Fixed VS Mobile Asphalt Plants: Which is More Suitable for Project Contractors?

When it comes to asphalt production for road and bridge construction, contractors often face the dilemma of whether to invest in a fixed or mobile asphalt plant. Both types of plants have their advantages and disadvantages, depending on the specific needs of the project. In this article, we’ll explore the differences between fixed and mobile asphalt plants and help you decide which option is more suitable for your project.

Asphalt plants are crucial for ensuring the smooth and efficient production of high-quality asphalt, which is essential for durable and long-lasting road construction. However, the choice between a fixed and a mobile asphalt plant(planta asfaltica movil) often depends on factors like project scale, budget, location, and flexibility.

File:Mobile Asphalt Plant with 100 TPH.jpg

Contents |

[edit] Fixed Asphalt Plants: High Capacity and Long-Term Use

Fixed asphalt plants are typically large-scale operations designed for long-term, high-volume production. These plants are permanently installed at a specific location, making them ideal for large, ongoing construction projects.

[edit] Advantages of Fixed Asphalt Plants

- High Production Capacity

Fixed asphalt plants are known for their ability to produce large quantities of asphalt. These plants are designed to handle high volumes of production, making them suitable for major infrastructure projects, such as highways or large urban developments. They can run continuously for extended periods, ensuring a steady supply of asphalt throughout the project.

- Consistency and Quality

Fixed plants are often equipped with advanced technology that ensures the consistent production of high-quality asphalt. They provide greater control over the mix and are ideal for projects that require precise specifications and standards for the asphalt.

- Long-Term Investment

Fixed asphalt plants are a significant investment, but they are well-suited for contractors who expect to be working on long-term or multiple large-scale projects in the same area. If your company plans to continuously produce asphalt for different projects over several years, investing in a fixed plant could offer better value in the long run.

[edit] Disadvantages of Fixed Asphalt Plants

- Lack of Mobility

One of the biggest drawbacks of fixed plants is their immobility. They are permanent fixtures, which means they are not suitable for projects that span multiple locations or for short-term construction jobs. Transporting asphalt from a fixed plant to remote job sites can incur additional costs and logistical challenges.

- High Initial Investment

Fixed asphalt plants require a substantial initial investment, including not just the cost of the plant itself but also installation, site preparation, and maintenance. This can be a barrier for contractors working with limited budgets or those who don’t have long-term asphalt production needs.

[edit] Mobile Asphalt Plants: Flexibility and Cost Efficiency

In contrast, mobile asphalt plants are designed for flexibility and portability, offering several benefits that make them a great choice for contractors working on shorter-term or smaller-scale projects.

[edit] Advantages of Mobile Asphalt Plants

- Portability and Flexibility

The primary advantage of a mobile asphalt plant is its mobility. These plants can be easily transported from one location to another, making them ideal for projects spread across different sites. Contractors working on temporary or smaller construction jobs often find that a mobile plant provides the flexibility they need to move equipment quickly between locations.

- Lower Initial Investment

Mobile asphalt plants, including mini asphalt plants(mini planta asfáltica), tend to have a lower upfront cost compared to fixed plants. This makes them an attractive option for smaller contractors or those with limited budgets who may not need a large-scale, permanent asphalt production facility. Additionally, they require less setup and installation time, which reduces costs associated with deployment.

- Reduced Transportation Costs

For projects located far from an existing fixed plant, transporting asphalt over long distances can be both expensive and time-consuming. A mobile asphalt plant can be set up directly at the job site, eliminating the need for costly transportation of asphalt and ensuring that materials are fresh and ready for use immediately.

- Quick Setup and Dismantling

Mobile plants are designed for easy setup and dismantling. Contractors can begin producing asphalt almost immediately after the plant is delivered to the site, which can significantly reduce downtime and increase efficiency. This is especially useful in fast-paced construction environments where time is of the essence.

[edit] Disadvantages of Mobile Asphalt Plants

- Lower Production Capacity

While mobile asphalt plants are great for smaller-scale projects, they do not have the same high production capacity as fixed plants. For large infrastructure projects or jobs that require high-volume asphalt production, a mobile plant may not be sufficient to meet the demand.

