Mesh mould metal

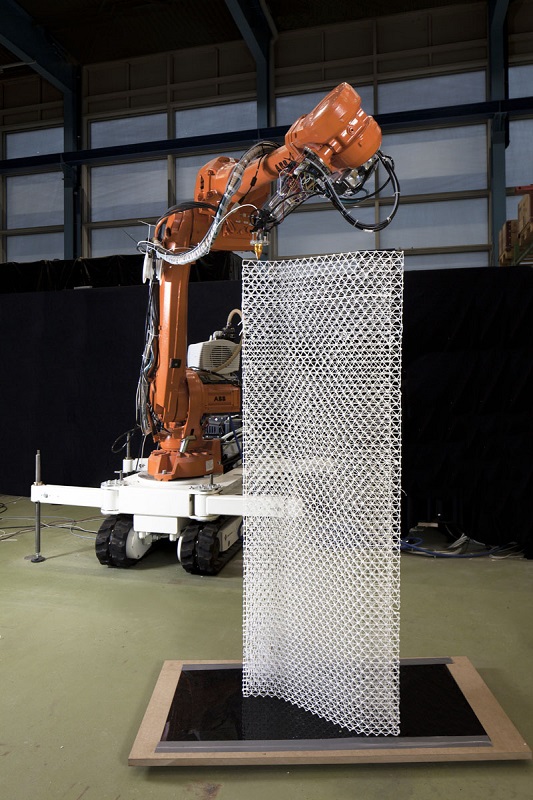

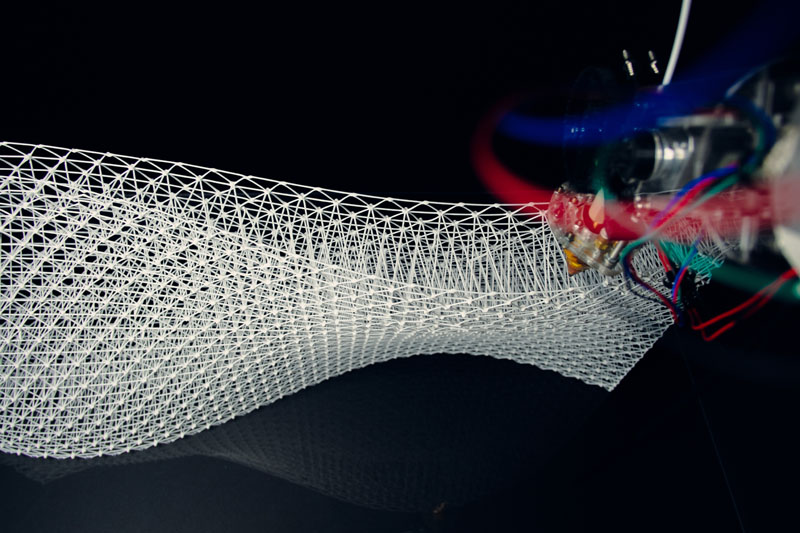

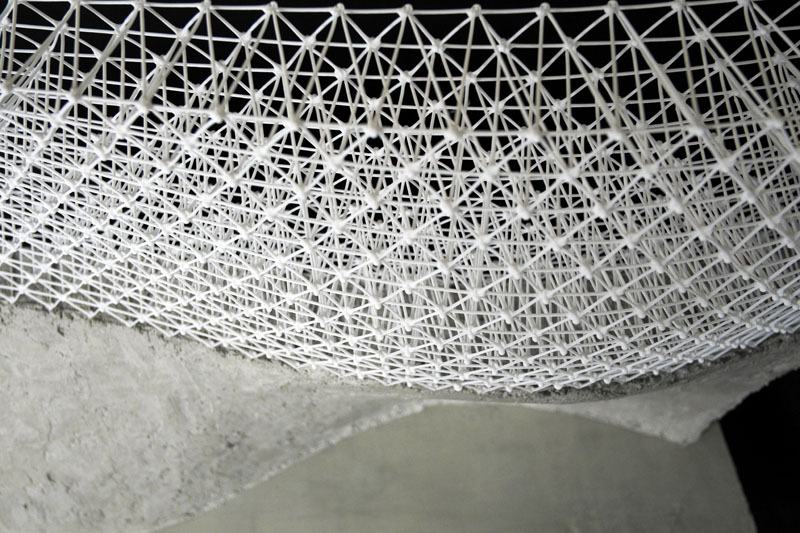

Since 2015, the Zurich-based research group Gramazio Kohler Research has been developing ‘mesh mould metal’. This is a project studying the unification of concrete reinforcement and formwork into a single, robotically-fabricated material system.

