From Raw Materials to Aggregates, One Device Can Get It Done: Integrated Stone Crusher Analysis

The mining and aggregate production industry has witnessed significant advancements in equipment design and functionality over the years. One of the most notable innovations in recent times is the integrated stone crusher, which combines multiple stages of the crushing process into a single, streamlined device. This type of crusher offers exceptional benefits in terms of efficiency, cost-effectiveness, and space-saving, making it an attractive option for operators looking to optimise their production lines. In this article, we will explore the concept of integrated stone crushers, their advantages, and how they can enhance aggregate production operations.

Contents |

[edit] What is an Integrated Stone Crusher?

An integrated stone crusher plant is a versatile machine that combines several processes, such as primary, secondary, and sometimes even tertiary crushing, into a single unit. Traditionally, these processes would require separate pieces of equipment for each stage, leading to more complex setups, higher costs, and increased maintenance. By integrating all necessary functions into one machine, the integrated stone crusher simplifies the operation and reduces the need for additional equipment and space.

For example, a stone crusher plant may use an integrated unit that combines the jaw crusher, cone crusher, and sometimes even the screening process in one machine. This eliminates the need for separate machines to perform each stage of the operation, significantly improving workflow and reducing overhead costs.

[edit] Benefits of Using an Integrated Stone Crusher

[edit] 1. Cost-Effectiveness and Space-Saving

One of the most compelling reasons to choose an integrated stone crusher is its ability to save both space and money. Instead of purchasing and maintaining several separate machines, operators can rely on a single unit that performs multiple functions. This can greatly reduce both capital investment and operating costs.

In addition to the financial savings, the reduced need for multiple pieces of equipment allows for smaller operational footprints, which can be especially useful for operations with limited space. For example, if you are working in a tight quarry or urban area where space is a premium, opting for an integrated unit can be a smart solution. With a small type stone crusher operations can be carried out in smaller, more confined spaces, while still maintaining high productivity.

[edit] 2. Enhanced Efficiency and Reduced Downtime

The integration of several processes into one unit can dramatically improve the efficiency of the entire crushing operation. With a traditional setup, moving materials from one machine to another can result in bottlenecks, delays, and increased wear on equipment. By using an integrated stone crusher, material flows seamlessly through the crushing stages, minimising delays and ensuring that production is continuous and smooth.

Moreover, the reduced number of machines leads to fewer parts that can wear out, reducing the chances of breakdowns and extending the lifespan of the equipment. This means less downtime, fewer maintenance costs, and an overall increase in operational uptime.

[edit] 3. Versatility and Adaptability

An integrated stone crusher can be designed to handle a variety of materials and sizes, making it a versatile choice for different types of projects. Whether you're crushing limestone, granite, or other types of aggregates, these machines can be configured to meet specific material requirements. For instance, a limestone crusher integrated into a multi-stage unit can process large volumes of raw limestone rock and produce high-quality aggregates with ease.

The flexibility to process different materials in one unit also means that operators can quickly adjust to changing project requirements without having to invest in additional equipment. This adaptability makes the integrated stone crusher an attractive option for contractors working on diverse construction or mining projects.

[edit] Key Types of Integrated Stone Crushers

[edit] 1. Jaw-Cone Integrated Crushers

A popular configuration for stone crusher plants is the combination of a jaw crusher and a cone crusher. This integrated unit provides a robust and effective solution for both primary and secondary crushing. The jaw crusher performs the initial coarse crushing, breaking down larger stones into manageable sizes, while the cone crusher handles finer crushing, producing uniform aggregates.

This combination is ideal for operations dealing with a variety of materials, from soft aggregates to harder rocks like granite. It offers high efficiency and reduces the need for multiple crushers, leading to significant space and cost savings.

[edit] 2. Impact-Cone Integrated Crushers

Another integrated solution includes the combination of an impact crusher and a cone crusher. This setup is particularly effective for producing high-quality aggregates with consistent particle shapes. The impact crusher can break down the material into finer sizes, while the cone crusher ensures that the final product meets specific grading requirements. This combination is perfect for projects requiring a fine and uniform aggregate, especially for asphalt and concrete applications.

