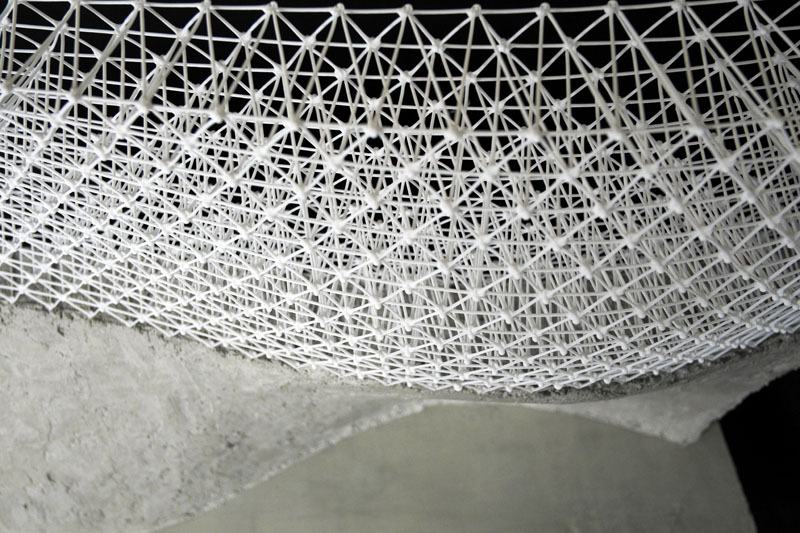

Mesh mould metal

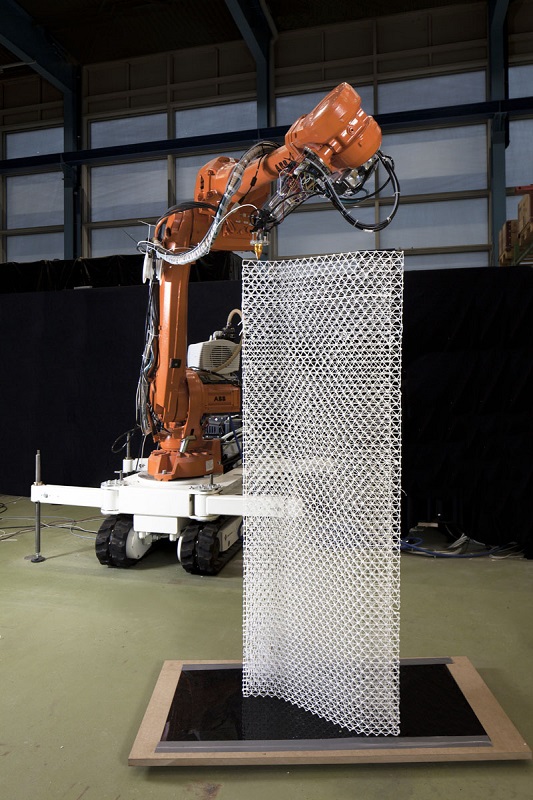

Since 2015, the Zurich-based research group Gramazio Kohler Research has been developing ‘mesh mould metal’. This is a project studying the unification of concrete reinforcement and formwork into a single, robotically-fabricated material system.

