Tension springs v torsion springs

Contents |

Introduction

Although sounding similar, tension and torsion springs are completely different. Tension springs are manufactured to operate with tension; as tightly wound coils, they stretch to a specific length as torque is applied to them. When in an unloaded position, the spring loops are touching with either a hook or a loop that is attached at one of the ends. The springs stretch when this attachment is directed with force. The springing action is caused when the components are pulled apart and the springs attempt to hold themselves together. After the force is stopped, they return to their original position.

Torsion springs are coiled springs, which work due to a twisting or torsion rotational motion. This allows for an object to store mechanical energy as it is twisted, exerting force in the opposite direction depending on the angle that it is twisted. A helical looped design is the most common design for torsion springs, which consists of a coiled metal wire that is twisted tighter and tighter by sideways forces that are applied on either a left-hand or a right-hand helix.

Tension Springs

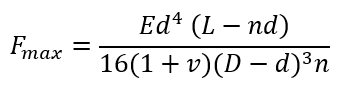

Most springs follow Hooke’s Law of elasticity, which states that the extension of an elastic rod is linearly proportional to the force, or torque, used to stretch it. The law is held approximately when the deformation is considered to be small in comparison to the overall length of the rod. The equation used to represent the force of a fully compressed spring is the following:

In which:

E – is Young’s modulus

d – is the spring wire diameter

L – is the free length of the spring

n – is the number of active windings

v – is Poisson’s ratio

D – is the spring’s outer diameter

Torsion Springs

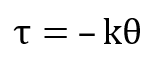

Torsion springs work by either twisting or torsion, in which they store mechanical energy when twisted. When they are twisted, the springs exert torque in the opposite direction in a proportional amount to the angle that they are twisted.

These springs obey Hooke’s Law, as long as not twisted beyond the elastic limit:

In which τ represents the exerted torque by the spring in newton-metres, k is a constant of newton-metres units, and θ represents the angle of twist from the equilibrium position in radians.

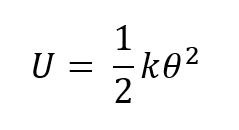

In joules, U, the energy stored in a torsion spring is represented by the following equation:

Uses of Tension Springs

Uses of Torsion Springs

--European Springs and Pressings Ltd 09:44, 25 Sep 2017 (BST)

Related articles on Designing Buildings Wiki

- Compression springs.

- E-spring.

- Flat springs.

- Key qualities of springs.

- Spring materials.

- The importance of gas springs.

- Using springs in construction to prevent disaster.

- The Difference Between Tension and Torsion Springs

- The Multiple Uses of Compression Springs

- The properties of tension springs.

- Using Springs in Construction to Prevent Disaster

- Torsion Springs and Their Benefits

Featured articles and news

The challenge as PFI agreements come to an end

How construction deals with inherit assets built under long-term contracts.

Skills plan for engineering and building services

Comprehensive industry report highlights persistent skills challenges across the sector.

Choosing the right design team for a D&B Contract

An architect explains the nature and needs of working within this common procurement route.

Statement from the Interim Chief Construction Advisor

Thouria Istephan; Architect and inquiry panel member outlines ongoing work, priorities and next steps.

The 2025 draft NPPF in brief with indicative responses

Local verses National and suitable verses sustainable: Consultation open for just over one week.

Increased vigilance on VAT Domestic Reverse Charge

HMRC bearing down with increasing force on construction consultant says.

Call for greater recognition of professional standards

Chartered bodies representing more than 1.5 million individuals have written to the UK Government.

Cutting carbon, cost and risk in estate management

Lessons from Cardiff Met’s “Halve the Half” initiative.

Inspiring the next generation to fulfil an electrified future

Technical Manager at ECA on the importance of engagement between industry and education.

Repairing historic stone and slate roofs

The need for a code of practice and technical advice note.

Environmental compliance; a checklist for 2026

Legislative changes, policy shifts, phased rollouts, and compliance updates to be aware of.

UKCW London to tackle sector’s most pressing issues

AI and skills development, ecology and the environment, policy and planning and more.

Managing building safety risks

Across an existing residential portfolio; a client's perspective.

ECA support for Gate Safe’s Safe School Gates Campaign.

Core construction skills explained

Preparing for a career in construction.

Retrofitting for resilience with the Leicester Resilience Hub

Community-serving facilities, enhanced as support and essential services for climate-related disruptions.