Spring materials

Contents |

[edit] Introduction

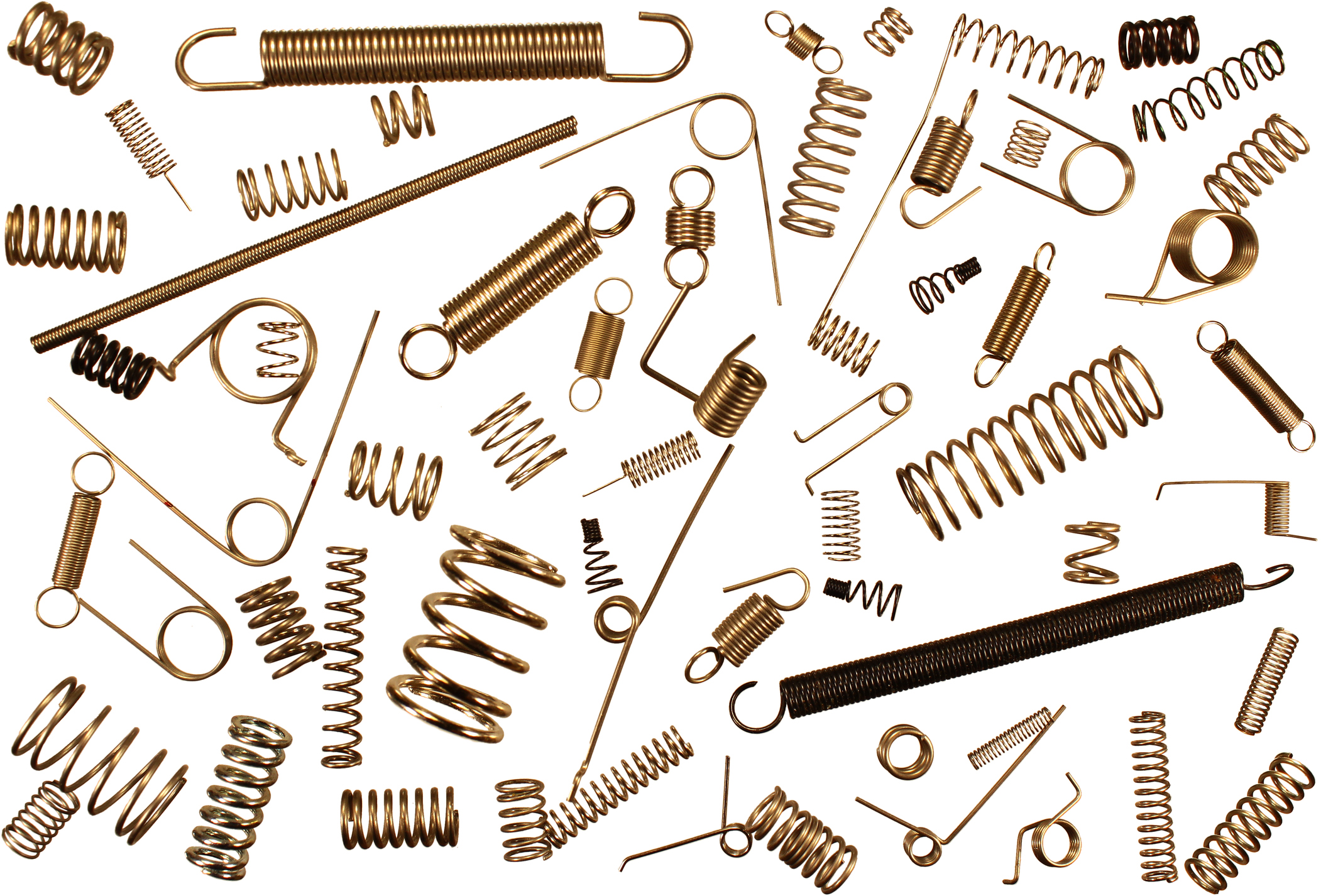

Springs are used in a huge range of different applications and are created in a variety of shapes, sizes and materials in order to fulfil different requirements. These different spring materials are used based on the requirements of the spring and present their own advantages and disadvantages.

