The use of rubber expansion joints in lead guttering

[edit] Lead guttering: A flexible approach

A question that is often asked of professionals is about the correct way to fit a lead gutter. Should they be fitted in the traditional way with drips (steps) breaking up the lengths or can rubber expansion joints be used?

[Example of a typical box gutter]

One answer is that if it can be done the traditional way then it should be. However, if the situation means this can’t be done, there may be no choice other than to use an alternative method.

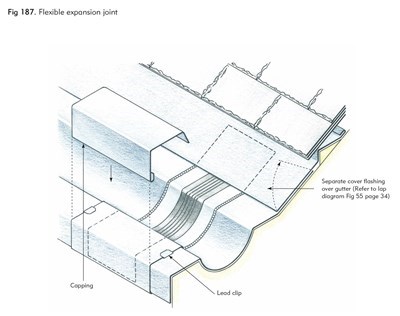

So what is a rubber expansion joint and when should it be used?

To a certain extent, the answer lies in its history. Neoprene expansion joints, to give them their proper name, were first used in Europe in conjunction with zinc and copper gutter linings. The idea being that a method of jointing was needed to take into account the thermal expansion of certain types of metals. Traditional methods for jointing copper gutters, again with steps along its length, could not be easily replicated in zinc as the material is not as malleable.

In the early-1990s, the same principle was introduced to leadwork. The reason for this was that traditional wall head gutters that were made from concrete and lined with lead, which can be found on many older buildings, needed the leadwork replaced.

Traditionally, the lead lining pieces were just lapped and water ingress was inevitable. As it was impossible to create the traditional steps in these installations, neoprene expansion joints were seen as a good solution.

Over the years, these types of joints have been applied in many different gutter situations and appear to be giving a good service life to date. Their popularity has grown given that they can be welded into place much faster than using traditional ‘bossing’ methods to form the drips.

[edit] Why is that a problem?

One of the main reasons that we refer to these as a ‘last resort’ is that they only carry a manufacturers guarantee of 5 - 10 years. Lead on the other hand is expected to give a service life in excess of 60 - 100 years.

Having a component within this that may have a shorter lifespan is an obvious weak point and one that should be avoided if possible. Their use should be restricted to places where there is no choice, as it may restrict any insurance backed guarantees and could, in certain circumstances, lead to costly replacement works which would require full scaffold access.

All leadworks should take into account the anticipated life of the building concerned. Where a shorter service life may be acceptable to a building owner or developer the use of neoprene expansion joints could be considered. By contrast, where maximum service life is required standard traditional details should always be used. If neoprene joints are proposed, this should be discussed with the client and built into any maintenance programme.

All the details used here are from the LSA's Complete Manual, which includes a wealth of detail on installation and specification. Further information and technical support is available at www.leadsheet.co.uk.

This article was written by Darren Tutt, Senior Technical Officer, The Lead Sheet Association

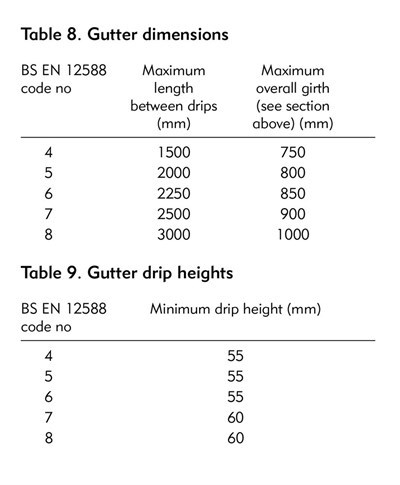

NB: Any detailing provided by the Lead Sheet Association refers to the use of Rolled Lead Sheet to BS EN 12588.

[edit] Related articles on Designing Buildings Wiki

Featured articles and news

Inspiring the next generation to fulfil an electrified future

Technical Manager at ECA on the importance of engagement between industry and education.

Repairing historic stone and slate roofs

The need for a code of practice and technical advice note.

Environmental compliance; a checklist for 2026

Legislative changes, policy shifts, phased rollouts, and compliance updates to be aware of.

UKCW London to tackle sector’s most pressing issues

AI and skills development, ecology and the environment, policy and planning and more.

Managing building safety risks

Across an existing residential portfolio; a client's perspective.

ECA support for Gate Safe’s Safe School Gates Campaign.

Core construction skills explained

Preparing for a career in construction.

Retrofitting for resilience with the Leicester Resilience Hub

Community-serving facilities, enhanced as support and essential services for climate-related disruptions.

Some of the articles relating to water, here to browse. Any missing?

Recognisable Gothic characters, designed to dramatically spout water away from buildings.

A case study and a warning to would-be developers

Creating four dwellings... after half a century of doing this job, why, oh why, is it so difficult?

Reform of the fire engineering profession

Fire Engineers Advisory Panel: Authoritative Statement, reactions and next steps.

Restoration and renewal of the Palace of Westminster

A complex project of cultural significance from full decant to EMI, opportunities and a potential a way forward.

Apprenticeships and the responsibility we share

Perspectives from the CIOB President as National Apprentice Week comes to a close.

The first line of defence against rain, wind and snow.

Building Safety recap January, 2026

What we missed at the end of last year, and at the start of this.