Firring

A firring is a thin strip of timber (or ‘batten’) that has been cut along its length diagonally so that it tapers, with one end deeper than the other. Firrings are used in the construction of flat roofs to create a fall, ensuring that water runs to the lower side. Typically they are designed to a fall of 1:40, which given on-site inaccuracies should result in a minimum fall of 1:80 in the finished construction.

Firrings are sometimes referred to as furring strips or furrings, when applied more generally raise building elements, such as in roof structures. In the US these might be referred to as strapping.

They are manufactured by cutting at an angle along the length of a timber batten. As this requires specialist cutting equipment, firrings are often manufactured off site. Commonly available sizes have a maximum cross section of 47mm x 50mm, 47mm x 75mm and 47 x 100mm

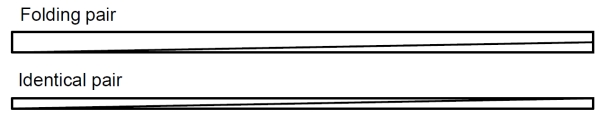

Firrings are cut in pairs, with the pieces on both sides of the cut line being used so as to minimise waste. They can be cut in identical pairs or folding pairs. Identical pairs are the same when cut, whereas a folding pair are cut to form a continuous fall when placed end to end.

NB: The term metal furring system or MF System refers to a technique for creating a seamless plaster internal finish with a void behind for the installation of services. Plasterboard is fixed directly to the concealed metal furrings. This can be used as an alternative to traditional timber batten construction for walls and ceilings.

For more information, see Metal furring system.

[edit] Related articles on Designing Buildings

Featured articles and news

A case study and a warning to would-be developers

Creating four dwellings... after half a century of doing this job, why, oh why, is it so difficult?

Reform of the fire engineering profession

Fire Engineers Advisory Panel: Authoritative Statement, reactions and next steps.

Restoration and renewal of the Palace of Westminster

A complex project of cultural significance from full decant to EMI, opportunities and a potential a way forward.

Apprenticeships and the responsibility we share

Perspectives from the CIOB President as National Apprentice Week comes to a close.

The first line of defence against rain, wind and snow.

Building Safety recap January, 2026

What we missed at the end of last year, and at the start of this...

National Apprenticeship Week 2026, 9-15 Feb

Shining a light on the positive impacts for businesses, their apprentices and the wider economy alike.

Applications and benefits of acoustic flooring

From commercial to retail.

From solid to sprung and ribbed to raised.

Strengthening industry collaboration in Hong Kong

Hong Kong Institute of Construction and The Chartered Institute of Building sign Memorandum of Understanding.

A detailed description from the experts at Cornish Lime.

IHBC planning for growth with corporate plan development

Grow with the Institute by volunteering and CP25 consultation.

Connecting ambition and action for designers and specifiers.

Electrical skills gap deepens as apprenticeship starts fall despite surging demand says ECA.

Built environment bodies deepen joint action on EDI

B.E.Inclusive initiative agree next phase of joint equity, diversity and inclusion (EDI) action plan.

Recognising culture as key to sustainable economic growth

Creative UK Provocation paper: Culture as Growth Infrastructure.