Asbestos management

Contents |

[edit] Introduction

Asbestos was fully banned in the UK in 1999, but it remains the single greatest cause of work-related deaths in the UK. The time between exposure and disease varies widely.

Refurbishment, alteration and demolition projects are affected by asbestos in buildings. Material condition and type are key factors in the danger presented. For more information see: Asbestos.

[edit] Management requirements

The Control of Asbestos Regulations 2012 creates a legal duty to manage asbestos. If asbestos is present, or is presumed to be present, then it must be managed appropriately. This includes making and keeping an up-to-date record of the location and condition of materials which are presumed to contain asbestos, and preparing a management plan that sets out how the risks from these materials will be managed.

An asbestos survey provides accurate information about the location, amount, type and condition of any asbestos-containing materials (ACMs). The findings of a survey should be detailed in a survey report, which can then be used to help prepare an asbestos register (or asbestos risk register) which will be a key component of the management plan.

[edit] Lack of awareness

Figures published by the Institution of Occupational Safety and Health (IOSH) in April 2018 indicated that around a third (32%) of the respondents to its survey had never checked the asbestos register before starting work on a new site. Nearly half of those who had not checked the register were not even aware there was one, and nearly one in five (18%) said they would not be clear what to do if they discovered asbestos while working on a site.

This underscores the importance of a well defined (and well publicised) asbestos management plan that clarifies procedures that should be followed to avoid exposure incidents. The plan can:

- Teach workers how to avoid exposure.

- Provide basic training for anyone who may have to handle asbestos containing materials.

- Describe which activities could disturb asbestos.

- Document when asbestos materials are inspected and note any change in condition.

All personnel should be notified of any ACMs that could pose a risk. They should also be made aware of any changes to the management plan.

[edit] Operations and maintenance programme

After a management plan is in place, it is important to create an operations and maintenance (O&M) programme. This programme will ideally establish facility specific best practices to support worker behaviours that will keep ACM in a safe condition. It also provides appropriate procedures, should it become necessary to clean up damaged materials. Finally, the programme establishes a monitoring method that tracks the condition of ACM - until all ACM has been removed from the premises.

[edit] Aspects of an asbestos O&M programme

An O&M programme can include, but not be limited to, these components:

[edit] Notification of personnel

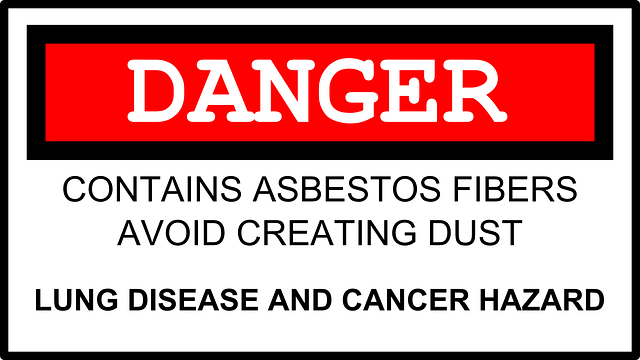

Employees, contractors and other site personnel must be notified as to the location and physical condition of asbestos and warned not to disturb or damage it. Personnel can be notified through a range of methods, depending on how many people must be made aware of the situation. Written notices can be distributed, postings or signs can be placed in central locations and meetings can be held to present essential information to those who run the greatest risk of coming in contact with ACM.

The information may include the following messages about the presence of ACM:

- Asbestos has been identified in areas where materials could be disturbed or damaged.

- Asbestos is a health hazard only when inhaled or ingested. Its presence alone is not hazardous.

- Maintenance personnel must take special precautions to clean up any debris and to protect against disturbing ACM.

- All ACM are periodically inspected. Additional precautions and protective measures will be employed if needed.

- All known ACM should be identified with warning signs that can be directly attached to the materials. They can also be placed at the entrances to areas where ACM exists.