[edit] 3. Small Type Stone Crushers

For smaller-scale operations or tight sites, small type stone crushers provide an integrated solution that is compact, mobile, and efficient. These units are designed to handle smaller production volumes, making them perfect for contractors working on local road construction or small quarrying operations. Despite their smaller size, they still offer excellent crushing performance and can process a variety of materials, including limestone, sand, and gravel.

[edit] How to Choose the Right Integrated Stone Crusher

Selecting the right integrated stone crusher for your operation depends on several factors, including the type of material you are processing, the desired output size, and your budget. Here are some key considerations:

[edit] 1. Material Type and Hardness

If your operation involves crushing hard materials such as granite or basalt, you will need an integrated stone crusher with sufficient power and durability to handle the increased wear and tear. For softer materials like limestone, a limestone crusher may be more suitable.

[edit] 2. Production Capacity

The size and scale of your operation will also play a significant role in determining which type of integrated stone crusher to choose. Larger operations may benefit from a more robust and powerful integrated crusher capable of handling higher volumes of material.

[edit] 3. Space and Mobility Requirements

For operations with limited space or those requiring frequent relocation, a small type stone crusher or a mobile integrated crusher can provide the flexibility and portability needed for on-site crushing.

[edit] Conclusion

Integrated stone crushers are an excellent choice for modern aggregate production operations, offering numerous benefits such as cost savings, improved efficiency, and versatility. Whether you're dealing with limestone, granite, or other materials, these crushers can help streamline your processes and deliver high-quality aggregates with minimal downtime and maintenance. By carefully evaluating your project’s requirements, you can select the best integrated stone crusher for your operation, whether it’s a small, mobile unit or a larger, more powerful configuration.

Featured articles and news

Key points for construction at a glance with industry reactions.

Functionality, visibility and sustainability

The simpler approach to specification.

Architects, architecture, buildings, and inspiration in film

The close ties between makers and the movies, with our long list of suggested viewing.

SELECT three-point plan for action issued to MSPs

Call for Scottish regulation, green skills and recognition of electrotechnical industry as part of a manifesto for Scottish Parliamentary elections.

UCEM becomes the University of the Built Environment

Major milestone in its 106-year history, follows recent merger with London School of Architecture (LSE).

Professional practical experience for Architects in training

The long process to transform the nature of education and professional practical experience in the Architecture profession following recent reports.

A people-first approach to retrofit

Moving away from the destructive paradigm of fabric-first.

International Electrician Day, 10 June 2025

Celebrating the role of electrical engineers from André-Marie Amperè, today and for the future.

New guide for clients launched at Houses of Parliament

'There has never been a more important time for clients to step up and ...ask the right questions'

The impact of recycled slate tiles

Innovation across the decades.

EPC changes for existing buildings

Changes and their context as the new RdSAP methodology comes into use from 15 June.

Skills England publishes Sector skills needs assessments

Priority areas relating to the built environment highlighted and described in brief.

BSRIA HVAC Market Watch - May 2025 Edition

Heat Pump Market Outlook: Policy, Performance & Refrigerant Trends for 2025–2028.

Committing to EDI in construction with CIOB

Built Environment professional bodies deepen commitment to EDI with two new signatories: CIAT and CICES.

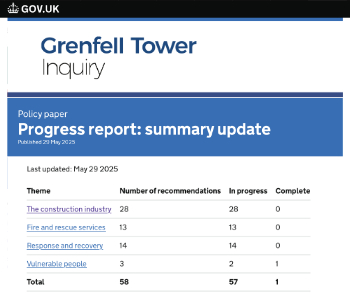

Government Grenfell progress report at a glance

Line by line recomendation overview, with links to more details.

An engaging and lively review of his professional life.

Sustainable heating for listed buildings

A problem that needs to be approached intelligently.

50th Golden anniversary ECA Edmundson apprentice award

Deadline for entries has been extended to Friday 27 June, so don't miss out!

CIAT at the London Festival of Architecture

Designing for Everyone: Breaking Barriers in Inclusive Architecture.

Mixed reactions to apprenticeship and skills reform 2025

A 'welcome shift' for some and a 'backwards step' for others.