File:WhatsApp Image 2024-11-01 at 11.24.26.jpeg

Contents |

[edit] How Continox Built This Stunning Staircase

[edit] Introduction

At Continox, we pride ourselves on delivering bespoke staircase designs that blend functionality and aesthetics. This staircase is a prime example of our craftsmanship and engineering excellence. Here’s an in-depth look at how we brought this project to life, from initial planning to final installation.

[edit] Step 1: Understanding Client Requirements

The journey began with a detailed consultation to understand the client’s vision, space constraints, and desired materials. The client wanted a modern, floating staircase that incorporated natural oak treads and glass balustrades to create an open and airy look.

Key requirements:

- Floating effect with minimal visible supports.

- High-quality oak steps for warmth and durability.

- Frameless glass balustrades for unobstructed views.

- Compliance with building regulations.

[edit] Step 2: Concept and Design

Using advanced 3D modeling software, we created a digital rendering of the staircase to visualize the design. This step allowed us to:

- Adjust dimensions and proportions to fit the space perfectly.

- Showcase the floating effect with hidden structural supports.

- Ensure the balustrades aligned seamlessly with the staircase.

The client approved the design after reviewing multiple iterations and refinements.

[edit] Step 3: Material Selection

We carefully selected premium materials to meet both aesthetic and functional requirements:

- Oak Treads: Sourced from sustainably managed forests, the treads were precision-cut and finished with a protective lacquer.

- Glass Balustrades: Tempered glass panels were chosen for their strength and safety, meeting BS EN 12150 standards.

- Steel Fixings: High-grade stainless steel components ensured durability and a sleek finish.

[edit] Step 4: Manufacturing

The manufacturing process combined traditional craftsmanship with cutting-edge technology:

- Oak Treads: Each tread was CNC-machined for precise dimensions and a flawless finish.

- Glass Panels: Custom-cut glass panels were polished and drilled to accommodate the stainless steel fixings.

- Structural Supports: A concealed steel frame was fabricated to achieve the floating effect while ensuring structural integrity.

[edit] Step 5: Installation

Our experienced installation team meticulously assembled the staircase on-site. The process included:

- Installing the Steel Frame: The hidden structural supports were securely anchored to the wall and floor.

- Fixing the Oak Treads: Each tread was mounted onto the frame using concealed fixings, ensuring stability and a seamless appearance.

- Attaching the Glass Balustrades: The frameless glass panels were secured with stainless steel clamps, aligning perfectly with the staircase.

- Final Touches: A stainless steel handrail was installed on the wall for added safety and functionality.

[edit] Challenges and Solutions

Every project has its challenges, and this one was no exception:

- Challenge: Achieving the floating effect without compromising safety.

- Solution: We engineered a hidden steel frame that could support the treads while remaining invisible.

- Challenge: Aligning the glass panels precisely with the staircase.

- Solution: We used laser measurement tools to ensure perfect alignment.

[edit] Final Result

The finished staircase is a masterpiece of modern design and engineering. Its floating oak treads and frameless glass balustrades create a striking visual impact while maintaining practicality and safety. The staircase not only enhances the home’s interior but also reflects the client’s style and vision.

File history

Click on a date/time to view the file as it appeared at that time.

| Date/Time | Thumbnail | Dimensions | User | Comment | |

|---|---|---|---|---|---|

| current | 16:40, 23 January 2025 |  | 1,200 × 1,600 (203 KB) | Continox Ltd (Talk | contribs) | (Central spine - Continox Ltd) |

| 16:35, 23 January 2025 |  | 1,200 × 1,600 (203 KB) | Continox Ltd (Talk | contribs) | (Central spine staircase ) |

- Edit this file using an external application (See the setup instructions for more information)

File usage

There are no pages that link to this file.

Featured articles and news

Editor's broadbrush view on forms of electrical heating in context.

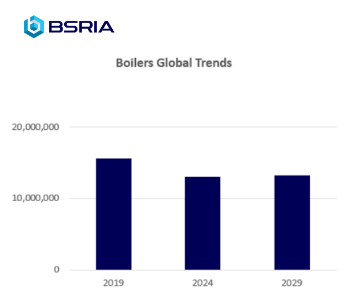

The pace of heating change; BSRIA market intelligence

Electric Dreams, Boiler Realities.

New President of ECA announced

Ruth Devine MBE becomes the 112th President of the Electrical Contractors Association.

New CIAT Professional Standards Competency Framework

Supercedes the 2019 Professional Standards Framework from 1 May 2025.

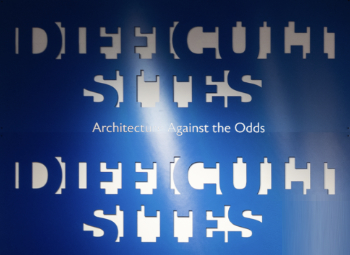

Difficult Sites: Architecture Against the Odds

Free exhibition at the RIBA Architecture Gallery until 31 May.

PPN 021: Payment Spot Checks in Public Sub-Contracts

Published following consultation and influence from ECA.

Designing Buildings reaches 20,000 articles

We take a look back at some of the stranger contributions.

Lessons learned from other industries.

The Buildings of the Malting Industry. Book review.

Conserving places with climate resilience in mind.

Combating burnout.

The 5 elements of seiri, seiton, seiso, seiketsu and shitsuke.

Shading for housing, a design guide

A look back at embedding a new culture of shading.

The Architectural Technology Awards

The AT Awards 2025 are open for entries!

ECA Blueprint for Electrification

The 'mosaic of interconnected challenges' and how to deliver the UK’s Transition to Clean Power.

Grenfell Tower Principal Contractor Award notice

Tower repair and maintenance contractor announced as demolition contractor.