[edit] Training

Prior to the development of the asbestos O&M programme, key personnel will require asbestos training themselves. Then maintenance personnel will require training in order to perform cleaning, general maintenance and emergency response repair tasks safely.

[edit] Worker protection

A worker protection programme includes medical surveillance, personal protection equipment (PPE) including respirators and protective clothing and exposure monitoring.

[edit] Work permit system

The O&M programme should include a system designed to control any and all work activities that could potentially disturb ACM. Managers should review requests to determine if asbestos is present in a work area, and then the asbestos survey report should be reviewed. An inspection should also take place to ensure no significant changes have occurred since the survey was conducted.

If asbestos is found in a work area, properly trained personnel can be assigned to remove the materials and transport it safely away from the premises.

[edit] Asbestos work practices

Routine maintenance activities can potentially damage or disturb ACM. Workers must be made aware of this through training that includes procedures to address possible asbestos hazards on the site.

Work practices must be developed for emergency response and planned renovation and demolition activities. These approaches should reflect the possibility that ACM will be damaged or disturbed and then categorised appropriately in the following manner:

- Contact with asbestos is unlikely.

- Accidental disturbance or damage is likely.

- Small amounts of ACM may be damaged or disturbed.

- Large amounts of ACM may be damaged or disturbed.

[edit] Periodic surveillance

A visual reinspection of all ACM should be conducted to document any changes in the condition of those materials. Managers should create schedules for routine inspections and periodic reinspections related to the degree of maintenance, construction and other activity that may take place in areas where ACM may be present. The results of the inspections, and any corrective measures taken based on the findings, should be formally documented.

[edit] Related articles on Designing Buildings Wiki

- Asbestos.

- Asbestos cement.

- Asbestos register.

- Asbestos surveyor.

- Control of Asbestos Regulations 2012 CAR12.

- Demolition.

- Failure to mention asbestos.

- Five signs you are at risk of asbestos poisoning at work.

- Managing risks in existing buildings: An overview of UK risk-based legislation for commercial and industrial premises (FB 86).

Featured articles and news

A case study and a warning to would-be developers

Creating four dwellings for people to come home to... after half a century of doing this job, why, oh why, is it so difficult?

Reform of the fire engineering profession

Fire Engineers Advisory Panel: Authoritative Statement, reactions and next steps.

Restoration and renewal of the Palace of Westminster

A complex project of cultural significance from full decant to EMI, opportunities and a potential a way forward.

Apprenticeships and the responsibility we share

Perspectives from the CIOB President as National Apprentice Week comes to a close.

The first line of defence against rain, wind and snow.

Building Safety recap January, 2026

What we missed at the end of last year, and at the start of this...

National Apprenticeship Week 2026, 9-15 Feb

Shining a light on the positive impacts for businesses, their apprentices and the wider economy alike.

Applications and benefits of acoustic flooring

From commercial to retail.

From solid to sprung and ribbed to raised.

Strengthening industry collaboration in Hong Kong

Hong Kong Institute of Construction and The Chartered Institute of Building sign Memorandum of Understanding.

A detailed description from the experts at Cornish Lime.

IHBC planning for growth with corporate plan development

Grow with the Institute by volunteering and CP25 consultation.

Connecting ambition and action for designers and specifiers.

Electrical skills gap deepens as apprenticeship starts fall despite surging demand says ECA.

Built environment bodies deepen joint action on EDI

B.E.Inclusive initiative agree next phase of joint equity, diversity and inclusion (EDI) action plan.

Recognising culture as key to sustainable economic growth

Creative UK Provocation paper: Culture as Growth Infrastructure.

Futurebuild and UK Construction Week London Unite

Creating the UK’s Built Environment Super Event and over 25 other key partnerships.

Welsh and Scottish 2026 elections

Manifestos for the built environment for upcoming same May day elections.

Advancing BIM education with a competency framework

“We don’t need people who can just draw in 3D. We need people who can think in data.”