Roasting

Roasting, in relation to material science is a process by which a material, usually a metal ore is heated to extreme temperatures in excess air, or heated in very hot air, in order to burn off impurities. It is a form of pyrometallurgy, which also includes other thermal treatments such as smelting and calcination. During roasting the material reaction is hotter than the surroundings and thus releases heat (exothermic) unlike calcination where the treated material remains cooler than its surroundings thus absorbing heat (endothermic).

There are many different types of roasters which have developed from the early open hearth roasters to furnace based or closed systems, some of these include; fluidised bed roasters, multiple hearth roasters, flash roasters, chlorinators, rotary kilns and blast roaster (or sinters). The different types of roasters and roasting methods are often referred to by the specific reaction and thus the product being sought, some of these are listed here;

- Oxidising roasts remove all or part of the sulphur from sulfide metal compound. The sulfide mineral, sulfide is converted to an oxide, and the gas sulphur dioxide is released, which can be used to used to produce sulfuric acid and to process for example in zinc, copper and nickel from their mineral ores.

- Sulfatizing roasts result in the formation of metallic sulfates (instead of oxides) from sulfides, and are used to process for example in zinc, copper and nickel from the mineral ore.

- Reduction roasts reduce or completely remove the oxide material the metal, effectively removing oxygen from a component of an ore, usually through the use of carbon monoxide (CO) - this is used iron ores. It has a very close relationship with the smelting process, also called reduction smelting.

- Chloridizing roasts change metallic oxides into chlorides through oxidation or reduction, by heating them with a chlorine solution such as chlorine gas, hydrochloric acid gas, ammonium or sodium chloride. Metals such as titanium, uranium and berylium are processed this way.

- Volatizing roasts eliminate unstable oxides by converting them to gas. This is used to produce zinc oxide and arsenic trioxide.

Other forms of roasting include what is called magnetic roasting and sinter roasting. Together all of these methods create environments to separate, process or purify materials through oxidation, reduction, chlorination, sulfation, or pyro-hydrolysis. These processes are used to purify high value metals such as gold, silver, and platinum as well as industrial metals such as zinc, copper, lead, and nickel in particular from sulfide minerals.

Apart from the emissions related to fuel sources, the processes themselves, in particularly the earlier open hearth methods, released large amounts of toxic gases and substances into environments local to the process plants, these pollutants significantly impact natural ecosystems in the vicinity for decades.

The production and smelting of ores is included by reference in The Environmental Permitting (England and Wales) Regulations 2016. The environmental impact of mining and processing of metal ores is an extremely complex issue due to the broad nature of different metals. Whilst the levels of recycled metals has increased, the impacts of mineral mining remain significant. Full life cycle assessments and Environmental Product Declarations (EPDs) for specific materials covering various impacts through the life cycle are the most assured way to assess the environmental impact of a product, in particular one with numerous processing steps.

[edit] Related articles on Designing Buildings

Featured articles and news

Latest Build UK Building Safety Regime explainer published

Key elements in one short, now updated document.

UKGBC launch the UK Climate Resilience Roadmap

First guidance of its kind on direct climate impacts for the built environment and how it can adapt.

CLC Health, Safety and Wellbeing Strategy 2025

Launched by the Minister for Industry to look at fatalities on site, improving mental health and other issues.

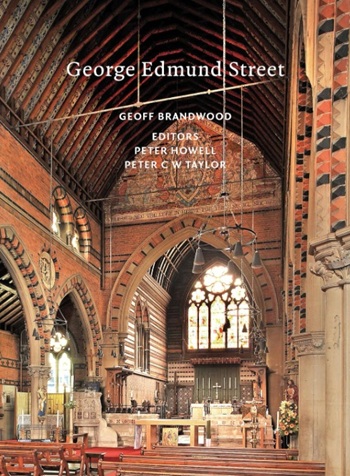

One of the most impressive Victorian architects. Book review.

Common Assessment Standard now with building safety

New CAS update now includes mandatory building safety questions.

RTPI leader to become new CIOB Chief Executive Officer

Dr Victoria Hills MRTPI, FICE to take over after Caroline Gumble’s departure.

Social and affordable housing, a long term plan for delivery

The “Delivering a Decade of Renewal for Social and Affordable Housing” strategy sets out future path.

A change to adoptive architecture

Effects of global weather warming on architectural detailing, material choice and human interaction.

The proposed publicly owned and backed subsidiary of Homes England, to facilitate new homes.

How big is the problem and what can we do to mitigate the effects?

Overheating guidance and tools for building designers

A number of cool guides to help with the heat.

The UK's Modern Industrial Strategy: A 10 year plan

Previous consultation criticism, current key elements and general support with some persisting reservations.

Building Safety Regulator reforms

New roles, new staff and a new fast track service pave the way for a single construction regulator.

Architectural Technologist CPDs and Communications

CIAT CPD… and how you can do it!

Cooling centres and cool spaces

Managing extreme heat in cities by directing the public to places for heat stress relief and water sources.

Winter gardens: A brief history and warm variations

Extending the season with glass in different forms and terms.

Restoring Great Yarmouth's Winter Gardens

Transforming one of the least sustainable constructions imaginable.