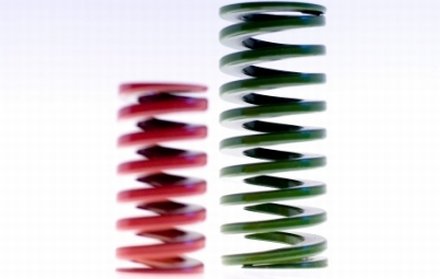

Die springs

Contents |

Introduction

Die springs play an integral role within the manufacturing and engineering industries. Similar to compression springs, die springs are manufactured and built to take a higher load than other springs, making them a valuable tool for a variety of projects.

For a die spring to work without hindrance, there has to be room for it to work. This means the starting point is not the physical dimensions of the die spring, but the installation dimensions.

What are die springs?

Also referred to as ‘high compression springs’, die springs are designed to maintain and withstand great levels of applied stress. These types of springs are made with rectangular wire instead of circular, unlike their ‘compression’ counterparts.

This type of high force compression spring can handle 30% more stress than a standard compression spring. This can be beneficial in extreme and stressful environments, such as handling temperatures rising to 475 degrees.

Properties of die springs

Die springs have a number of unique qualities, the first being the material they are made from. The use of rectangular and square wire is the prime element that gives the die spring its unique property, and it is this larger mass which provides the spring with a greater force.

Die springs are an extremely reliable and consistent spring. They can be manufactured to different strengths, which is shown through the use of different colour codes.

Common uses of die springs

Due to their strength, die springs are used for a wide range of applications within various industries, including:

- Clutches and brakes in the automotive industry.

- Transportation industry.

- Agricultural industry.

The difference between compression and die springs

Springs may look similar, but the different variations of springs all have different characteristics, designed for different purposes. Compression and die springs are two which are similar, but with several differences.

Compression springs function by resisting compressive force. When stress and pressure is applied, their length shortens, allowing them to store energy whilst compressed.

Compression springs are used in a wide range of applications, including:

Die springs differ due to their high force. Die springs are engineered to provide predetermined pressure, meaning they are suited to applications involving extreme conditions, high temperature, high loads or heavy machinery, making them an ideal choice for applications which require high force within a limited area.

They can be engineered to consistently give predetermined physical force at certain compressions, ideal components, for example, in punching and pressing machines.

Related articles on Designing Buildings Wiki

- Compression springs.

- E-spring.

- Flat springs.

- Key qualities of springs.

- Spring materials.

- The importance of gas springs.

- Tension springs v torsion springs.

- Using springs in construction to prevent disaster.

- Large and Hot Coiled Compression Springs

- The Difference Between Tension and Torsion Springs

- The Multiple Uses of Compression Springs

- The Uses of Wire Forms Within the Construction Industry

- Types of spring.

Featured articles and news

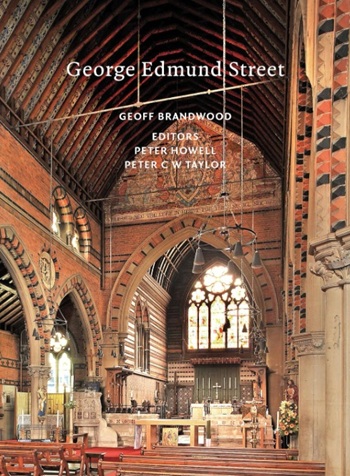

One of the most impressive Victorian architects. Book review.

Common Assessment Standard now with building safety

New CAS update now includes building safety questions as mandatory.

RTPI leader to become new CIOB Chief Executive Officer

Dr Victoria Hills MRTPI, FICE to take over after Caroline Gumble’s departure.

Social and affordable housing, a long term plan for delivery

The “Delivering a Decade of Renewal for Social and Affordable Housing” strategy sets out future path.

A change to adoptive architecture

Effects of global weather warming on architectural detailing, material choice and human interaction.

The proposed publicly owned and backed subsidiary of Homes England, to facilitate new homes.

How big is the problem and what can we do to mitigate the effects?

Overheating guidance and tools for building designers

A number of cool guides to help with the heat.

The UK's Modern Industrial Strategy: A 10 year plan

Previous consultation criticism, current key elements and general support with some persisting reservations.

Building Safety Regulator reforms

New roles, new staff and a new fast track service pave the way for a single construction regulator.

Architectural Technologist CPDs and Communications

CIAT CPD… and how you can do it!

Cooling centres and cool spaces

Managing extreme heat in cities by directing the public to places for heat stress relief and water sources.

Winter gardens: A brief history and warm variations

Extending the season with glass in different forms and terms.

Restoring Great Yarmouth's Winter Gardens

Transforming one of the least sustainable constructions imaginable.

Construction Skills Mission Board launch sector drive

Newly formed government and industry collaboration set strategy for recruiting an additional 100,000 construction workers a year.

New Architects Code comes into effect in September 2025

ARB Architects Code of Conduct and Practice available with ongoing consultation regarding guidance.

Welsh Skills Body (Medr) launches ambitious plan

The new skills body brings together funding and regulation of tertiary education and research for the devolved nation.

Paul Gandy FCIOB announced as next CIOB President

Former Tilbury Douglas CEO takes helm.