Firring

A firring is a thin strip of timber (or ‘batten’) that has been cut along its length diagonally so that it tapers, with one end deeper than the other. Firrings are used in the construction of flat roofs to create a fall, ensuring that water runs to the lower side. Typically they are designed to a fall of 1:40, which given on-site inaccuracies should result in a minimum fall of 1:80 in the finished construction.

Firrings are sometimes referred to as furring strips or furrings, when applied more generally raise building elements, such as in roof structures. In the US these might be referred to as strapping.

They are manufactured by cutting at an angle along the length of a timber batten. As this requires specialist cutting equipment, firrings are often manufactured off site. Commonly available sizes have a maximum cross section of 47mm x 50mm, 47mm x 75mm and 47 x 100mm

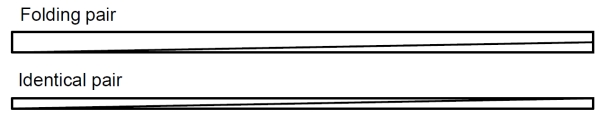

Firrings are cut in pairs, with the pieces on both sides of the cut line being used so as to minimise waste. They can be cut in identical pairs or folding pairs. Identical pairs are the same when cut, whereas a folding pair are cut to form a continuous fall when placed end to end.

NB: The term metal furring system or MF System refers to a technique for creating a seamless plaster internal finish with a void behind for the installation of services. Plasterboard is fixed directly to the concealed metal furrings. This can be used as an alternative to traditional timber batten construction for walls and ceilings.

For more information, see Metal furring system.

[edit] Related articles on Designing Buildings

Featured articles and news

For the World Autism Awareness Month of April.

70+ experts appointed to public sector fire safety framework

The Fire Safety (FS2) Framework from LHC Procurement.

Project and programme management codes of practice

CIOB publications for built environment professionals.

Sustainable development concepts decade by decade.

The regenerative structural engineer

A call for design that will repair the natural world.

Buildings that mimic the restorative aspects found in nature.

CIAT publishes Principal Designer Competency Framework

For those considering applying for registration as a PD.

BSRIA Building Reg's guidance: The second staircase

An overview focusing on aspects which most affect the building services industry.

Design codes and pattern books

Harmonious proportions and golden sections.

Introducing or next Guest Editor Arun Baybars

Practising architect and design panel review member.

Quick summary by size, shape, test, material, use or bonding.

Types of rapidly renewable content

From forestry to agricultural crops and their by-products.

Terraced houses and the public realm

The discernible difference between the public realm of detached housing and of terraced housing.