complex project of cultural significance from full decant to EMI, opportunities and a potential a way forward.

Apprenticeships and the responsibility we share

Perspectives from the CIOB President as National Apprentice Week comes to a close.

The first line of defence against rain, wind and snow.

Building Safety recap January, 2026

What we missed at the end of last year, and at the start of this...

National Apprenticeship Week 2026, 9-15 Feb

Shining a light on the positive impacts for businesses, their apprentices and the wider economy alike.

Applications and benefits of acoustic flooring

From commercial to retail.

From solid to sprung and ribbed to raised.

Strengthening industry collaboration in Hong Kong

Hong Kong Institute of Construction and The Chartered Institute of Building sign Memorandum of Understanding.

A detailed description from the experts at Cornish Lime.

IHBC planning for growth with corporate plan development

Grow with the Institute by volunteering and CP25 consultation.

Connecting ambition and action for designers and specifiers.

Electrical skills gap deepens as apprenticeship starts fall despite surging demand says ECA.

Built environment bodies deepen joint action on EDI

B.E.Inclusive initiative agree next phase of joint equity, diversity and inclusion (EDI) action plan.

Recognising culture as key to sustainable economic growth

Creative UK Provocation paper: Culture as Growth Infrastructure.

Futurebuild and UK Construction Week London Unite

Creating the UK’s Built Environment Super Event and over 25 other key partnerships.

Welsh and Scottish 2026 elections

Manifestos for the built environment for upcoming same May day elections.

Advancing BIM education with a competency framework

“We don’t need people who can just draw in 3D. We need people who can think in data.”

Comments

[edit] To make a comment about this article, click 'Add a comment' above. Separate your comments from any existing comments by inserting a horizontal line.

Can anyone tell me, if tie beams are connected to pile caps how much will be the %of total load transfered on piles? 100% or 50%?

Thanks