Die springs

Contents |

Introduction

Die springs play an integral role within the manufacturing and engineering industries. Similar to compression springs, die springs are manufactured and built to take a higher load than other springs, making them a valuable tool for a variety of projects.

For a die spring to work without hindrance, there has to be room for it to work. This means the starting point is not the physical dimensions of the die spring, but the installation dimensions.

What are die springs?

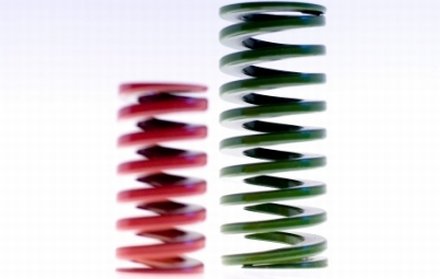

Also referred to as ‘high compression springs’, die springs are designed to maintain and withstand great levels of applied stress. These types of springs are made with rectangular wire instead of circular, unlike their ‘compression’ counterparts.

This type of high force compression spring can handle 30% more stress than a standard compression spring. This can be beneficial in extreme and stressful environments, such as handling temperatures rising to 475 degrees.

Properties of die springs

Die springs have a number of unique qualities, the first being the material they are made from. The use of rectangular and square wire is the prime element that gives the die spring its unique property, and it is this larger mass which provides the spring with a greater force.

Die springs are an extremely reliable and consistent spring. They can be manufactured to different strengths, which is shown through the use of different colour codes.

Common uses of die springs

Due to their strength, die springs are used for a wide range of applications within various industries, including:

- Clutches and brakes in the automotive industry.

- Transportation industry.

- Agricultural industry.

The difference between compression and die springs

Springs may look similar, but the different variations of springs all have different characteristics, designed for different purposes. Compression and die springs are two which are similar, but with several differences.

Compression springs function by resisting compressive force. When stress and pressure is applied, their length shortens, allowing them to store energy whilst compressed.

Compression springs are used in a wide range of applications, including:

Die springs differ due to their high force. Die springs are engineered to provide predetermined pressure, meaning they are suited to applications involving extreme conditions, high temperature, high loads or heavy machinery, making them an ideal choice for applications which require high force within a limited area.

They can be engineered to consistently give predetermined physical force at certain compressions, ideal components, for example, in punching and pressing machines.

Related articles on Designing Buildings Wiki

- Compression springs.

- E-spring.

- Flat springs.

- Key qualities of springs.

- Spring materials.

- The importance of gas springs.

- Tension springs v torsion springs.

- Using springs in construction to prevent disaster.

- Large and Hot Coiled Compression Springs

- The Difference Between Tension and Torsion Springs

- The Multiple Uses of Compression Springs

- The Uses of Wire Forms Within the Construction Industry

- Types of spring.

Featured articles and news

A case study and a warning to would-be developers

Creating four dwellings... after half a century of doing this job, why, oh why, is it so difficult?

Reform of the fire engineering profession

Fire Engineers Advisory Panel: Authoritative Statement, reactions and next steps.

Restoration and renewal of the Palace of Westminster

A complex project of cultural significance from full decant to EMI, opportunities and a potential a way forward.

Apprenticeships and the responsibility we share

Perspectives from the CIOB President as National Apprentice Week comes to a close.

The first line of defence against rain, wind and snow.

Building Safety recap January, 2026

What we missed at the end of last year, and at the start of this...

National Apprenticeship Week 2026, 9-15 Feb

Shining a light on the positive impacts for businesses, their apprentices and the wider economy alike.

Applications and benefits of acoustic flooring

From commercial to retail.

From solid to sprung and ribbed to raised.

Strengthening industry collaboration in Hong Kong

Hong Kong Institute of Construction and The Chartered Institute of Building sign Memorandum of Understanding.

A detailed description from the experts at Cornish Lime.

IHBC planning for growth with corporate plan development

Grow with the Institute by volunteering and CP25 consultation.

Connecting ambition and action for designers and specifiers.

Electrical skills gap deepens as apprenticeship starts fall despite surging demand says ECA.

Built environment bodies deepen joint action on EDI

B.E.Inclusive initiative agree next phase of joint equity, diversity and inclusion (EDI) action plan.

Recognising culture as key to sustainable economic growth

Creative UK Provocation paper: Culture as Growth Infrastructure.