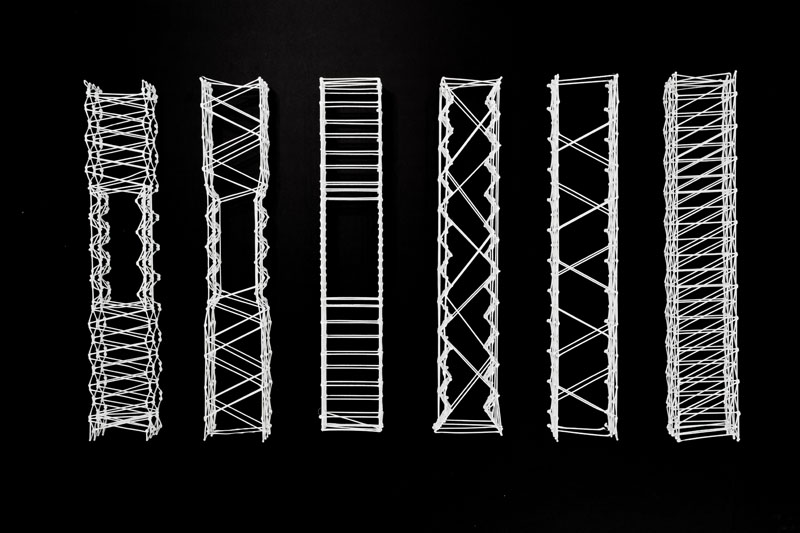

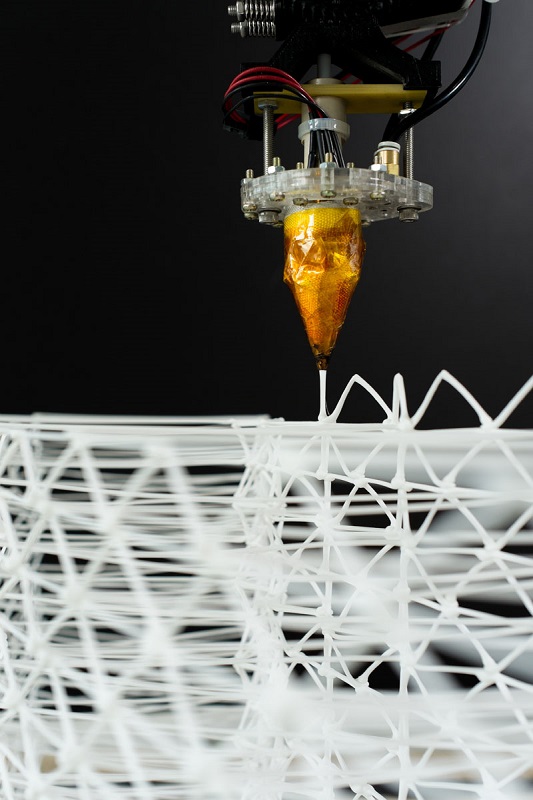

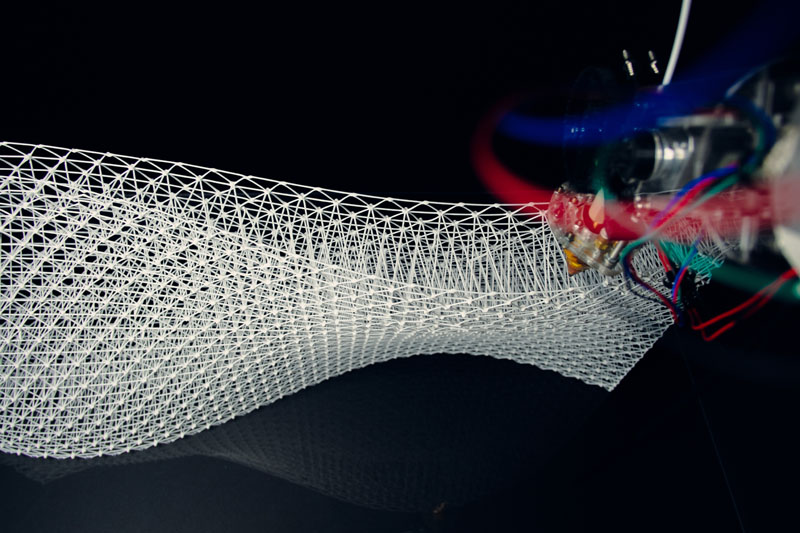

The first (2012-14) phase of research, ‘Mesh mould’, addressed the 1:1 construction aspects of robotically-fabricated load-bearing structures, and a robotic extrusion process for a polymer mesh.

The second phase, ‘Mesh mould metal’, has focused on the transition of the structurally-weak polymer-based extrusion process into a fully load-bearing construction system, by replicating the process in metal.

The research involves the development of ‘a fully automated bending and welding process for meshes fabricated from 3 mm steel wire.’

