Rubber Molding in the Construction

Contents |

[edit] Applications of Rubber Molding in the Construction Industry

Rubber molding technology plays a vital role in modern construction. From enhancing structural durability to improving waterproofing and vibration control, rubber-molded products are essential across various areas of building design and infrastructure. As construction methods evolve, the demand for precision-engineered rubber components continues to grow.

[edit] What Is Rubber Molding?

Rubber molding is a manufacturing process that shapes uncured rubber into finished parts using heat and pressure. The molded rubber components are strong, flexible, and highly durable—making them ideal for construction, automotive, electrical, and industrial applications.

[edit] Key Applications of Rubber Molding in Construction

1. Vibration Isolation and Seismic Protection

In bridges, high-rise buildings, and railway systems, molded rubber bearings and isolators are used to absorb vibrations and seismic forces. These components, typically made from natural or neoprene rubber, help prevent structural damage and extend the lifespan of the infrastructure.

2. Sealing and Waterproofing

Rubber gaskets, window seals, and curtain wall seals—produced through molding—are essential in preventing air and water leaks. Their excellent weather resistance and elasticity make them perfect for energy-efficient, long-lasting buildings.

3. Safety and Anti-Slip Solutions

Molded rubber floor mats, stair treads, and anti-slip strips are widely used in public spaces like hospitals, train stations, and schools. These products improve pedestrian safety with their slip resistance and durability.

4. Cable and Conduit Protection

Rubber grommets, sealing rings, and cable covers protect electrical systems in construction environments. Molded rubber ensures tight, reliable seals against dust, moisture, and mechanical impact.

[edit] Advantages of Rubber Molding

- Weather Resistance: Performs well in harsh environments including UV exposure, temperature extremes, and moisture.

- Elasticity & Flexibility: Withstands dynamic loads and continuous deformation without losing shape.

- Customization: Easily tailored to various shapes, sizes, and materials to meet specific architectural requirements.

- Eco-Friendly: Modern rubber compounds can include recyclable and low-impact materials aligned with green building standards.

[edit] Conclusion

As the construction industry moves toward smarter, safer, and more sustainable designs, rubber molding technology is becoming increasingly indispensable. Whether used for structural support, weatherproofing, or safety enhancements, molded rubber components deliver high-performance solutions for modern building challenges.

To learn more about our custom rubber molding solutions for the construction industry, please visit our official website:

Featured articles and news

Professional practical experience for Architects in training

The long process to transform the nature of education and professional practical experience in the Architecture profession following recent reports.

A people-first approach to retrofit

Moving away from the destructive paradigm of fabric-first.

International Electrician Day, 10 June 2025

Celebrating the role of electrical engineers from André-Marie Amperè, today and for the future.

New guide for clients launched at Houses of Parliament

'There has never been a more important time for clients to step up and ...ask the right questions'

The impact of recycled slate tiles

Innovation across the decades.

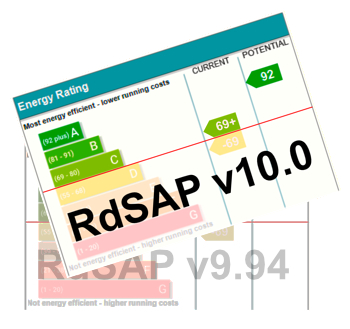

EPC changes for existing buildings

Changes and their context as the new RdSAP methodology comes into use from 15 June.

Skills England publishes Sector skills needs assessments

Priority areas relating to the built environment highlighted and described in brief.

BSRIA HVAC Market Watch - May 2025 Edition

Heat Pump Market Outlook: Policy, Performance & Refrigerant Trends for 2025–2028.

Committing to EDI in construction with CIOB

Built Environment professional bodies deepen commitment to EDI with two new signatories: CIAT and CICES.

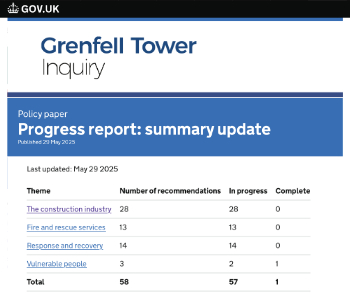

Government Grenfell progress report at a glance

Line by line recomendation overview, with links to more details.

An engaging and lively review of his professional life.

Sustainable heating for listed buildings

A problem that needs to be approached intelligently.

50th Golden anniversary ECA Edmundson apprentice award

Deadline for entries has been extended to Friday 27 June, so don't miss out!

CIAT at the London Festival of Architecture

Designing for Everyone: Breaking Barriers in Inclusive Architecture.

Mixed reactions to apprenticeship and skills reform 2025

A 'welcome shift' for some and a 'backwards step' for others.