Crushing machines

Contents |

[edit] Introduction

Coal crushers are generally employed in thermal power plants. There are various kinds that are available.

[edit] Mobile crushing plant

Mobile coal crushing plants have the advantage of mobility and low transportation cost. Compact design facilitates use in various sites, procedures and a wide range of materials without the need for groundwork. Moreover, mobile coal crushing station's have low energy consumption and simple installation.

[edit] Double roll coal crusher

A double roll coal crusher is designed to crush lumps of coal by breaking them into smaller pieces. This machine uses a massive cylinder that contains fins on both sides that raise coal lumps as it rotates. The device produces cubical coal, which is better for the environment. There is the option to place multiple units in series, these double roll crushers are self-driven and track-mounted.

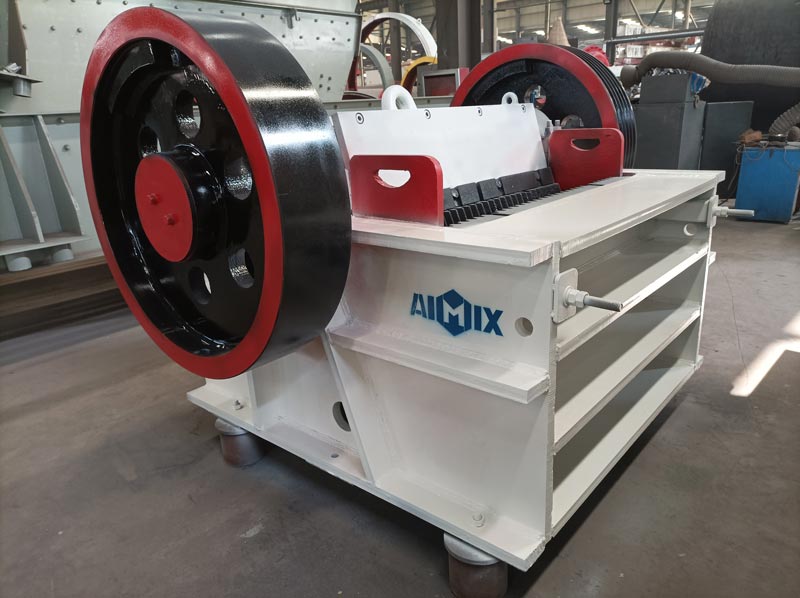

[edit] Jaw crusher

A jaw crusher is used to crush different hard materials into smaller pieces. The size of the crushed content from this machine is approximately five to twenty-five microns. Jaw crushers can process materials as diverse as coal, platinum ore, gold ore, copper, and so on. The smallest size depends on the material's hardness, toughness, and density. The size of the feed opening will also be impacted by the actual size of the jaw plates.

[edit] Gyratory crusher

A gyratory coal crusher is a primary crushing unit, so described as it has a tall crushing chamber, replaceable manganese wear plates, and adjustable main shaft positioning system. This unit is employed in a wide variety of applications, including primary and secondary crushing. Its crushing action is brought on by the closing of the gap involving the stationary concave liners as well as the mantle. The product will then be discharged from the bottom of the crusher.

[edit] Impact crusher

These crushers are mostly exported to Africa, Southeast Asia and the Middle East, in areas of rapid economic development. Infrastructure growth and mineral resources extraction has resulted in a strong market for large and small impact crushers.

[edit] Roll crusher

A roll crusher is a specialised coal crusher used for difficult brittle minerals. The theoretical maximum reduction ratio is 4:1, meaning a two-inch particle fed into the unit will be reduced to half an inch or smaller. Roll crushers have an adjustable spring and wedge device between the rollers, which stops the machine from shutting down because of overloading or iron passing within the crushing chamber.

[edit] Cone crusher

A cone crusher is a type of crushing machine that uses compression to produce a number of different particle sizes by adjusting the throw of the mantle, the spacing between the mantle as well as the concave shape. This gradation control is achieved by raising and lowering the top of the cone crusher, and this determines the way the final item is shaped. Some cone crushers let the operator regulate the mantle's throw, or how far it rotates off its axis.

[edit] Related articles on Designing Buildings

Featured articles and news

Delayed, derailed and devalued

How the UK’s planning crisis is undermining British manufacturing.

How much does it cost to build a house?

A brief run down of key considerations from a London based practice.

The need for a National construction careers campaign

Highlighted by CIOB to cut unemployment, reduce skills gap and deliver on housing and infrastructure ambitions.

AI-Driven automation; reducing time, enhancing compliance

Sustainability; not just compliance but rethinking design, material selection, and the supply chains to support them.

Climate Resilience and Adaptation In the Built Environment

New CIOB Technical Information Sheet by Colin Booth, Professor of Smart and Sustainable Infrastructure.

Turning Enquiries into Profitable Construction Projects

Founder of Develop Coaching and author of Building Your Future; Greg Wilkes shares his insights.

IHBC Signpost: Poetry from concrete

Scotland’s fascinating historic concrete and brutalist architecture with the Engine Shed.

Demonstrating that apprenticeships work for business, people and Scotland’s economy.

Scottish parents prioritise construction and apprenticeships

CIOB data released for Scottish Apprenticeship Week shows construction as top potential career path.

From a Green to a White Paper and the proposal of a General Safety Requirement for construction products.

Creativity, conservation and craft at Barley Studio. Book review.

The challenge as PFI agreements come to an end

How construction deals with inherited assets built under long-term contracts.

Skills plan for engineering and building services

Comprehensive industry report highlights persistent skills challenges across the sector.

Choosing the right design team for a D&B Contract

An architect explains the nature and needs of working within this common procurement route.

Statement from the Interim Chief Construction Advisor

Thouria Istephan; Architect and inquiry panel member outlines ongoing work, priorities and next steps.

The 2025 draft NPPF in brief with indicative responses

Local verses National and suitable verses sustainable: Consultation open for just over one week.