Standard industrial robots have limited payload capacities yet have a high capacity for precise spatial coordination. Therefore, their optimal use requires construction processes with minimal mass transfer and a high degree of geometric definition. Subsequently, the focus of the investigation was fabrication with material efficiency in mind, with geometrically complex concrete elements.

The project was conducted in collaboration with Sika Technology AG. Mesh Mould is also embedded into the National Competence Centre in Research (NCCR) Digital Fabrication, and funded by the Swiss National Science Foundation.

Images copyright Gramazio Kohler Research, ETH Zurich.

Content and images courtesy of GKR. For more information, see GKR.

[edit] Related articles on Designing Buildings Wiki

Featured articles and news

International Electrician Day, 10 June 2025

Celebrating the role of electrical engineers from André-Marie Amperè, today and for the future.

New guide for clients launched at Houses of Parliament

'There has never been a more important time for clients to step up and ...ask the right questions'

The impact of recycled slate tiles

Innovation across the decades.

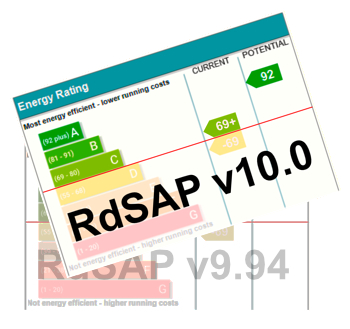

EPC changes for existing buildings

Changes and their context as the new RdSAP methodology comes into use from 15 June.

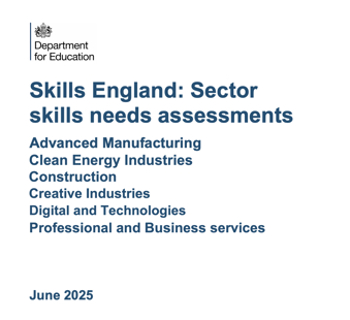

Skills England publishes Sector skills needs assessments

Priority areas relating to the built environment highlighted and described in brief.

BSRIA HVAC Market Watch - May 2025 Edition

Heat Pump Market Outlook: Policy, Performance & Refrigerant Trends for 2025–2028.

Committing to EDI in construction with CIOB

Built Environment professional bodies deepen commitment to EDI with two new signatories: CIAT and CICES.

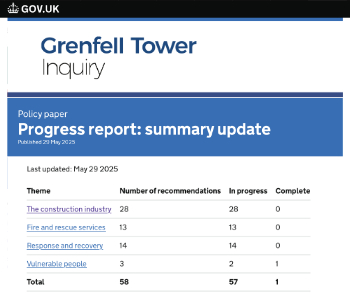

Government Grenfell progress report at a glance

Line by line recomendation overview, with links to more details.

An engaging and lively review of his professional life.

Sustainable heating for listed buildings

A problem that needs to be approached intelligently.

50th Golden anniversary ECA Edmundson apprentice award

Deadline for entries has been extended to Friday 27 June, so don't miss out!

CIAT at the London Festival of Architecture

Designing for Everyone: Breaking Barriers in Inclusive Architecture.

Mixed reactions to apprenticeship and skills reform 2025

A 'welcome shift' for some and a 'backwards step' for others.

Licensing construction in the UK

As the latest report and proposal to licence builders reaches Parliament.

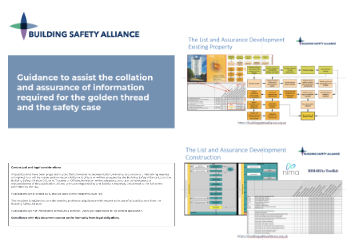

Building Safety Alliance golden thread guidance

Extensive excel checklist of information with guidance document freely accessible.

Fair Payment Code and other payment initiatives

For fair and late payments, need to work together to add value.

Pre-planning delivery programmes and delay penalties

Proposed for housebuilders in government reform: Speeding Up Build Out.

High street health: converting a building for healthcare uses

The benefits of health centres acting as new anchor sites in the high street.