Choosing A Continuous Tyre Pyrolysis Plant And Its Particular Importance

Contents |

[edit] Introduction

Generally, continuous tyre pyrolysis plant can work with rubber, waste tyres, medical waste, plastic, and oil sludge.

[edit] The Technical Advantages of a Continuous Tyre Pyrolysis Plant

1. Manageable electrical control system. Typically, this control system has a pressure gauge, thermometer, an unexpected emergency stop device, etc. It’s possible to monitor the working condition of your entire plant to be sure the machine is running optimally.

2. Screw feeding sealing system. The machine implements screw feeding sealing system technology and this technology will most likely stop the warmth from spreading. Furthermore, this screw technique ensures uniform feeding.

3. Unique dedusting system. Basically, this means that it produces zero-emission pollution. The environmental standard is stricter in some countries. Typically, the dedusting system will occur in three steps to ensure the discharged waste smoke adheres to the relevant emission requirements. These three procedures include ceramic ring adsorption, water rinsing, and water spraying.

In order to guarantee safety and cost-effectiveness for customers, this waste tire pyrolysis plant comes with a circulation home heating system, a moving horizontal pyrolysis reactor, a strong dedusting system, etc.

[edit] Various Uses of Final Pyrolysis Products

[edit] Tyre oil

- It can be very helpful as industrial fuel materials when it comes to burning

- It may help with relieving energy crisis

- If further refined to gasoline or diesel by a waste oil distillation machine, this oil could be beneficial in low-speed engines, digging machines, loading machines or road rollers, etc.

[edit] Carbon black

- It might be useful as fuel or construction bricks with clay

- It can be further made into briquettes or pellets for burning as well as further processed to create cable jackets, pipes, etc.

[edit] 3. Steel wire

[edit] Operation

- Pre-treatment for the waste materials is essential before entering the pyrolysis process. A tyre shredder machine must crush tyres into 30-5-mm pieces. It is also required to crash the plastics, particularly when they’re large and rigid. If the humidity of medical waste and plastics is quite high, it uses a dryer.

- Having been pretreated, feed the waste materials in to the reactor. Make sure the feeding inlet door is sealed tightly, and be sure there’s no gas leakage.

- By making use of wood, fuel gas, charcoal, coal, etc. as heating materials, heat the pyrolysis reactor gradually.

- The condensing system receives the oil gas from the reactor and condenses it to liquid oil.

- Using a safety device, the gas that can’t be liquefied will be sent back to the combustion system.

- Typically, the carbon black and steel wire will likely be discharged automatically.

Featured articles and news

A people-first approach to retrofit

Moving away from the destructive paradigm of fabric-first.

International Electrician Day, 10 June 2025

Celebrating the role of electrical engineers from André-Marie Amperè, today and for the future.

New guide for clients launched at Houses of Parliament

'There has never been a more important time for clients to step up and ...ask the right questions'

The impact of recycled slate tiles

Innovation across the decades.

EPC changes for existing buildings

Changes and their context as the new RdSAP methodology comes into use from 15 June.

Skills England publishes Sector skills needs assessments

Priority areas relating to the built environment highlighted and described in brief.

BSRIA HVAC Market Watch - May 2025 Edition

Heat Pump Market Outlook: Policy, Performance & Refrigerant Trends for 2025–2028.

Committing to EDI in construction with CIOB

Built Environment professional bodies deepen commitment to EDI with two new signatories: CIAT and CICES.

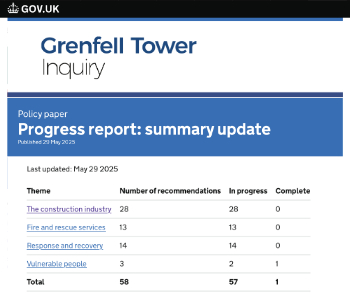

Government Grenfell progress report at a glance

Line by line recomendation overview, with links to more details.

An engaging and lively review of his professional life.

Sustainable heating for listed buildings

A problem that needs to be approached intelligently.

50th Golden anniversary ECA Edmundson apprentice award

Deadline for entries has been extended to Friday 27 June, so don't miss out!

CIAT at the London Festival of Architecture

Designing for Everyone: Breaking Barriers in Inclusive Architecture.

Mixed reactions to apprenticeship and skills reform 2025

A 'welcome shift' for some and a 'backwards step' for others.