Road joints

Contents |

[edit] Introduction

Joints are formed in concrete slabs as part of the process of constructing rigid paving for roads. Joints are discontinuities in the pavement slab that are necessary to allow for expansion, contraction and warping. Rigid paving consists of a reinforced or unreinforced insitu concrete slab laid over a thin granular base course. The rigidity and strength of the pavement enables the loads and stresses to be distributed over a wide area of the subgrade.

Joints are spaced depending on a range of factors:

- The amount of reinforcement used.

- The proposed traffic intensity.

- The slab thickness.

- The frictional restraint of the subgrade.

- The temperature at which the concrete is laid.

Joints comprise a filler which separates the slabs, and a sealing compound which is used to fill the top 25 mm of the joint to prevent the entry of water and grit. Suitable jointing materials include impregnated fibre board, cork, sheet bitumen, and rubber. The joint sealing compound must have good adhesion to concrete, extensibility without fracture, resistance to flow in hot weather, and durability.

A system of dowel bars in introduced between slabs to prevent slab movement and ensure load-transfer. Dowel bars are positioned at mid-depth of the slab at centres of 300 mm. The diameter of the bar usually ranges from 20-30 mm but varies with the slab thickness. A plastic sleeve 100 mm-long is inserted on one end of the dowel to allow free movement of the slab. The sleeve should contain a pad of compressible material at the end.

[edit] Types of road joints

There are a number of different types of joints:

[edit] Expansion joint

These are provided along the transverse direction to allow the expansion and contraction of a concrete slab due to temperature and subgrade moisture variation. They are intended to prevent potentially damaging forces accumulating within the slab itself or surrounding structures. Maximum spacing of expansion joints range from 25-27 m in jointed reinforced concrete slabs, and from 40 m (for slabs <230 mm thick) to 60 m (for slabs >230 mm thick) in unreinforced concrete.

[edit] Contraction joint

These are also known as ‘shrinkage’ joints and are provided along the transverse direction to allow for contraction or shrinkage of the slab during the curing process. Maximum spacing of contraction joints ranges from 12-24 m in reinforced slabs, and from 4-5 m in unreinforced slabs.

[edit] Construction joint

Construction joints are provided whenever the construction work stops temporarily. They can be either along the transverse or longitudinal direction.

[edit] Warping joint

Warping joints are provided along the longitudinal direction to prevent warping of the concrete slab due to temperature and subgrade moisture variation.

[edit] Related articles on Designing Buildings

- Bituminous mixing and laying plant.

- Code of Practice for Ironwork Systems Installation and Refurbishment.

- Highway drainage.

- Joint v connection.

- Kerbs.

- Overview of the road development process.

- Pavement.

- Road construction.

- Runway construction.

- Settlement.

- Types of road and street.

[edit] External references

- ‘Introduction to civil engineering construction’ (3rd ed.), HOLMES, R., The College of Estate Management (1995)

Featured articles and news

Latest Build UK Building Safety Regime explainer published

Key elements in one short, now updated document.

UKGBC launch the UK Climate Resilience Roadmap

First guidance of its kind on direct climate impacts for the built environment and how it can adapt.

CLC Health, Safety and Wellbeing Strategy 2025

Launched by the Minister for Industry to look at fatalities on site, improving mental health and other issues.

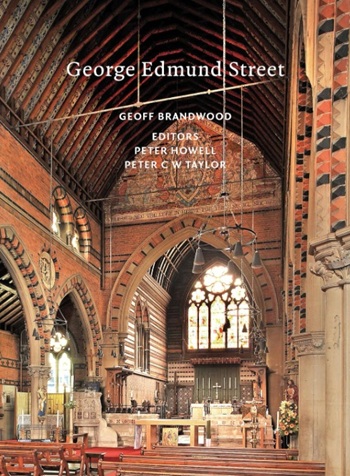

One of the most impressive Victorian architects. Book review.

Common Assessment Standard now with building safety

New CAS update now includes mandatory building safety questions.

RTPI leader to become new CIOB Chief Executive Officer

Dr Victoria Hills MRTPI, FICE to take over after Caroline Gumble’s departure.

Social and affordable housing, a long term plan for delivery

The “Delivering a Decade of Renewal for Social and Affordable Housing” strategy sets out future path.

A change to adoptive architecture

Effects of global weather warming on architectural detailing, material choice and human interaction.

The proposed publicly owned and backed subsidiary of Homes England, to facilitate new homes.

How big is the problem and what can we do to mitigate the effects?

Overheating guidance and tools for building designers

A number of cool guides to help with the heat.

The UK's Modern Industrial Strategy: A 10 year plan

Previous consultation criticism, current key elements and general support with some persisting reservations.

Building Safety Regulator reforms

New roles, new staff and a new fast track service pave the way for a single construction regulator.

Architectural Technologist CPDs and Communications

CIAT CPD… and how you can do it!

Cooling centres and cool spaces

Managing extreme heat in cities by directing the public to places for heat stress relief and water sources.

Winter gardens: A brief history and warm variations

Extending the season with glass in different forms and terms.

Restoring Great Yarmouth's Winter Gardens

Transforming one of the least sustainable constructions imaginable.