Vacuum Insulated Glazing VIG

Vacuum glazing is similar to double glazing, but the cavity between the panes is a vacuum. The main advantage of vacuum glazing is that it not only performs well but has only a small cavity, which means the glazed units are thin and light in comparison to standard double glazed units.

This type of unit is often the favoured option for historic buildings because vacuum units can be installed as individual panes between the transom and mullions of traditional timber frame windows. The thickness of a vacuum sealed units can be a low as 6mm, which is less than half the thickness of traditional double glazed units (around 20mm) which means in some cases they can even be installed within existing or refurbished timber frames. The performance of such windows can be from around 1.0 W/M2. K down to 0.5 W/M2.K, which is lower than the 1.2 to 3.7 W/(m²K) of standard double glazed units.

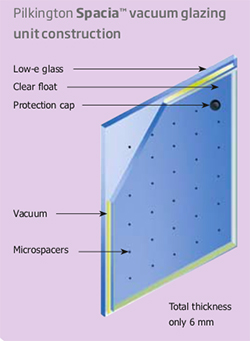

The cost of a vacuum glazed units is likely to be higher than standard double glazed units because of the precision nature of their design and manufacture. The natural effect of having a vacuum between the glazing panes is that the panes want to pull together, they are prevented from doing so through the insertion of tiny micro-spacers, less than a 1mm in diameter laid in a regular grid between the panes. These micro spacers are transparent and can often barely be seen.

The concept for vacuum glazing itself was developed as a proof of concept in the 1990's at the University of Sydney with initial commercialisation by Nippon Sheet Glass, Japan, in 1996. Pilkington glass consider their own SpaciaTM glazed unit to have been the world's first commercially available vacuum glazing, with sales starting a year later in 1997.

Pilkington Spacia™ is one example of a vacuum sealed product and available from Pilkington. It offers the thermal performance of conventional double glazing in the same thickness as a single glass pane. It balances historic preservation with modern comfort and environmental requirements, with a float glass pane on the inside and a low-emissivity glass pane on the outside, hermetically sealed. A diagram of the how a pane is made-up is given here, courtesy of the Pilkington, for further information visit the website directly by clicking the image.

[edit] Related articles on Designing Buildings

- Conservation rooflights.

- Domestic windows.

- Double glazing.

- Double glazing v triple glazing.

- Glass.

- Glazier.

- Glazing.

- Low-E glass.

- Patent glazing.

- Secondary glazing.

- Security glazing.

- Stained glass.

- Structural glass assembly.

- Suction lifter.

- Tempered glass.

- Triple glazing.

- Types of window.

- Window.

- Window frame.

Featured articles and news

UKCW London to tackle sector’s most pressing issues

AI and skills development, ecology and the environment, policy and planning and more.

Managing building safety risks

Across an existing residential portfolio; a client's perspective.

ECA support for Gate Safe’s Safe School Gates Campaign.

Core construction skills explained

Preparing for a career in construction.

Retrofitting for resilience with the Leicester Resilience Hub

Community-serving facilities, enhanced as support and essential services for climate-related disruptions.

Some of the articles relating to water, here to browse. Any missing?

Recognisable Gothic characters, designed to dramatically spout water away from buildings.

A case study and a warning to would-be developers

Creating four dwellings... after half a century of doing this job, why, oh why, is it so difficult?

Reform of the fire engineering profession

Fire Engineers Advisory Panel: Authoritative Statement, reactions and next steps.

Restoration and renewal of the Palace of Westminster

A complex project of cultural significance from full decant to EMI, opportunities and a potential a way forward.

Apprenticeships and the responsibility we share

Perspectives from the CIOB President as National Apprentice Week comes to a close.

The first line of defence against rain, wind and snow.

Building Safety recap January, 2026

What we missed at the end of last year, and at the start of this...

National Apprenticeship Week 2026, 9-15 Feb

Shining a light on the positive impacts for businesses, their apprentices and the wider economy alike.

Applications and benefits of acoustic flooring

From commercial to retail.

From solid to sprung and ribbed to raised.

Strengthening industry collaboration in Hong Kong

Hong Kong Institute of Construction and The Chartered Institute of Building sign Memorandum of Understanding.

A detailed description from the experts at Cornish Lime.