While some materials boast a high resistance to corrosion, others may present a strength advantage. As technology advances, manufacturers and engineers are looking to create materials that are capable of being used in applications that may never have been necessary before, such as aerospace.

[edit] Stainless steel

Stainless steel is a commonly used alloy which is used in a huge range of applications. Stainless steels have a minimum of 10.5% chromium and other alloying elements are added to enhance the structure. This material is known for its excellent corrosion resistance so it is often used in architectural applications.

As a spring material, stainless steels are a popular choice due to their corrosion and heat resistance. These qualities mean that the alloy can maintain its integrity and remain strong in a number of applications where other materials may fail or degrade.

[edit] Alloy steels

Alloy steels are steels which have one or more alloying elements added to them in order to improve their properties. They may feature alloys such as manganese, silicon, nickel, titanium, copper, chromium or aluminium, to name a few.

Alloy steels often have improved strength, toughness, corrosion resistance, hardenability and hot hardness. This means that they are often used in applications that require a great deal of hardiness, such as in the aerospace and military fields.

[edit] Titanium alloys

Titanium alloys are made up of a mixture of titanium and other chemical elements. They are divided into grades which differentiate their properties and benefits such as formability and ductility.

This material tends to be lightweight even though other properties include extreme corrosion and heat resistance. Due to the hardwearing qualities of this material, it is often used in applications including aerospace, medical and automotive.

[edit] Copper alloys

Copper alloys are primarily composed of copper but have other metals added to create varying alloys with different properties and benefits. Bronze is the best-known copper alloy, and brass is another example.

These alloys have a high resistance to corrosion. Aluminium bronzes are particularly high in strength and corrosion resistance and can often be found in marine applications.

[edit] Super-alloys

Super-alloys benefit from the following characteristics:

- Excellent mechanical strength.

- Resistance to thermal creep deformation.

- Good surface stability.

- Resistance to corrosion or oxidation.

Due to these qualities, super-alloys are most commonly used in particularly high-stress applications, such as in the aerospace and marine sectors.

[edit] Related articles on Designing Buildings

- Bronze.

- Compression springs.

- E-Spring.

- Extension Springs.

- Flat springs.

- Key qualities of springs.

- Tension springs v torsion springs.

- The Importance of Gas Springs.

- Using springs in construction to prevent disaster.

--European Springs and Pressings Ltd 13:59, 16 Aug 2017 (BST)

Featured articles and news

Delayed, derailed and devalued

How the UK’s planning crisis is undermining British manufacturing.

How much does it cost to build a house?

A brief run down of key considerations from a London based practice.

The need for a National construction careers campaign

Highlighted by CIOB to cut unemployment, reduce skills gap and deliver on housing and infrastructure ambitions.

AI-Driven automation; reducing time, enhancing compliance

Sustainability; not just compliance but rethinking design, material selection, and the supply chains to support them.

Climate Resilience and Adaptation In the Built Environment

New CIOB Technical Information Sheet by Colin Booth, Professor of Smart and Sustainable Infrastructure.

Turning Enquiries into Profitable Construction Projects

Founder of Develop Coaching and author of Building Your Future; Greg Wilkes shares his insights.

IHBC Signpost: Poetry from concrete

Scotland’s fascinating historic concrete and brutalist architecture with the Engine Shed.

Demonstrating that apprenticeships work for business, people and Scotland’s economy.

Scottish parents prioritise construction and apprenticeships

CIOB data released for Scottish Apprenticeship Week shows construction as top potential career path.

From a Green to a White Paper and the proposal of a General Safety Requirement for construction products.

Creativity, conservation and craft at Barley Studio. Book review.

The challenge as PFI agreements come to an end

How construction deals with inherited assets built under long-term contracts.

Skills plan for engineering and building services

Comprehensive industry report highlights persistent skills challenges across the sector.

Choosing the right design team for a D&B Contract

An architect explains the nature and needs of working within this common procurement route.

Statement from the Interim Chief Construction Advisor

Thouria Istephan; Architect and inquiry panel member outlines ongoing work, priorities and next steps.

The 2025 draft NPPF in brief with indicative responses

Local verses National and suitable verses sustainable: Consultation open for just over one week.