Last Planner System

Contents |

[edit] Introduction

The Last Planner System (LPS) is a collaborative planning process that involves trade foremen or design team leaders (the last planners) in planning in greater and greater detail as the time for the work to be done gets closer. In the UK it is sometimes known as Collaborative Planning and, in the USA, sometimes called Pull Planning.

LPS was created to enable more reliable and predictable production in projects. It also:

- supports the flow of work through the project

- builds trust and collaboration with a project team

- delivers safer projects faster.

LPS brings together those who will execute the work (the team) to plan when and how work will be done through a series of conversational processes. It requires the team to collaboratively remove constraints as a team and to promise delivery of each task. These systematic processes increase the chances that work flows reliably, and recognises that personal relationships and peer pressure are critical to that process.

LPS is a planning, monitoring and control system that follows lean construction principles. It was developed by Glenn Ballard and Greg Howell who later founded the Lean Construction Institute at the behest of a number of constructors who had benefited from their use of LPS.

[edit] Five key processes

Each process (or conversation) within the system brings its own benefits. When all are working together they reinforce each other and the overall benefits are greater. The processes are:

- Collaborative Programming [1] - Creating and agreeing the production sequence (and compressing it if required) and agreeing the key hand-overs from one trade or design team to the next.

- Make Ready [2] - Making tasks in the Look Ahead period ready (i.e. constraint free) so that they can be done when the team want to do them.

- Production Planning - Collaboratively agreeing production tasks for the next period (e.g. shift, day or week) – this is often referred to as Weekly Work Planning (WWP).

- Production Management - Collaboratively monitoring production to keep activities on track, generally on a daily basis.

- Measurement, learning and continual improvement - Learning and improving project, planning and production processes so as to improve the flow and the rate of flow of the work.

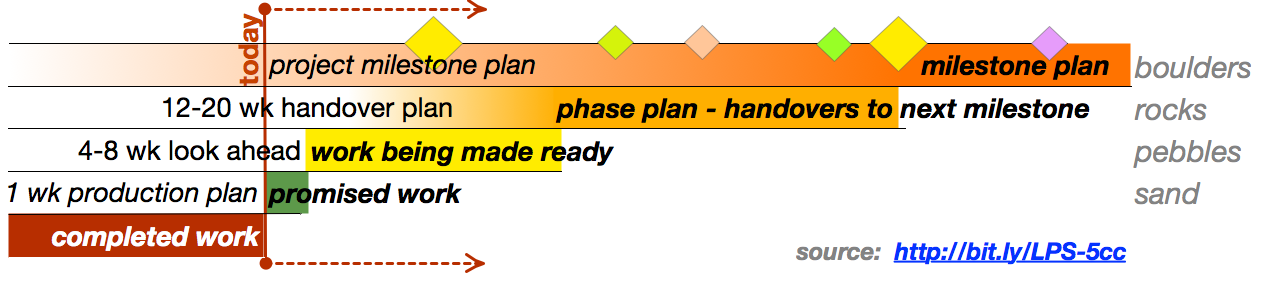

Figure 1: In the Last Planner System the level of plan detail increases as the day for the work to be done approaches (source: Mossman 2015 with permission)

[edit] Measurement & learning

The Last Planner System has a number of measures:

- Percent Plan (or Promises) Complete (often referred to as PPC, a measure of plan reliability).

- Tasks made ready (a measure of the effectiveness of the Make Ready Process).

- Tasks anticipated (a measure of the ability of the team to anticipate the work they need to plan).

The metrics are calculated for the project as a whole. The reason for using these metrics is to learn. If the metrics are used for any other purpose than as an aid to learning and improvement their value as a learning aid diminishes as those involved start to 'game the system'.

When tasks are not completed as promised the 5Why process can be used to find the root cause of the late or early delivery and then countermeasures developed to reduce the chances that the problem will happen again. In this way learning this week is built into operations next week.

[edit] Last Planner principles

- All plans are forecasts; all forecasts are wrong.

- The longer the forecast, the more wrong it gets.

- The more detailed the forecast, the wronger it is (first formulated by Ballard ca. 1991).

The implication of these principles are that it is important to (Ballard et al 2009):

- Plan in greater detail as you get closer to doing the work.

