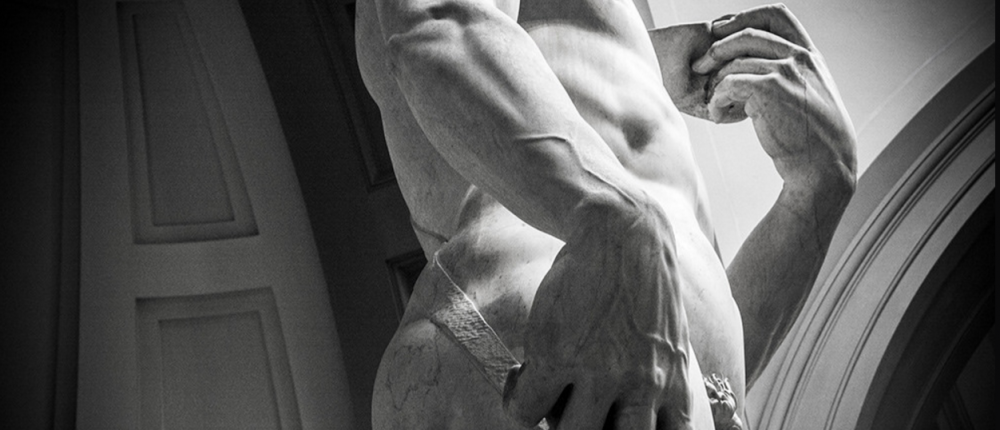

3D printing Michelangelo's David in concrete

It is perhaps the most staggering piece of artwork in the whole of human history, renowned for its accuracy in the depiction of the human body. Anyone who has seen it up close comes away in awe of the fact that someone had the ability to carve such a piece from stone.

Now, imagine, that one day we will see a 3D printer that could print Michelangelo’s David utilising concrete and other advanced materials – and that if such a statue would be placed next to the original, most people would be unable to tell the difference!

Science fiction? Not to me.

That was one of my messages in my March 2017 keynote for the American Concrete Institute, with with over 1,000 executives from this industry in the room.

My job was to outline for them the opportunities that will come to the industry from embracing fast paced trends. And I put on the table for them the idea that the boldest goal in their industry would be accomplished when someone was able to print Michelangelo’s David utilising a 3D printer.

It’s perhaps the equivalent of the well known Turing test, which is the ultimate challenge with computer technology — could a computer have the ability to exhibit intelligent behaviour equivalent to, or indistinguishable from, that of a human?

Farfetched? No. In fact, computer companies have been pursuing the goal of the Turing test in a feverish race.

This same thing will happen in the concrete industry with 3D printing — indeed, it’s a bold goal that some people are already thinking about in terms of the transformative trends sweeping the industry today.

Every industry has, or should have the equivalent of a Turing test. Think about robotics – how quickly will this industry mature? I toured a robotics display at a museum in Philadelphia, and one display suggested that there should be a 'Jetsons goal for robotics –the industry will have matured when it can build a robot that will be accepted by a family, just like Rosie the Robot from the popular 1960’s television cartoon.'

Here’s the thing — we might see these big bold bets be achieved sooner rather than later. I continually emphasise to my clients that the future is happening all around them, and that it’s happening faster than they think.

In China, an entire 4,305 sq. ft, 2-storey home has been printed with a 3D printer, with walls as thick as 8 ft and with 9 ft ceilings. It took 45 days from start to finish, and was printed in one go at the building site.

Consider this office building in Dubai which was printed in concrete using a 3D printer.

There are fascinating trends which come from the ability to 3D print with concrete. We can get more flexible designs, with concrete that is warped or twisted. Waste is significantly reduced, new design concepts are suddenly possible, and we can cut down on the cost of manufacturing.

People are talking about the fact that it will lead us to an era in which we can 'design for deconstruction' — printing in such a way that when a building is eventually decommissioned, we can dissassemble it rather than blowing it up!

Where is the world of construction headed? Consider this:

Your future home might be planned using virtual reality, built with a 3D printer and inspected by a robot for quality. What may sound like a sci-fi movie could become reality in a few decades as Singapore ramps up its construction productivity and employs more efficient building methods. Building with speed and quality through high-tech, Straits Times, Hong Kong, October 2016

Of course, 3D printing is already passe, I pointed out to my audience at the American Concrete Institute: people are already talking about 4D printing — which has materials that can change shape depending on the environment they are in!

Bottom line? Consider this comment by architect James Gardiner: “Using 3D-printed wax moulds for concrete components, we will have a completely different paradigm. This is transformative technology”.

What’s the Turing test or Michaelangelo’s David in your industry? And are you prepared to think in a big and bold way to get there before others do?

Written by Jim Carroll, futurist, trends & innovation expert, speaker.

Jim Carroll is a futurist, trends & innovation expert, with clients that range from NASA to Johnson and Johnson, the Swiss Innovation Forum to Whirlpool, speaking at approximately 50 events worldwide each year. He has an extensive blog at www.jimcarroll.com, and you can follow him on Twitter @jimcarroll

This article was originally published on the Future of Construction Knowledge Sharing Platform and the WEF Agenda Blog

[edit] Find out more

[edit] Related articles on Designing Buildings Wiki

- 3D printed bridge.

- 3D printing.

- Advanced construction technology.

- Cool brick.

- Printing 3D models of buildings.

- Shaping the Future of Construction: Inspiring innovators redefine the industry.

- XtreeE 3D concrete printing.

--Future of Construction 15:24, 20 Jun 2017 (BST)

Featured articles and news

A case study and a warning to would-be developers

Creating four dwellings for people to come home to... after half a century of doing this job, why, oh why, is it so difficult?

Reform of the fire engineering profession

Fire Engineers Advisory Panel: Authoritative Statement, reactions and next steps.

Restoration and renewal of the Palace of Westminster

A complex project of cultural significance from full decant to EMI, opportunities and a potential a way forward.

Apprenticeships and the responsibility we share

Perspectives from the CIOB President as National Apprentice Week comes to a close.

The first line of defence against rain, wind and snow.

Building Safety recap January, 2026

What we missed at the end of last year, and at the start of this...

National Apprenticeship Week 2026, 9-15 Feb

Shining a light on the positive impacts for businesses, their apprentices and the wider economy alike.

Applications and benefits of acoustic flooring

From commercial to retail.

From solid to sprung and ribbed to raised.

Strengthening industry collaboration in Hong Kong

Hong Kong Institute of Construction and The Chartered Institute of Building sign Memorandum of Understanding.

A detailed description from the experts at Cornish Lime.

IHBC planning for growth with corporate plan development

Grow with the Institute by volunteering and CP25 consultation.

Connecting ambition and action for designers and specifiers.

Electrical skills gap deepens as apprenticeship starts fall despite surging demand says ECA.

Built environment bodies deepen joint action on EDI

B.E.Inclusive initiative agree next phase of joint equity, diversity and inclusion (EDI) action plan.

Recognising culture as key to sustainable economic growth

Creative UK Provocation paper: Culture as Growth Infrastructure.

Futurebuild and UK Construction Week London Unite

Creating the UK’s Built Environment Super Event and over 25 other key partnerships.

Welsh and Scottish 2026 elections

Manifestos for the built environment for upcoming same May day elections.

Advancing BIM education with a competency framework

“We don’t need people who can just draw in 3D. We need people who can think in data.”