Advantages and Disadvantages of Carbon Steel Plate

[edit] Uses of carbon steel plate

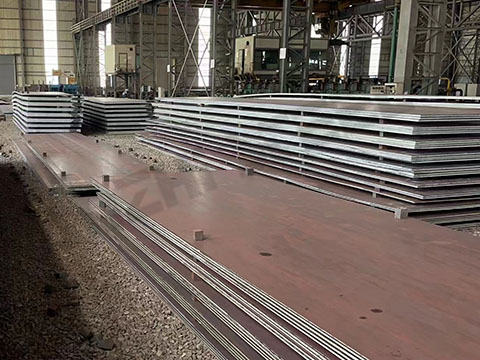

Carbon steel plate is one of the most commonly used steel materials. It can be found in many industries such as general manufacturing, light industry, construction, automobiles, transportation, energy, etc. It is easy to fabricate and relatively cheap in price, making it popular in many different countries.

[edit] Advantages of carbon steel plate

There are several advantages to choosing carbon steel plate over other forms of steel:

- Robust Construction: Carbon steel plate, has a higher concentration of carbon than other types of steel, generally between 0.02%-2.11%, which can solidify the metal’s interior structure and enhance its strength. As the percentage of carbon gets larger, the steel will become harder.

- Good Mechanical Properties: Carbon plate can be cut, welded, or processed easily due to its good abrasion resistance and machinability. While carbon steel can still stress and break under pressure, it’s less likely than with other types of steel.

- Various Specifications: Carbon steel plate is available in a wide selection of thicknesses, sizes, grades, and types.

- Wide Applications: This material can be used in many applications, from small household items to structural frames, wires, automobile components, surgical instruments, bolts, stampings, cranks, gears, bars, spring steel, railway tracks, cookware, pipelines, fencing, nails, etc.

- Affordability: It is cheaper than galvanised steel, galvalume steel, aluminium, or stainless steel, making it a popular metal used by many manufacturing companies.

=

Disadvantages of carbon steel plate =

There are some disadvantages of carbon steel plate:

- The increase in carbon content has two effects: increasing strength and decreasing plasticity of steel. Therefore, high carbon steel plates can be difficult to work with. It can’t be easily bent or molded into different shapes, thus limiting its utility in certain applications.

- Corrosion protection performance is not good. Carbon steel is more susceptible to rust and corrosion when exposed to moisture and oxygen. This is because it has no protective coating on its surface. Carbon steel products can be galvanised for higher corrosion resistance. In view of this, some manufacturers use it as substrate for galvanised and galvalume steel products.

[edit] Related articles on Designing Buildings

- Aluminium.

- Cast iron.

- Concrete-steel composite structures.

- Galvanised steel.

- Major cast metal components.

- Metal fabrication.

- Metal roofing.

- Rust.

- Stainless steel.

- Stainless steel vs. galvanised steel.

- Structural steelwork.

- Super-strength steel structures.

- Types of metal.

- Types of steel.

- Weathering steel.

Featured articles and news

UKCW London to tackle sector’s most pressing issues

AI and skills development, ecology and the environment, policy and planning and more.

Managing building safety risks

Across an existing residential portfolio; a client's perspective.

ECA support for Gate Safe’s Safe School Gates Campaign.

Core construction skills explained

Preparing for a career in construction.

Retrofitting for resilience with the Leicester Resilience Hub

Community-serving facilities, enhanced as support and essential services for climate-related disruptions.

Some of the articles relating to water, here to browse. Any missing?

Recognisable Gothic characters, designed to dramatically spout water away from buildings.

A case study and a warning to would-be developers

Creating four dwellings... after half a century of doing this job, why, oh why, is it so difficult?

Reform of the fire engineering profession

Fire Engineers Advisory Panel: Authoritative Statement, reactions and next steps.

Restoration and renewal of the Palace of Westminster

A complex project of cultural significance from full decant to EMI, opportunities and a potential a way forward.

Apprenticeships and the responsibility we share

Perspectives from the CIOB President as National Apprentice Week comes to a close.

The first line of defence against rain, wind and snow.

Building Safety recap January, 2026

What we missed at the end of last year, and at the start of this...

National Apprenticeship Week 2026, 9-15 Feb

Shining a light on the positive impacts for businesses, their apprentices and the wider economy alike.

Applications and benefits of acoustic flooring

From commercial to retail.

From solid to sprung and ribbed to raised.

Strengthening industry collaboration in Hong Kong

Hong Kong Institute of Construction and The Chartered Institute of Building sign Memorandum of Understanding.

A detailed description from the experts at Cornish Lime.