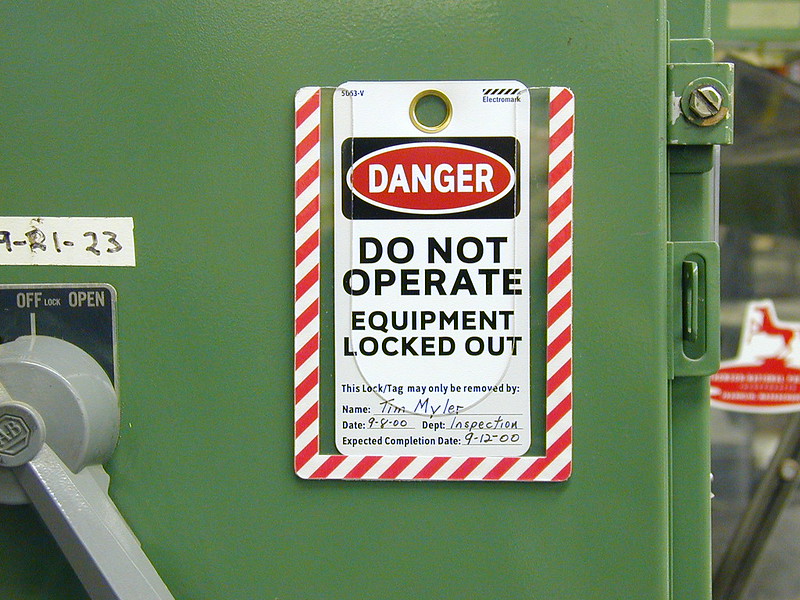

Lock out tag out LOTO

Photo credit: SmartSign from MySafetySign.com, Flickr, source: https://flic.kr/p/gE26vy.

Contents |

[edit] Introduction

Lock out tag out (also referred to as lockout/tagout or LOTO) is a safety procedure that protects workers from using machinery that could be dangerous if the power source that operates the equipment is not shut off properly. This practice is also used when machinery needs to be disconnected in order to carry out scheduled maintenance or repair work.

Lock out tag out prevents the machine from being inadvertently restarted while it is in a hazardous state. It also adds a layer of protection for workers who may come into contact with the machine while it is in an unsafe condition.

LOTO is often used when construction workers, electricians, machine operators or other labourers are doing jobs that involve - or are located in close proximity to - equipment that can be hazardous. Failure to control the power supply can result in electrocution, burns, lacerations, amputations and other serious injuries. For example, if LOTO is not used a jammed piece of equipment can suddenly restart, crushing the worker who is trying to clear the jam.

[edit] UK practices

Although this practice is not directly part of UK health and safety regulations, it is recognised as a best practice. Instead of lock out tag out, the UK follows the guidance such as BS 7671, Requirements for Electrical Installations. IET Wiring Regulations. This regulation covers required standards for wiring and electrical installations as well as providing guidance for the proper isolation of electrical equipment.

The operation and maintenance of manufacturing and construction machinery is covered under the Provision and Use of Work Equipment Regulations 1998 (1999 in Northern Ireland) (PUWER). PUWER refers to lock out tag out safety devices, but it does not include guidance as a specific part of the regulation. Instead, PUWER makes a general recommendation akin to lock out tag out practices more closely aligned with those set forward by the Occupational Safety and Health Administration (OSHA) of the United States.

[edit] OSHA practices

The OSHA standard for lock out tag out has been adopted by many international organisations. Standard 1910.147 covers the control of hazardous energy.

According to the OSHA standard, there are three key points about the specific lock out tag out devices:

- They must be identifiable.

- They can only be used for controlling power supply.

- They must be durable, standardised and substantial.

[edit] EU practices

EU 1989/655 guidelines for lock out tag out practices are OSHA based. There is also a specific safety procedure that should be followed when electric equipment is being serviced. This Standard, EN 50110-1, recommends the following five steps:

- Disconnect the equipment completely.

- Secure the machinery so it cannot be reconnected unintentionally.

- Confirm the installation is not operating.

- Perform earthing and short circuiting procedures.

- Protect any live equipment that may be located in close proximity to the equipment being serviced.

[edit] Creating LOTO policy

Lock out tag out policy sets specific safety goals, provides instructions about how to undertake LOTO (by isolation) and explains the benefits and consequences of the policy.

Isolating equipment can include the following procedures:

- Announcing shut off of the equipment.

- Identifying the source(s) of energy.

- Isolating source(s) of energy.

- Locking and tagging sources of energy.

- Proving that the isolation has been successful

Sometimes testing is added to this procedure (referred to as lock tag try or LTT). This takes place when there is an attempt to turn the equipment back on once the isolation step is complete.

It is important to coordinate all lock out tag out plans in advance and specify the duration of the work along with the equipment that will be isolated. It may also be necessary to mark work zones where the isolation will take place to minimise the risk of slip fall occurrences and to prevent access in hazardous areas.

[edit] Related articles on Designing Buildings

- Amendment 3 BS 7671 Requirements for Electrical Installations IET Wiring Regulations.

- Construction health risks.

- Electrical safety.

- Forklift truck.

- Health and safety.

- Health and Safety Executive.

- Health and safety policy.

- Occupational Safety and Health Administration OSHA.

- Safe isolation for low voltage.

[edit] External resources

- BSI, BS 7671:2018+A1:2020 Requirements for Electrical Installations. IET Wiring Regulations

- BS EN 50110-1:2013 Operation of electrical installations. General requirements.

- Legislation.gov.uk, Council Directive of 30 November 1989 concerning the minimum safety and health requirements for the use of work equipment by workers at work (second individual Directive within the meaning of Article 16 (1) of Directive 89/391/EEC) (89/655/EEC) (repealed).

- Legislation.gov.uk, The Provision and Use of Work Equipment Regulations 1998.

- OSHA, Control of Hazardous Energy (Lockout/Tagout).

- OSHA, Standard 1910.147: The control of hazardous energy (lockout/tagout).

Featured articles and news

A case study and a warning to would-be developers

Creating four dwellings... after half a century of doing this job, why, oh why, is it so difficult?

Reform of the fire engineering profession

Fire Engineers Advisory Panel: Authoritative Statement, reactions and next steps.

Restoration and renewal of the Palace of Westminster

A complex project of cultural significance from full decant to EMI, opportunities and a potential a way forward.

Apprenticeships and the responsibility we share

Perspectives from the CIOB President as National Apprentice Week comes to a close.

The first line of defence against rain, wind and snow.

Building Safety recap January, 2026

What we missed at the end of last year, and at the start of this...

National Apprenticeship Week 2026, 9-15 Feb

Shining a light on the positive impacts for businesses, their apprentices and the wider economy alike.

Applications and benefits of acoustic flooring

From commercial to retail.

From solid to sprung and ribbed to raised.

Strengthening industry collaboration in Hong Kong

Hong Kong Institute of Construction and The Chartered Institute of Building sign Memorandum of Understanding.

A detailed description from the experts at Cornish Lime.

IHBC planning for growth with corporate plan development

Grow with the Institute by volunteering and CP25 consultation.

Connecting ambition and action for designers and specifiers.

Electrical skills gap deepens as apprenticeship starts fall despite surging demand says ECA.

Built environment bodies deepen joint action on EDI

B.E.Inclusive initiative agree next phase of joint equity, diversity and inclusion (EDI) action plan.

Recognising culture as key to sustainable economic growth

Creative UK Provocation paper: Culture as Growth Infrastructure.