- Produce plans collaboratively with those who will do the work.

- Reveal and remove constraints on planned tasks as a team.

- Make and secure reliable promises.

- Learn from breakdowns.

In addition, it is important to:

- Measure promises kept (see above) and improve by learning from early, late or incomplete deliveries and workflow disruptions.

- Improve workflow as a team based on what has been learned.

[edit] Find out more

[edit] Related articles on Designing Buildings Wiki

[edit] External references

- Lean Construction Institute

- Ballard Glenn & Gregory A. Howell (1998) Shielding Production: An Essential Step in Production Control. J Constr Eng & Proj Mgmt, 124(1) 11–17. [this is an important paper and still very relevant.]

- Ballard, Glenn (2000). Last Planner™ System of Production Control (pdf) (Ph.D.). UK: University of Birmingham. [note: LPS has moved on in the 15 years since Ballard completed his thesis – both theory and practice have developed since then.]

- Ballard Glenn & Gregory A. Howell (2003) An update on Last Planner. IGLC

- Ballard, G. , Hammond, J. & Nickerson, R. (2009) Production Control Principles IGLC

- Gregory Howell and Hal Macomber (2011) The Last Planner System: Conversations that Design and Activate the Network of Commitments LPC

- Ballard, Glenn (2014) The Last Planner System of Production Planning & Control Norway ppt.pdf

- Mossman, Alan (2015) Last Planner®: 5 + 1 crucial & collaborative conversations for predictable design & construction delivery. 36pp

- LPC (2011) Last Planner System - Just the Essentials

- Macomber Bettler (2011) Responsibility-based Project Delivery [LPC] — an agile adaptation of LPS for use in design

- Andrew Baldwin David Bordoli 2014 Handbook for Construction Planning and Scheduling App2 362-366 The Shepherd Way and Collaborative Planning [Note that this version of LPS, like many that use the terms Collaborative Planning or Pull Planning, is only a partial implementation of Last Planner. The make ready process (called 'forward planning') did not bring the whole team together and there was no explicit learning process built in. Despite this the benefits for Shepherd were significant.

[1] sometimes called pull scheduling, pull planning, reverse phase scheduling, collaborative planning, collaborative mapping, sticky-note planning

[2] sometimes called LookAhead planning [all plans look ahead!]

Featured articles and news

A case study and a warning to would-be developers

Creating four dwellings for people to come home to... after half a century of doing this job, why, oh why, is it so difficult?

Reform of the fire engineering profession

Fire Engineers Advisory Panel: Authoritative Statement, reactions and next steps.

Restoration and renewal of the Palace of Westminster

A complex project of cultural significance from full decant to EMI, opportunities and a potential a way forward.

Apprenticeships and the responsibility we share

Perspectives from the CIOB President as National Apprentice Week comes to a close.

The first line of defence against rain, wind and snow.

Building Safety recap January, 2026

What we missed at the end of last year, and at the start of this...

National Apprenticeship Week 2026, 9-15 Feb

Shining a light on the positive impacts for businesses, their apprentices and the wider economy alike.

Applications and benefits of acoustic flooring

From commercial to retail.

From solid to sprung and ribbed to raised.

Strengthening industry collaboration in Hong Kong

Hong Kong Institute of Construction and The Chartered Institute of Building sign Memorandum of Understanding.

A detailed description from the experts at Cornish Lime.

IHBC planning for growth with corporate plan development

Grow with the Institute by volunteering and CP25 consultation.

Connecting ambition and action for designers and specifiers.

Electrical skills gap deepens as apprenticeship starts fall despite surging demand says ECA.

Built environment bodies deepen joint action on EDI

B.E.Inclusive initiative agree next phase of joint equity, diversity and inclusion (EDI) action plan.

Recognising culture as key to sustainable economic growth

Creative UK Provocation paper: Culture as Growth Infrastructure.

Futurebuild and UK Construction Week London Unite

Creating the UK’s Built Environment Super Event and over 25 other key partnerships.

Welsh and Scottish 2026 elections

Manifestos for the built environment for upcoming same May day elections.

Advancing BIM education with a competency framework

“We don’t need people who can just draw in 3D. We need people who can think in data.”