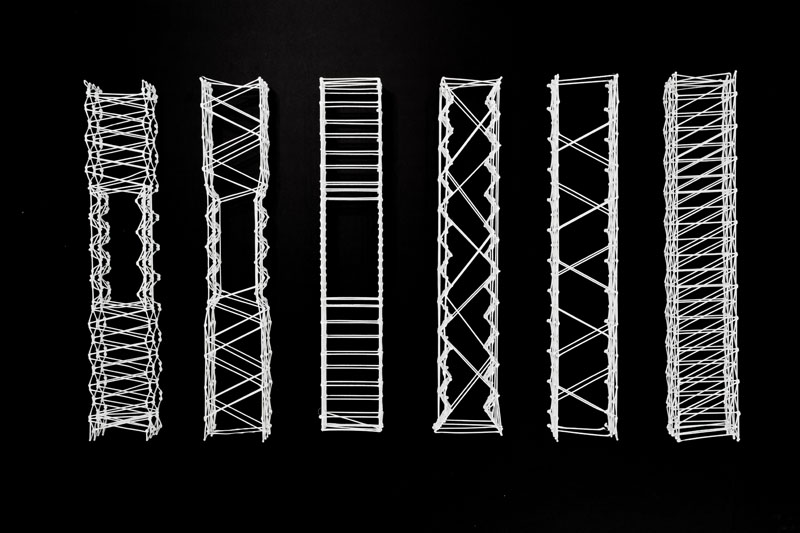

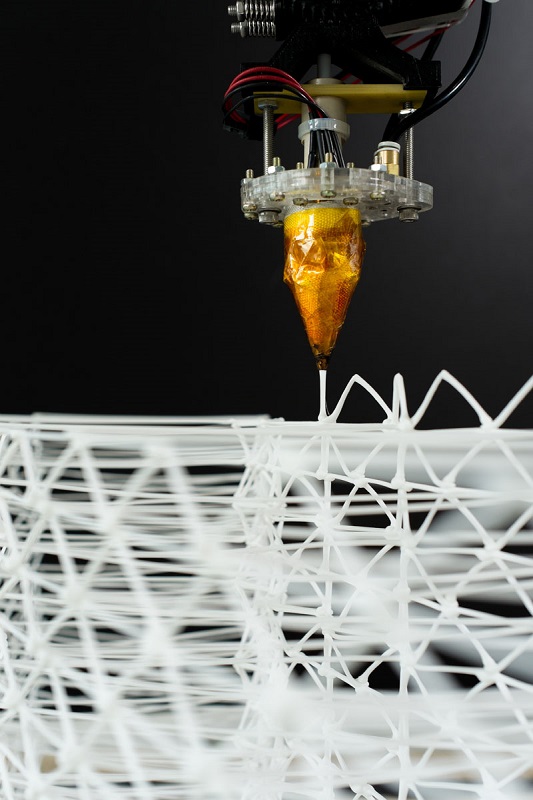

The first (2012-14) phase of research, ‘Mesh mould’, addressed the 1:1 construction aspects of robotically-fabricated load-bearing structures, and a robotic extrusion process for a polymer mesh.

The second phase, ‘Mesh mould metal’, has focused on the transition of the structurally-weak polymer-based extrusion process into a fully load-bearing construction system, by replicating the process in metal.

The research involves the development of ‘a fully automated bending and welding process for meshes fabricated from 3 mm steel wire.’

Standard industrial robots have limited payload capacities yet have a high capacity for precise spatial coordination. Therefore, their optimal use requires construction processes with minimal mass transfer and a high degree of geometric definition. Subsequently, the focus of the investigation was fabrication with material efficiency in mind, with geometrically complex concrete elements.

The project was conducted in collaboration with Sika Technology AG. Mesh Mould is also embedded into the National Competence Centre in Research (NCCR) Digital Fabrication, and funded by the Swiss National Science Foundation.

Images copyright Gramazio Kohler Research, ETH Zurich.

Content and images courtesy of GKR. For more information, see GKR.

[edit] Related articles on Designing Buildings Wiki

Featured articles and news

Reform of the fire engineering profession

Fire Engineers Advisory Panel: Authoritative Statement, reactions and next steps.

Restoration and renewal of the Palace of Westminster

A complex project of cultural significance from full decant to EMI, opportunities and a potential a way forward.

Apprenticeships and the responsibility we share

Perspectives from the CIOB President as National Apprentice Week comes to a close.

The first line of defence against rain, wind and snow.

Building Safety recap January, 2026

What we missed at the end of last year, and at the start of this...

National Apprenticeship Week 2026, 9-15 Feb

Shining a light on the positive impacts for businesses, their apprentices and the wider economy alike.

Applications and benefits of acoustic flooring

From commercial to retail.

From solid to sprung and ribbed to raised.

Strengthening industry collaboration in Hong Kong

Hong Kong Institute of Construction and The Chartered Institute of Building sign Memorandum of Understanding.

A detailed description from the experts at Cornish Lime.

IHBC planning for growth with corporate plan development

Grow with the Institute by volunteering and CP25 consultation.

Connecting ambition and action for designers and specifiers.

Electrical skills gap deepens as apprenticeship starts fall despite surging demand says ECA.

Built environment bodies deepen joint action on EDI

B.E.Inclusive initiative agree next phase of joint equity, diversity and inclusion (EDI) action plan.

Recognising culture as key to sustainable economic growth

Creative UK Provocation paper: Culture as Growth Infrastructure.

Futurebuild and UK Construction Week London Unite

Creating the UK’s Built Environment Super Event and over 25 other key partnerships.

Welsh and Scottish 2026 elections

Manifestos for the built environment for upcoming same May day elections.

Advancing BIM education with a competency framework

“We don’t need people who can just draw in 3D. We need people who can think in data.”