Laminated glass

Contents |

[edit] Introduction

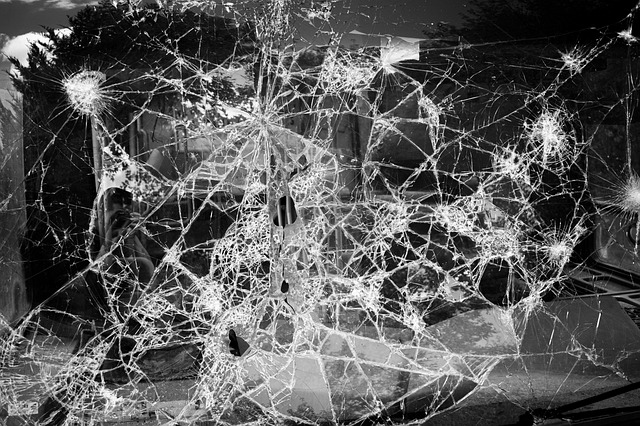

Laminated glass (sometimes called toughened laminated glass) comprises two or more layers of glass sandwiched together with tear-resistant plastic film interlayers (usually polyvinyl butyral (PVB) or ethylene-vinyl acetate (EVA). The aim is to create a glass composite which can absorb the energy of a person or object that strikes it, preventing penetration of the pane and potential injuries that might result from flying fragments of broken glass.

An additional benefit of laminated glass is that most ultraviolet radiation can be blocked by the PVB or EVA interlayer. Thermoset EVA layers can block up to 99.9% of UV rays.

[edit] Applications

Laminated glass can be used for safety or security reasons. It is used for architectural applications where for example, the glass could fall from a height and shatter, and also for roof, balcony and terrace balustrading, as well as for skylights. It can also be used as a decorative material due to the wide variety of interlayers available, e.g coloured, textured, meshed or patterned. It is particularly useful for windows and shopfronts in areas prone to hurricanes.

In addition to flat sheets, it can be supplied in curved sections, as may be required for car windscreens.

[edit] Manufacture

Bonding together the alternating layers of, typically annealed glass, and plastic film is usually achieved through the use of heat and pressure created by an autoclave.

Manufacture can involve using heat-strengthened glass, which, when it breaks, does so into large pieces held in the frame by the PVB inter-layer. Or it can be made from tempered glass, where the sheet may fall out of the frame but will mostly stay together due to the interlayer.

Digital printing for special effects can be created by printing on to the glass prior to laminating or printing onto the interlayer.

[edit] Configurations

Laminated glass is available in various thicknesses and configurations. A typical glass-layers configuration can comprise 2.5mm glass – 0.38mm interlayer – 2.5mm glass, resulting in ‘5.38 laminated glass’.

Thicker glass and multiple laminates giver a stronger product. Thicker configurations such as double– or triple-laminate with interlayers (int) can include the following:

[edit] Double laminate:

- 6mm - int - 6mm.

- 8mm - int - 8mm.

- 10mm - int - 10mm.

[edit] Triple laminate:

- 6mm - int - 6mm - int -6mm.

- 8mm - int - 8mm - int -8mm.

- 10mm - int - 10mm - int -10mm.

The cockpit of an aircraft such as a Boeing 747 may include a triple-laminated glass construction comprising three layers of 4mm toughened glass with 2.6mm PVB layers in between, making a total glass thickness of 17.2mm.

[edit] Related articles on Designing Buildings Wiki

- BFRC window rating scheme.

- BREEAM Visual comfort View out.

- Curved glass.

- Daylit space.

- Domestic windows.

- Double glazing.

- Emissivity.

- Float glass process.

- Glass.

- Low-E glass.

- Overheating.

- Patent glazing.

- Preventing overheating.

- R-value.

- Rights to light.

- Safety glass.

- Secondary glazing.

- Security glazing.

- Structural glass assembly.

- Suction lifter.

- Types of window.

- U-value.

- Window.

Featured articles and news

A case study and a warning to would-be developers

Creating four dwellings for people to come home to... after half a century of doing this job, why, oh why, is it so difficult?

Reform of the fire engineering profession

Fire Engineers Advisory Panel: Authoritative Statement, reactions and next steps.

Restoration and renewal of the Palace of Westminster

A complex project of cultural significance from full decant to EMI, opportunities and a potential a way forward.

Apprenticeships and the responsibility we share

Perspectives from the CIOB President as National Apprentice Week comes to a close.

The first line of defence against rain, wind and snow.

Building Safety recap January, 2026

What we missed at the end of last year, and at the start of this...

National Apprenticeship Week 2026, 9-15 Feb

Shining a light on the positive impacts for businesses, their apprentices and the wider economy alike.

Applications and benefits of acoustic flooring

From commercial to retail.

From solid to sprung and ribbed to raised.

Strengthening industry collaboration in Hong Kong

Hong Kong Institute of Construction and The Chartered Institute of Building sign Memorandum of Understanding.

A detailed description from the experts at Cornish Lime.

IHBC planning for growth with corporate plan development

Grow with the Institute by volunteering and CP25 consultation.

Connecting ambition and action for designers and specifiers.

Electrical skills gap deepens as apprenticeship starts fall despite surging demand says ECA.

Built environment bodies deepen joint action on EDI

B.E.Inclusive initiative agree next phase of joint equity, diversity and inclusion (EDI) action plan.

Recognising culture as key to sustainable economic growth

Creative UK Provocation paper: Culture as Growth Infrastructure.

Futurebuild and UK Construction Week London Unite

Creating the UK’s Built Environment Super Event and over 25 other key partnerships.

Welsh and Scottish 2026 elections

Manifestos for the built environment for upcoming same May day elections.

Advancing BIM education with a competency framework

“We don’t need people who can just draw in 3D. We need people who can think in data.”