Soldering

Contents |

[edit] Introduction

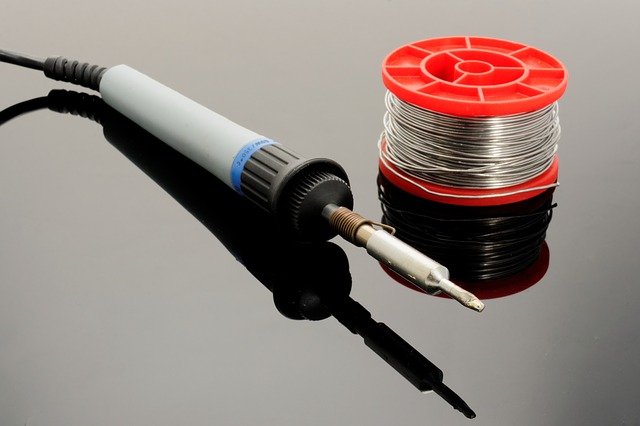

Soldering is a method of permanently joining or seaming together pieces of metal. It can be used to repair small holes in metal, assemble electronic components, join pipes and so on.

[edit] Three elements of soldering

The soldering process involves three main elements - heat, filler (or solder) and flux.

[edit] Heat

Heat is generally created by a soldering iron or blowtorch. The most common types of soldering irons are electrically powered, although there are some that can be heated in a fire. A propane blowtorch tends to be more effective at heating thick metal quickly. In some instances, a hot air gun can be used for soft soldering projects while a furnace can be used in hard soldering to heat the components until the solder melts.

There are other industrial soldering methods, including:

- Electrical resistance soldering using tungsten or copper electrodes.

- Induction soldering using high frequency alternating current.

- Ultrasonic soldering using ultrasonic vibrations transmitted by a nickel rod through the solder.

[edit] Filler materials

These are special alloys known as solder. Solder is available as rods, wires, strips, sheets or other forms. The type of solder used in the process must have a melting point that is lower than that of the metals being joined.

Soft solder is usually a mixture of lead and tin. Soft solder tends to use heat from a soldering iron or blowtorch. Soft solder is typically used for joining elements such as copper plumbing fittings.

Hard solders generally incorporate brass solders (such as copper-zinc alloys), silver solders, copper solders, nickel-silver solders, solders for light alloys and so on. Hard solder also uses heat from a soldering iron or blowtorch, but it can also use other sources of heat (such as a furnace).

[edit] Flux

Flux creates a chemical barrier to prevent the formation of oxides (which can impede the bonding process). There is liquid flux (referred to as corrosive or active flux) that must be washed away from the surface once the solder hardens and becomes solid. There is also passive flux, which is a paste that cannot be washed away entirely. Therefore, this method is primarily used for purposes (such as electrical connections or copper plumbing joints) where it can do a sufficient job of excluding oxide without requiring it to be dissolved entirely.

Some types of wire solder incorporate flux into their core.

[edit] Combinations of metal, solder and flux

Some of the most commonly found combinations of materials used in the standard soldering process are:

| Types of metal | Types of solder | Types of flux |

| Silver, brass, copper, nickel | Silver solder | borax cone ground up and mixed with water in a borax dish. |

| Gold | Gold solder | borax cone ground up and mixed with water in a borax dish. |

| Cast iron | Brazing solder (see below) | special flux from copper (or cuprous) oxide. |

[edit] Brazing

Brazing is a method of hard soldering that involves a copper-zinc alloy as the filler material and borax as the flux. Brazing requires extremely high temperatures (much higher than those created through soft soldering techniques).

Dip brazing is a technique in which metal is immersed in the molten jointing medium. It is widely used in industrial mass-production processes.

[edit] Related articles on Designing Buildings

Featured articles and news

Reform of the fire engineering profession

Fire Engineers Advisory Panel: Authoritative Statement, reactions and next steps.

Restoration and renewal of the Palace of Westminster

A complex project of cultural significance from full decant to EMI, opportunities and a potential a way forward.

Apprenticeships and the responsibility we share

Perspectives from the CIOB President as National Apprentice Week comes to a close.

The first line of defence against rain, wind and snow.

Building Safety recap January, 2026

What we missed at the end of last year, and at the start of this...

National Apprenticeship Week 2026, 9-15 Feb

Shining a light on the positive impacts for businesses, their apprentices and the wider economy alike.

Applications and benefits of acoustic flooring

From commercial to retail.

From solid to sprung and ribbed to raised.

Strengthening industry collaboration in Hong Kong

Hong Kong Institute of Construction and The Chartered Institute of Building sign Memorandum of Understanding.

A detailed description from the experts at Cornish Lime.

IHBC planning for growth with corporate plan development

Grow with the Institute by volunteering and CP25 consultation.

Connecting ambition and action for designers and specifiers.

Electrical skills gap deepens as apprenticeship starts fall despite surging demand says ECA.

Built environment bodies deepen joint action on EDI

B.E.Inclusive initiative agree next phase of joint equity, diversity and inclusion (EDI) action plan.

Recognising culture as key to sustainable economic growth

Creative UK Provocation paper: Culture as Growth Infrastructure.

Futurebuild and UK Construction Week London Unite

Creating the UK’s Built Environment Super Event and over 25 other key partnerships.

Welsh and Scottish 2026 elections

Manifestos for the built environment for upcoming same May day elections.

Advancing BIM education with a competency framework

“We don’t need people who can just draw in 3D. We need people who can think in data.”