Rivet

|

A rivet is a mechanical fastener for making a permanent join between two or more metal sheets. Riveting is the act of fastening or securing two plates with one or more rivets. The rivet comprises a shank with a plain end (or tail), and a head on the other end. The rivet has proved to be one of the most reliable and safe means of fastening, forming a permanent and structurally robust join.

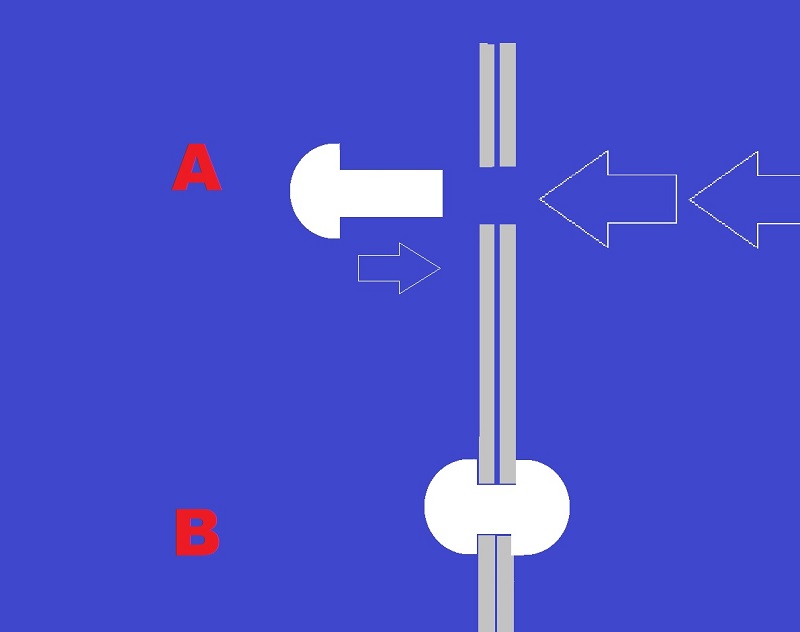

The process of riveting (or making a riveted joint) comprises making a whole in say, two metal plates, aligning the hole, then inserting the rivet through it with the plain end projecting through (‘A’ in the diagram). Hammering the projecting tail end of the rivet causes it to mushroom, expanding by around 1.5 times its original diameter, causing a head to form (‘B’) which secures the rivet and the join permanently. The final shape of the rivet is therefore similar to a dumbbell, with the original head called the factory head and the new tail end called the shop head (or buck tail). The finished rivet can support shear and tension loads.

|

Historically, riveting has been widely used in shipbuilding, bridge building and other areas where steel infrastructure was involved. It was also used in construction but nowadays rarely performed on site but more in the factory, if at all. Typically, this might have been for riveting connecting cleats to steel stanchions and beams, with the final assembly bolted together on site.

Much of the site riveting that took place in construction has been replaced by welding or bolting (bolts typically have the same strength as rivets). Aircraft manufacture makes widespread use of riveting throughout the frame and wings of the plane which can typically require hundreds of thousands of rivets.

Manual hammering is one way of securing a rivet, however in recent times other methods are used to perform the same task and include the use of a hydraulic- or pneumatic-powered air hammer, a rivet gun or a rivet crimping tool. The latter allows the riveting process to be undertaken by one person. Usually, access is required on both sides of the rivet which is why riveting has traditionally been a two-person operation. Where access to the rivet is only possible from one side, the traditional rivet is replaced by a ‘blind rivet’.

|

| Rivet gun and rivets. |

Today, structural steel in construction is mostly assembled using high-strength steel bolts. This is mainly because a bolted connection is cheaper to make than a rivet as it requires lower-skills and fewer workers to complete. Bolts can also be undone.

[edit] Related articles on Designing Buildings

Featured articles and news

A case study and a warning to would-be developers

Creating four dwellings for people to come home to... after half a century of doing this job, why, oh why, is it so difficult?

Reform of the fire engineering profession

Fire Engineers Advisory Panel: Authoritative Statement, reactions and next steps.

Restoration and renewal of the Palace of Westminster

A complex project of cultural significance from full decant to EMI, opportunities and a potential a way forward.

Apprenticeships and the responsibility we share

Perspectives from the CIOB President as National Apprentice Week comes to a close.

The first line of defence against rain, wind and snow.

Building Safety recap January, 2026

What we missed at the end of last year, and at the start of this...

National Apprenticeship Week 2026, 9-15 Feb

Shining a light on the positive impacts for businesses, their apprentices and the wider economy alike.

Applications and benefits of acoustic flooring

From commercial to retail.

From solid to sprung and ribbed to raised.

Strengthening industry collaboration in Hong Kong

Hong Kong Institute of Construction and The Chartered Institute of Building sign Memorandum of Understanding.

A detailed description from the experts at Cornish Lime.

IHBC planning for growth with corporate plan development

Grow with the Institute by volunteering and CP25 consultation.

Connecting ambition and action for designers and specifiers.

Electrical skills gap deepens as apprenticeship starts fall despite surging demand says ECA.

Built environment bodies deepen joint action on EDI

B.E.Inclusive initiative agree next phase of joint equity, diversity and inclusion (EDI) action plan.

Recognising culture as key to sustainable economic growth

Creative UK Provocation paper: Culture as Growth Infrastructure.

Futurebuild and UK Construction Week London Unite

Creating the UK’s Built Environment Super Event and over 25 other key partnerships.

Welsh and Scottish 2026 elections

Manifestos for the built environment for upcoming same May day elections.

Advancing BIM education with a competency framework

“We don’t need people who can just draw in 3D. We need people who can think in data.”