Sustainable stone for the construction industry

|

| A look at stone from the point of view of sustainability, environmental impact and the effect on human health and wellbeing. |

Contents |

[edit] Characteristics of stone

[edit] No embedded carbon

Unlike many other building materials, the quarrying and fabrication of stone releases no embedded carbon, the only greenhouse gases released during quarrying are those used by the fuel to power the quarrying equipment.

[edit] Longevity

Stone is the ultimate long-term building material as the plethora of historical buildings still standing after millennia attests. Used both internally and externally, stone will last for as long as the building with very little maintenance.

[edit] No chemical treatment

Stone does not require treatment with chemicals to render it waterproof and in itself does not pollute or contribute to sick building syndrome, although care must be taken in the choice of fixing materials.

[edit] Recyclable

Stone can be recycled at the end of the building’s life. Building stone is reusable in another building, and any stone fittings that are broken or damaged in removal can be used for mosaics, construction ballast and so on.

[edit] Quarrying stone

To ensure maximum sustainability, specifiers should take care to choose a stone which comes from a plentiful resource rather than a rare or scarce one, and to pick a quarry that is responsibly managed from an environmental point of view as well as a human one.

The Stone Federation has established the Ethical Stone Register, which allows you to verify whether the stone contractor you are using is taking measures to ensure that the stone it buys has been sourced responsibly and ethically.

[edit] Transporting stone

Choosing stones from local quarries minimises the greenhouse gas emissions involved in transporting a heavy material. It also allows you to verify easily that the quarry is responsibly managed. Likewise, the choice of a stonemason close to the installation site ensures that CO2 emissions during transportation of the finished material are minimised.

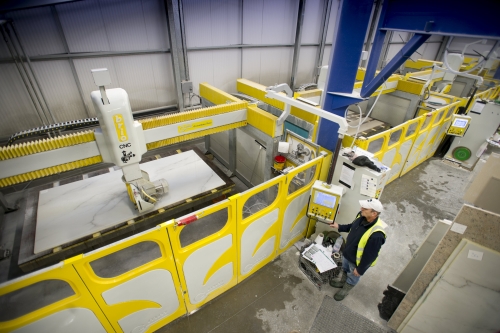

[edit] Stone fabrication

Select a stonemason that has an environmentally-friendly factory to ensure minimum harm to the environment. The fabrication of finished items from stone involves cutting and in some cases polishing which requires power and water. Modern factories will have taken steps to ensure that the majority of power needs are met by renewable sources and that rainwater harvesting and recycling of greywater makes them self-sufficient, rather than using-up precious resources. Recycling waste material is also a factor that should be taken into account.

[edit] Installing stone

The use of a fabricator close to the site will minimise CO2 emissions during transportation. The method of installation should also use techniques and materials that cause the least possible harm to the environment and to human health.

--Stonecircle 12:38, 03 Sep 2019 (BST)

[edit] Related articles on Designing Buildings Wiki

- Building with structural stone.

- Choosing stone.

- Defects in stonework.

- Finding stone to conserve historic buildings.

- Inspecting stone sample panels.

- Kentish ragstone.

- Masonry.

- Modern Stonemasonry.

- Natural stone cladding.

- Natural stone for Interiors.

- Natural stone tiles.

- Natural stone.

- Patio stone.

- Penarth Alabaster.

- Portland Stone.

- Sourcing indigenous stone.

- Sourcing stone to repair Exeter Cathedral.

- Stone dressing.

- Two New Ludgate Portland Stone Feature Wall.

- Types of stone.

- Use of Stone in Monks Lantern Weybridge.

[edit] External references

Featured articles and news

The need for a National construction careers campaign

Highlighted by CIOB to cut unemployment, reduce skills gap and deliver on housing and infrastructure ambitions.

AI-Driven automation; reducing time, enhancing compliance

Sustainability; not just compliance but rethinking design, material selection, and the supply chains to support them.

Climate Resilience and Adaptation In the Built Environment

New CIOB Technical Information Sheet by Colin Booth, Professor of Smart and Sustainable Infrastructure.

Turning Enquiries into Profitable Construction Projects

Founder of Develop Coaching and author of Building Your Future; Greg Wilkes shares his insights.

IHBC Signpost: Poetry from concrete

Scotland’s fascinating historic concrete and brutalist architecture with the Engine Shed.

Demonstrating that apprenticeships work for business, people and Scotland’s economy.

Scottish parents prioritise construction and apprenticeships

CIOB data released for Scottish Apprenticeship Week shows construction as top potential career path.

From a Green to a White Paper and the proposal of a General Safety Requirement for construction products.

Creativity, conservation and craft at Barley Studio. Book review.

The challenge as PFI agreements come to an end

How construction deals with inherited assets built under long-term contracts.

Skills plan for engineering and building services

Comprehensive industry report highlights persistent skills challenges across the sector.

Choosing the right design team for a D&B Contract

An architect explains the nature and needs of working within this common procurement route.

Statement from the Interim Chief Construction Advisor

Thouria Istephan; Architect and inquiry panel member outlines ongoing work, priorities and next steps.

The 2025 draft NPPF in brief with indicative responses

Local verses National and suitable verses sustainable: Consultation open for just over one week.

Increased vigilance on VAT Domestic Reverse Charge

HMRC bearing down with increasing force on construction consultant says.

Call for greater recognition of professional standards

Chartered bodies representing more than 1.5 million individuals have written to the UK Government.