Polished plaster

Contents |

[edit] Introduction

Plaster is a building material used for coating, protecting and decorating internal walls and ceilings. It can also be used to create architectural mouldings such as ceiling roses, cornices, corbels, and so on.

A wide range of decorative finishes may be grouped under the term ‘polished plaster’. They are characterised by mimicking decorative stone finishes such as polished marble or deeply-textured effects such as limestone or travertine. As polished plaster appears to be something it is not, it can be described as an illusion, giving a highly-realistic impression of texture and depth that has been prized and applied to great effect since ancient times.

[edit] Composition and application

Polished plaster is made from slaked lime, marble dust and /or marble chips – the exact ratio depending on the final effect required. Up to 40% of the final mix may be marble powder. Natural earth or synthetic pigments may also be added to provide special colour effects.

Polished plaster is typically applied to internal walls, ceilings and columns. A primer is first applied to the substrate followed by up to four layers of basecoat. A steel trowel is used to burnish (finish) the plaster to a glass-smooth effect; a protective wax may be applied to seal the finish.

Typical applications include hotels, public buildings, galleries, bars and restaurants. It has also become popular for luxury bathrooms and other wet areas due to its smooth, waterproof and anti-bacterial properties.

The final appearance depends on the material composition, the effects used and particularly the skill of the plasterer, who may be able to create effects ranging from plain, light polished surfaces to more highly burred and marble-type effects.

However, damage to polished paster can be difficult to repair.

[edit] Historical usage

The use of polished plaster goes back to the ancient Egyptians. It was also used by the Greeks and the Romans. The Roman military architect and engineer Vitruvius (c.90BC – c.20BC) extolled the virtues of polished plasters in his Ten Books on Architecture.

The next period of popularity came during the Italian Renaissance in Northern Italy when it was called ’marmorino’, short for marmorino veneziano (venetian polished plaster). It was used extensively both internally and externally, particularly as a background for ornate frescoes. Colour came from natural pigments but, due to their inconsistencies and variable strengths, required the expert manipulation of professional colourists. This was one reason it became a finish that was the preserve of the rich.

Another Venetian variant, stucco lustro, comprised a base of 2-3 layers of semi-dry marmorino followed by up to 10-15 fine coats of stucco. It was finished to a mirror-like effect using hot irons.

In 17th and 18th century Britain, the use of polished plaster on walls and columns for reasons of aesthetics, economy and practicality gave a highly-realistic impression of marble or travertine, creating an illusion of depth and texture, without requiring the stonemason’s craft – and at a fraction of the cost.

Today, not unlike the historical precedents, polished plaster finishes are undergoing a revival of interest and tend to lie at the upper end of the price range due to the labour input that is required.

[edit] Related articles on Designing Buildings

Featured articles and news

Government consultations for the summer of 2025

A year of Labour, past and present consultations on the environment, the built environment, training and tax.

CMA competitiveness probe of major housing developers

100 million affordable housing contributions committed with further consultation published.

Homes England supports Greencore Homes

42 new build affordable sustainable homes in Oxfordshire.

Zero carbon social housing: unlocking brownfield potential

Seven ZEDpod strategies for brownfield housing success.

CIOB report; a blueprint for SDGs and the built environment

Pairing the Sustainable Development Goals with projects.

Types, tests, standards and fires relating to external cladding

Brief descriptions with an extensive list of fires for review.

Latest Build UK Building Safety Regime explainer published

Key elements in one short, now updated document.

UKGBC launch the UK Climate Resilience Roadmap

First guidance of its kind on direct climate impacts for the built environment and how it can adapt.

CLC Health, Safety and Wellbeing Strategy 2025

Launched by the Minister for Industry to look at fatalities on site, improving mental health and other issues.

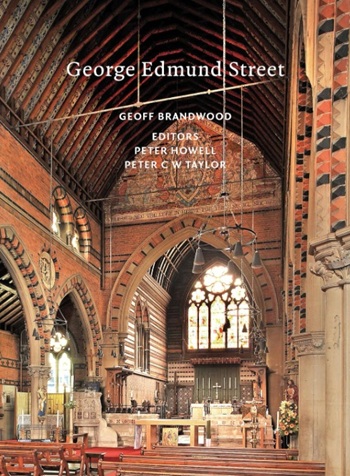

One of the most impressive Victorian architects. Book review.

Common Assessment Standard now with building safety

New CAS update now includes mandatory building safety questions.

RTPI leader to become new CIOB Chief Executive Officer

Dr Victoria Hills MRTPI, FICE to take over after Caroline Gumble’s departure.

Social and affordable housing, a long term plan for delivery

The “Delivering a Decade of Renewal for Social and Affordable Housing” strategy sets out future path.

A change to adoptive architecture

Effects of global weather warming on architectural detailing, material choice and human interaction.

The proposed publicly owned and backed subsidiary of Homes England, to facilitate new homes.

How big is the problem and what can we do to mitigate the effects?

Overheating guidance and tools for building designers

A number of cool guides to help with the heat.

The UK's Modern Industrial Strategy: A 10 year plan

Previous consultation criticism, current key elements and general support with some persisting reservations.

Building Safety Regulator reforms

New roles, new staff and a new fast track service pave the way for a single construction regulator.