Pattress Plates

A pattress plate is a name for an anchor plate for a wall tie.

The term “pattress” is believed to derive from the French patrice or patresse, referring to a backing or support plate.

Structurally speaking, they are the method by which the very concentrated force in a tensioned wall tie is spread out onto a wide area of material to avoid local failures. The tie may pass through a building or structure and have an anchor on both ends, or may be driven and fixed into embedded material, to help tie back a retaining wall.

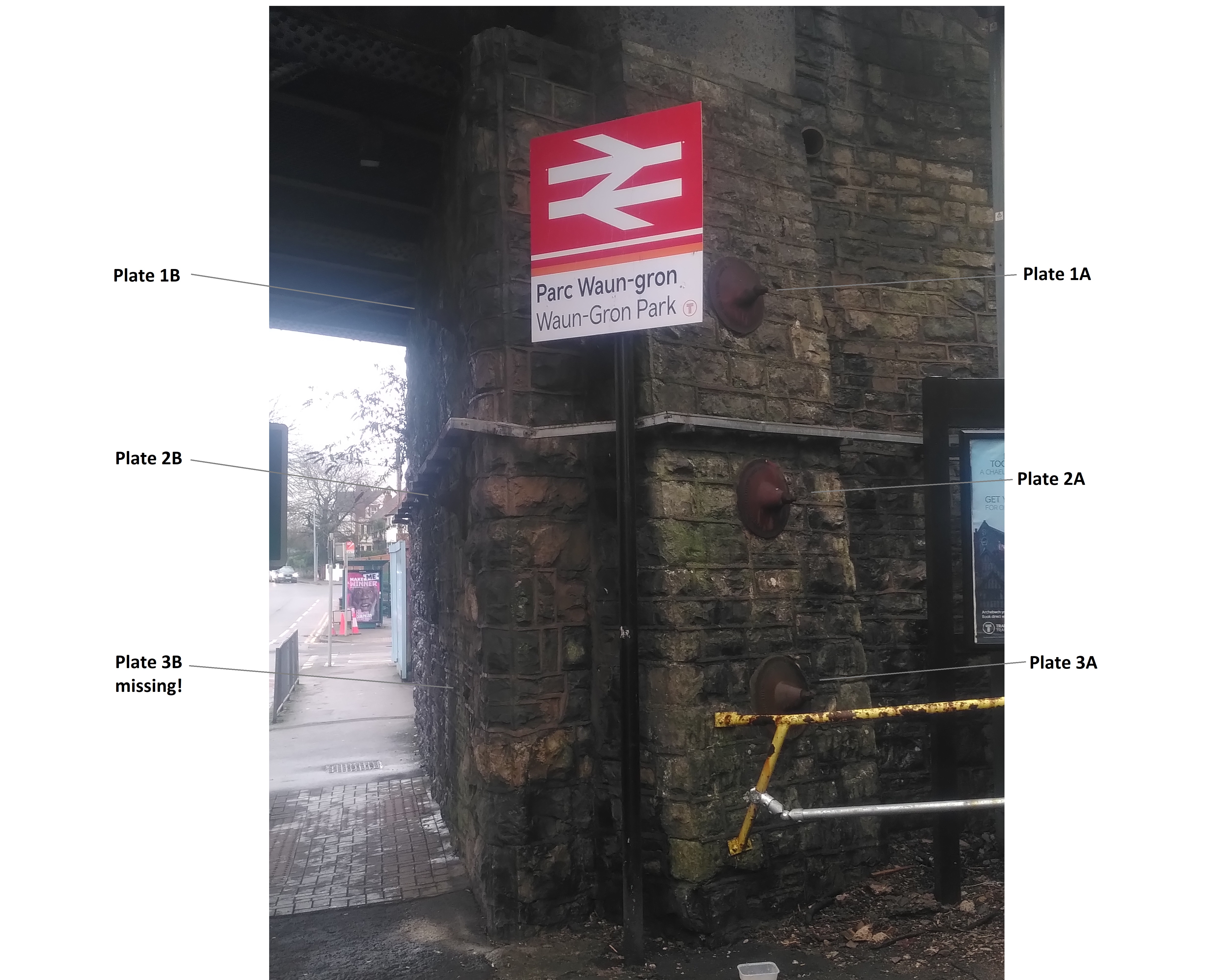

Sometimes, such as a railway viaduct that could not be excavated for installation, pattress plates may be present on both sides, but not actually connected. Their presence normally shows that a repair was carried out, but doesn't give much indication of the current condition of the structure. NDT (Non-Destructive Testing) measurement of the tie tension is difficult, and will need to consider seasonal temperature effects.

An example of a forged wrought iron pattress plate from Germany. S shapes are relatively common on agricultural buildings in the UK.

An example of a cast iron pattress plate from Wells-next-the-sea, Norfolk. The lack of thread and nut on this end of the wall tie suggests that tightening was applied at the other end, or inside the building.

An example of a 1985 ductile steel patress plate. The off center bulge is to accomadate and spread forces from a wall tie that is an an angle to the wall. In this case, it is tying through a corner.

In historic building practice pattress plates were used to:

- Provide a solid fixing where masonry was weak, uneven or friable.

- Distribute point loads over a larger area.

- Create a true, flat plane for ironmongery or fittings.

They were commonly made from timber, slate or metal and were often built into the wall or floor during construction, rather than being surface mounted.

In classical and medieval masonry embedded timber pattresses were used to:

- Anchor iron straps, tie bars and railings.

- Receive door furniture and shutter hinges.

- Support grilles, hooks and wall-mounted fittings.

In these contexts, the pattress plate acted as a sacrificial or replaceable interface between hard masonry and metal fixings, reducing damage to the surrounding stone or brickwork.

When gas lighting, bell systems and early electrical fittings were introduced in the nineteenth century, builders adopted the pattress plate concept. A timber pattress was fixed or built into the wall, plaster was run up to it or over it and the fitting was screwed into the pattress rather than the masonry.

This is still visible in Victorian buildings where switches or bell pulls are mounted to flush timber pattress plates, sometimes hidden beneath decorative plates.

This idea has developed into the modern concept of the patress box, positioned behind power sockets, light switches and other electrical fittings, and containing wiring, switches and other circuitry. This may sometimes be secured to a timber or plywood pattress.

See Pattress for more information.

[edit] Related articles on Designing Buildings

IHBC NewsBlog

Latest IHBC Issue of Context features Roofing

Articles range from slate to pitched roofs, and carbon impact to solar generation to roofscapes.

Three reasons not to demolish Edinburgh’s Argyle House

Should 'Edinburgh's ugliest building' be saved?

IHBC’s 2025 Parliamentary Briefing...from Crafts in Crisis to Rubbish Retrofit

IHBC launches research-led ‘5 Commitments to Help Heritage Skills in Conservation’

How RDSAP 10.2 impacts EPC assessments in traditional buildings

Energy performance certificates (EPCs) tell us how energy efficient our buildings are, but the way these certificates are generated has changed.

700-year-old church tower suspended 45ft

The London church is part of a 'never seen before feat of engineering'.

The historic Old War Office (OWO) has undergone a remarkable transformation

The Grade II* listed neo-Baroque landmark in central London is an example of adaptive reuse in architecture, where heritage meets modern sophistication.

West Midlands Heritage Careers Fair 2025

Join the West Midlands Historic Buildings Trust on 13 October 2025, from 10.00am.

Former carpark and shopping centre to be transformed into new homes

Transformation to be a UK first.

Canada is losing its churches…

Can communities afford to let that happen?

131 derelict buildings recorded in Dublin city

It has increased 80% in the past four years.