- Potential for Reduced Quality Control

Mobile plants are generally less sophisticated than fixed plants in terms of technology and automation. While they can still produce high-quality asphalt, the mix may not always meet the precise standards required for larger or more complex projects. However, advancements in mobile plant technology are continually improving this aspect.

- Limited Long-Term Use

For contractors involved in long-term, large-scale road construction, the need for a permanent solution often outweighs the benefits of a mobile asphalt plant. The limited production capacity and the need for frequent relocation can make it less cost-effective in the long term for such projects.

[edit] Which Option Is Best for Project Contractors?

The choice between a fixed and a mobile asphalt plant largely depends on the specific requirements of your project. Here are some factors to consider when making your decision:

If you’re working on a large, long-term project with a continuous need for asphalt, a fixed plant might be the better choice. For smaller, shorter-term projects or those with multiple job sites, a mobile asphalt plant offers greater flexibility and cost savings.

- Budget

For contractors working with limited budgets, the lower upfront cost of a mobile asphalt plant, including options like a mini asphalt plant, may be more feasible. However, if your company has the capital to invest in a fixed plant, the long-term benefits of high production capacity may justify the higher initial expense.

- Location

If your construction project is located in a remote area or spread over multiple sites, a mobile asphalt plant can help reduce transportation costs and improve overall project efficiency. For projects in urban areas or locations with easy access to fixed plants, a stationary plant may be more suitable.

[edit] Conclusion

Both fixed and mobile asphalt plants have their unique benefits and challenges, making the choice between them highly dependent on your specific project needs. Fixed plants are ideal for large, long-term operations, while mobile plants offer the flexibility and cost-effectiveness needed for smaller, more dynamic projects.

By evaluating the scale, duration, and location of your project, you can make an informed decision that aligns with your company's goals and budget, ensuring that you choose the most efficient and cost-effective asphalt production solution.

Featured articles and news

The Building Safety Forum at the Installershow 2025

With speakers confirmed for 24 June as part of Building Safety Week.

The UK’s largest air pollution campaign.

Future Homes Standard, now includes solar, but what else?

Will the new standard, due to in the Autumn, go far enough in terms of performance ?

BSRIA Briefing: Cleaner Air, Better tomorrow

A look back at issues relating to inside and outside air quality, discussed during the BSRIA briefing in 2023.

Restoring Abbotsford's hothouse

Bringing the writer Walter Scott's garden to life.

Reflections on the spending review with CIAT.

Retired firefighter cycles world to raise Grenfell funds

Leaving on 14 June 2025 Stephen will raise money for youth and schools through the Grenfell Foundation.

Key points for construction at a glance with industry reactions.

Functionality, visibility and sustainability

The simpler approach to specification.

Architects, architecture, buildings, and inspiration in film

The close ties between makers and the movies, with our long list of suggested viewing.

SELECT three-point plan for action issued to MSPs

Call for Scottish regulation, green skills and recognition of electrotechnical industry as part of a manifesto for Scottish Parliamentary elections.

UCEM becomes the University of the Built Environment

Major milestone in its 106-year history, follows recent merger with London School of Architecture (LSE).

Professional practical experience for Architects in training

The long process to transform the nature of education and professional practical experience in the Architecture profession following recent reports.

A people-first approach to retrofit

Moving away from the destructive paradigm of fabric-first.

International Electrician Day, 10 June 2025

Celebrating the role of electrical engineers from André-Marie Amperè, today and for the future.

New guide for clients launched at Houses of Parliament

'There has never been a more important time for clients to step up and ...ask the right questions'

The impact of recycled slate tiles

Innovation across the decades.

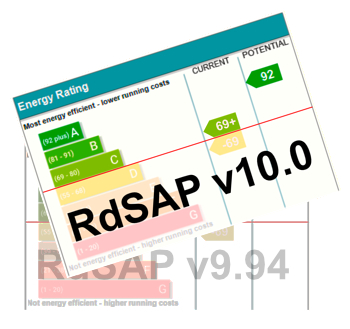

EPC changes for existing buildings

Changes and their context as the new RdSAP methodology comes into use from 15 June.