The uses of wire forms in construction

Contents |

Introduction

Springs and wire forms are important within a wide range of industries. They are one of the most versatile parts within a range of products and can be designed and manufactured in an array of materials depending on specification.

Wire forms are wires that have been bent into a specific shape to fulfil a purpose, one commonly recognised wire form is the spring. Wire forms can be found in almost every industry, including:

- Agricultural

- Construction

- HVAC

- Injection moulding

- Aerospace

- Automotive

- Electronics

- Medical devices

- Petroleum

What are wire forms?

Wire forms are used for a wide array of applications, most commonly headsets and computer brace devices.

Wire forms can be manipulated into certain shapes, sizes and configured to fit the need of any design. They can be made in simple beams or a cantilever design. They can be made in coils or springs using various thicknesses or small rings of differing diameters.

Manufacturers of wire forms can custom make forms to suit the requirements of a task using computer engineering. The wire used within a wire form can be made of any suitable metal, varying on the specific need, such as; stainless steel, copper, or aluminium.

Common uses of wire forms

- Battery contacts: One of the most common applications for wire forms. Battery contacts are designed to have a spiral spring with a leg which can later be welded into a base. This type of application requires a nickel material.

- Mousetraps and safety pins: Wire forms can be found in this common household item. The front section of a mouse trap is a prime example of a common wire form design. A similar design is used for safety pins.

- Large wire applications: A common larger wire application is wire handles. Handles can be manufactured with differing wire sizes that are designed to slip into a hole at either end with a shaped handle.

- Light fixtures: The lighting industry is one of the most common sectors to use wire forms due to their durability and tolerance. Simple wire forms are designed to safely hold a lighting fixture in place.

- Electrical applications: Wire forms are used in a variety of electrical applications. Wire forms are bent into clips that are used to hold electrical wires in place, coated in tin plated copper.

- Hooks: These are used as a point of connection between two parts or components. The open end of the hook allows another item to be connected or suspended by fitting the second object around this point.

Uses within construction

Within construction, wire forms are most commonly used for equipment. Wire forms are created and designed for power tools and hand tools that can withstand the tight tolerances this type of equipment experiences. Wire forms follow a detailed manufacturing process, requiring exacting precision.

Manufacture

Wire forms are created and manufactured through these quick steps:

- Wire is fed through a machine to the bending head.

- The teeth or swage are formed by passing the wire through a form.

- A machine unit is used to cut and roll the wire to the ideal length and diameter.

- The bending head takes over, giving the threaded hook its shape.

Torsional, compression and extension are the three main types of wire form springs.

Find out more

Related articles on Designing Buildings Wiki

- Key Qualities of Springs

- Using Springs in Construction to Prevent Disaster

- Compression springs

- Torsion Springs and Their Benefits

- Extension Springs

- Spotlight on Compression Springs

- The Difference Between Tension and Torsion Springs

- The Multiple Uses of Compression Springs

--European Springs and Pressings Ltd 17:02, 16 Apr 2018 (BST)

Featured articles and news

Homes England supports Greencore Homes

42 new build affordable sustainable homes in Oxfordshire.

Zero carbon social housing: unlocking brownfield potential

Seven ZEDpod strategies for brownfield housing success.

CIOB report; a blueprint for SDGs and the built environment

Pairing the Sustainable Development Goals with projects.

Types, tests, standards and fires relating to external cladding

Brief descriptions with an extensive list of fires for review.

Latest Build UK Building Safety Regime explainer published

Key elements in one short, now updated document.

UKGBC launch the UK Climate Resilience Roadmap

First guidance of its kind on direct climate impacts for the built environment and how it can adapt.

CLC Health, Safety and Wellbeing Strategy 2025

Launched by the Minister for Industry to look at fatalities on site, improving mental health and other issues.

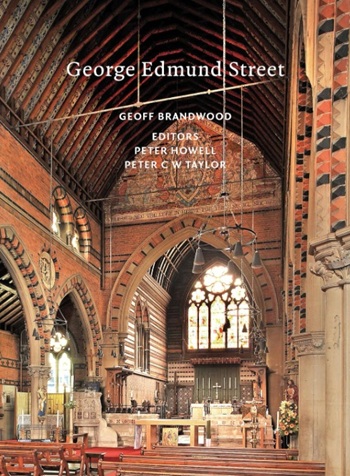

One of the most impressive Victorian architects. Book review.

Common Assessment Standard now with building safety

New CAS update now includes mandatory building safety questions.

RTPI leader to become new CIOB Chief Executive Officer

Dr Victoria Hills MRTPI, FICE to take over after Caroline Gumble’s departure.

Social and affordable housing, a long term plan for delivery

The “Delivering a Decade of Renewal for Social and Affordable Housing” strategy sets out future path.

A change to adoptive architecture

Effects of global weather warming on architectural detailing, material choice and human interaction.

The proposed publicly owned and backed subsidiary of Homes England, to facilitate new homes.

How big is the problem and what can we do to mitigate the effects?

Overheating guidance and tools for building designers

A number of cool guides to help with the heat.

The UK's Modern Industrial Strategy: A 10 year plan

Previous consultation criticism, current key elements and general support with some persisting reservations.

Building Safety Regulator reforms

New roles, new staff and a new fast track service pave the way for a single construction regulator.