Breather membranes for buildings

Damp in buildings can cause a number of serious problems, such as:

- Damp patches.

- Mould growth, mildew, salts, staining and ‘tide marks’.

- Damage to surface finishes.

- Corrosion and decay of building fabric.

- Slip hazards.

- Frost damage.

- Poor performance of insulation.

- Damage to equipment, or electrical failure.

The most common causes of persistent damp in buildings are:

- Surface condensation.

- Interstitial condensation (condensation within the fabric of a building's construction, either on the surfaces of components that make up the fabric, or sometimes within the components themselves).

- Penetrating damp.

- Rising damp.

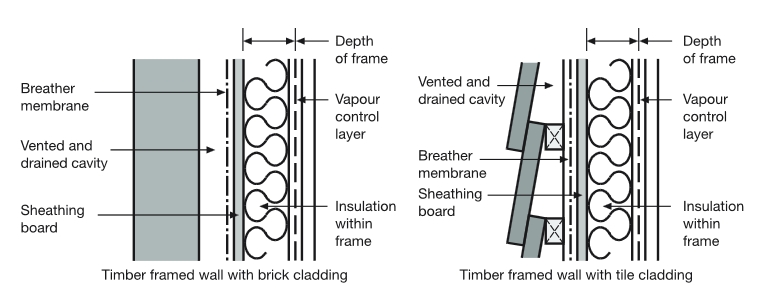

Breather membranes (or breathable membranes) are water resistant but vapour permeable. Typically they are used within external wall and roof constructions where the external cladding may not be completely water-tight or moisture resistant, such as in tiled roofs or framed wall constructions.

The membrane is located on the cold side of insulation and prevents moisture (as well as snow, wind, and contaminants such as dust) that may have been driven through the external cladding, from penetrating further into the structure. However, their air-permeability allows the structure to be ventilated, avoiding the build-up of interstitial condensation.

Any moisture that forms on the outside face of the membrane should be able to vent or drain to the outside.

Breather membranes can also improve the thermal efficiency of a building’s external envelope and can provide temporary protection from the weather during construction or repair works.

Generally, breathable membranes for wall constructions do not have to be as high a specification as those in roof constructions. In roofs, breathable membranes are required to resist wind uplift so that tiles are not dislodged by movement of the membrane.

In framed wall constructions, breathable membranes may sometimes be fitted during the manufacturing process, off site. Typically, wall constructions will also include a vapour barrier, on the warm side of insulation which prevents humid air from inside the building being driven to a point in the wall structure where it reaches its dew-point temperature and moisture condenses.

In roof constructions, breathable membranes may be supported or unsupported. The channel between fixings can be used to drain moisture to the eaves. Some breathable membranes have sufficient air-permeability that eaves and ridge ventilation of the roof is not necessary.

[edit] Related articles on Designing Buildings

Featured articles and news

A case study and a warning to would-be developers

Creating four dwellings... after half a century of doing this job, why, oh why, is it so difficult?

Reform of the fire engineering profession

Fire Engineers Advisory Panel: Authoritative Statement, reactions and next steps.

Restoration and renewal of the Palace of Westminster

A complex project of cultural significance from full decant to EMI, opportunities and a potential a way forward.

Apprenticeships and the responsibility we share

Perspectives from the CIOB President as National Apprentice Week comes to a close.

The first line of defence against rain, wind and snow.

Building Safety recap January, 2026

What we missed at the end of last year, and at the start of this...

National Apprenticeship Week 2026, 9-15 Feb

Shining a light on the positive impacts for businesses, their apprentices and the wider economy alike.

Applications and benefits of acoustic flooring

From commercial to retail.

From solid to sprung and ribbed to raised.

Strengthening industry collaboration in Hong Kong

Hong Kong Institute of Construction and The Chartered Institute of Building sign Memorandum of Understanding.

A detailed description from the experts at Cornish Lime.

IHBC planning for growth with corporate plan development

Grow with the Institute by volunteering and CP25 consultation.

Connecting ambition and action for designers and specifiers.

Electrical skills gap deepens as apprenticeship starts fall despite surging demand says ECA.

Built environment bodies deepen joint action on EDI

B.E.Inclusive initiative agree next phase of joint equity, diversity and inclusion (EDI) action plan.

Recognising culture as key to sustainable economic growth

Creative UK Provocation paper: Culture as Growth Infrastructure.

Comments

It would be great to have a breakdown of the different types of breather membranes, in particular the difference between microporous and monolithic membranes.