Infill panel walls

Contents |

[edit] Introduction

Infill panel walls are a form of cladding built between the structural members of a building. The structural frame provides support for the cladding system, and the cladding provides separation of the internal and external environments. Infill walling is different to other forms of cladding panel in that it is fixed between framing members rather than being attached to the outside of the frame.

Infill panel walls are not considered to be load bearing, although they are required to resist wind loads applied to the façade, as well as supporting their own weight. Other functional requirements for infill panel walls include:

- They are self-supporting between structural framing members.

- They provide weather-resistance.

- They provide thermal and sound insulation.

- The provide fire resistance.

- They provide sufficient openings for natural ventilation and glazing.

- They can accommodate differential movements between themselves and the frame.

[edit] Types of infill panel walls

Traditionally, infill panel walls used brick/masonry or timber; however, these are more time consuming than modern alternatives and have been largely replaced by lightweight steel C-sections that span between floors and around openings.

[edit] Brick infill panels

These can be constructed from clay bricks or concrete blocks, in a solid or cavity form. The same principles of solid and cavity wall construction apply to infill panel walls. They can be tied to columns using wall ties cast at 300 mm centres, or located in anchor slots.

[edit] Concrete infill panels

These are usually large precast concrete panels that are the height of one storey and of a width dictated by the spacing of the frame. They can be either top-hung or bottom-supported. Panels that are integral may be clad in other materials, most typically stone.

The maximum panel size is generally restricted by the transport considerations and crane lifting capacity.

[edit] Timber infill panels

Timber sections are cut to length – typically 90 and 140 mm depth to span 2.4 - 3.6 m between floors – and placed at 400 or 600 mm spacings.

The disadvantage of using timber in place of steel is that it has less strength and cannot be used in tall sections or walls with large openings for doors or windows.

[edit] Lightweight steel infill panels

Multi-storey framed construction often uses lightweight steel for infill panel walls that support the external cladding. The panels are fixed between the structural horizontal and vertical members of the frame, and can incorporate architectural features such as large windows, parapets, and so on. The panels are lightweight, and are quick and easy to instal.

The size and thickness of the steel sections can be varied according to the façade wall height and windloads. Typically, C-sections and U-sections of 75-100 mm depth are cold roll-formed from galvanized steel strip of 1.2-3.2 mm thickness. Pairs of C-sections may be used next to large openings, and are typically placed at 400 or 600 mm spacings.

[edit] Related articles on Designing Buildings

Featured articles and news

CIOB report; a blueprint for SDGs and the built environment

Pairing the Sustainable Development Goals with projects.

Latest Build UK Building Safety Regime explainer published

Key elements in one short, now updated document.

UKGBC launch the UK Climate Resilience Roadmap

First guidance of its kind on direct climate impacts for the built environment and how it can adapt.

CLC Health, Safety and Wellbeing Strategy 2025

Launched by the Minister for Industry to look at fatalities on site, improving mental health and other issues.

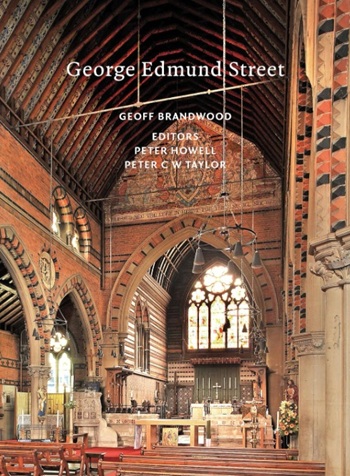

One of the most impressive Victorian architects. Book review.

Common Assessment Standard now with building safety

New CAS update now includes mandatory building safety questions.

RTPI leader to become new CIOB Chief Executive Officer

Dr Victoria Hills MRTPI, FICE to take over after Caroline Gumble’s departure.

Social and affordable housing, a long term plan for delivery

The “Delivering a Decade of Renewal for Social and Affordable Housing” strategy sets out future path.

A change to adoptive architecture

Effects of global weather warming on architectural detailing, material choice and human interaction.

The proposed publicly owned and backed subsidiary of Homes England, to facilitate new homes.

How big is the problem and what can we do to mitigate the effects?

Overheating guidance and tools for building designers

A number of cool guides to help with the heat.

The UK's Modern Industrial Strategy: A 10 year plan

Previous consultation criticism, current key elements and general support with some persisting reservations.

Building Safety Regulator reforms

New roles, new staff and a new fast track service pave the way for a single construction regulator.

Architectural Technologist CPDs and Communications

CIAT CPD… and how you can do it!

Cooling centres and cool spaces

Managing extreme heat in cities by directing the public to places for heat stress relief and water sources.

Winter gardens: A brief history and warm variations

Extending the season with glass in different forms and terms.

Restoring Great Yarmouth's Winter Gardens

Transforming one of the least sustainable constructions imaginable.