Wood pellet processing plant

Contents |

[edit] Introduction

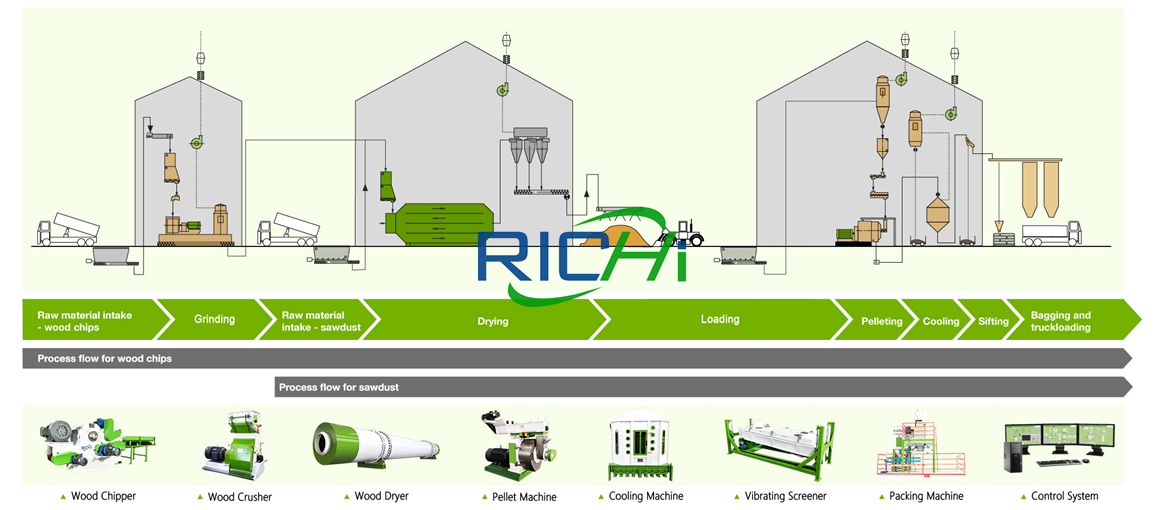

Wood pellet plants combine the complete procedure of biomass particle production, including all processes from drying out to squashing, granulation, cooling, testing and packaging. Plant may be arranged or customised in a variety of ways according to need as well as the degree of automation in cooling, packaging, and feeding.

[edit] Process

Appropriate raw materials are selected for natural fibres such as logs, branches, sawdust, rice husks, etc. These enter by conveyor belt and are sent to the wood hammer mill. On leaving in a crushed form these are directly send onward by the screw conveyor. This leads into the drum, similar to a clothes dryer, where materials are mixed with hot air. The dried material is accumulated by a cyclone separator, and then exits from the bottom of the airlock.

The next stage is the conditioner which is entered again via the screw conveyor, this conditions the material to the ideal level. Once achieving the intended moisture level the material is sent to the pelletising chamber, this performs a granulation process, with the material exiting as small round pellets of 2-12mm. The pellets then enter the cooler, drying the pellets to below 10%, and also cooling them to a regular temperature.

The remaining powder passes through the rotary category screener, which can separate out unqualified materials and granulate these once again. The screened pellets are loaded by an automated weighing device and then sealed by an automatic stitching device.

The complete set that makes up a wood pellet plant is not just timber pellet production equipment, it also a variety other treatment equipment according to the sort of resources and humidity.

If the raw materials arrives in larger sizes such as whole branches, it needs to be crushed into timber chips less than 5mm by a separate crusher, if it arrives smaller it can enter directly. If the humidity of the raw material is 15%-20%, it can enter the device directly, if it is higher than 20%, it has to be dried to 15-20% prior to granulation.

[edit] Renewable

As a renewable fuel, timber pellets have several advantages, such as high calorific worth, reduced emissions, huge particle proportion or compression after moulding, small volume, and combustion resistance. They have a higher level of processing than wood chips but due to their form can often be used more easily in small and large automated heaters, from industry to individual homes as an alternative fuel. Wood pellets can also utilise wood waste from saw mills and carpentry workshops.

Making use of wood pellets as a fuel is a realistic alternative environmental power resource that can help reduce carbon emissions, and has been used both in rural and urban locations.

[edit] Related articles on Designing Buildings

Featured articles and news

A case study and a warning to would-be developers

Creating four dwellings... after half a century of doing this job, why, oh why, is it so difficult?

Reform of the fire engineering profession

Fire Engineers Advisory Panel: Authoritative Statement, reactions and next steps.

Restoration and renewal of the Palace of Westminster

A complex project of cultural significance from full decant to EMI, opportunities and a potential a way forward.

Apprenticeships and the responsibility we share

Perspectives from the CIOB President as National Apprentice Week comes to a close.

The first line of defence against rain, wind and snow.

Building Safety recap January, 2026

What we missed at the end of last year, and at the start of this...

National Apprenticeship Week 2026, 9-15 Feb

Shining a light on the positive impacts for businesses, their apprentices and the wider economy alike.

Applications and benefits of acoustic flooring

From commercial to retail.

From solid to sprung and ribbed to raised.

Strengthening industry collaboration in Hong Kong

Hong Kong Institute of Construction and The Chartered Institute of Building sign Memorandum of Understanding.

A detailed description from the experts at Cornish Lime.

IHBC planning for growth with corporate plan development

Grow with the Institute by volunteering and CP25 consultation.

Connecting ambition and action for designers and specifiers.

Electrical skills gap deepens as apprenticeship starts fall despite surging demand says ECA.

Built environment bodies deepen joint action on EDI

B.E.Inclusive initiative agree next phase of joint equity, diversity and inclusion (EDI) action plan.

Recognising culture as key to sustainable economic growth

Creative UK Provocation paper: Culture as Growth Infrastructure.