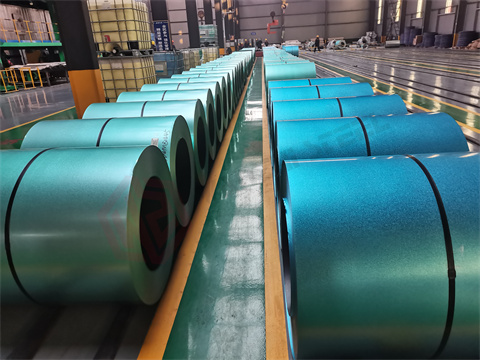

Color Coated Steel Coil

Contents |

[edit] Specification

Colour coated steel coils are painted in a variety of colours for aesthetic and protective purposes. Coatings help prolong the lifespan of the steel by protecting it from corrosion and damage. A variety of standard colours, as well as bespoke colours and design are available. The base metal is galvanised steel, cold rolled steel and galvalume steel, typically between 0.2 mm and 1.2 mm thick, with a variable width between 600 mm and 1,250 mm.

[edit] Uses

Steel coils are used in numerous industries for a variety purposes, in the construction industry, as a roof or cladding material, and the automotive industry, for interior and exterior applications. Colour coated steel coils can be seen on painted roofs, fenders, hoods, bumpers, and door panels as well as in furniture, lamps, and general consumer goods.

[edit] Manufacture

The procedure of making colour coated steel coils involves three steps:

- Step 1 - The base metal is cleaned and pre-treated to remove rust, oil, and other contaminants.

- Step 2 - A primer coat is applied to help the paint adhere to the metal surface. Once dry, the coil is then fed to a painting line to be coated with one or more layers of paint.

- Step 3 - After application, the coil is oven-cured to guarantee a lengthy-lasting finish and then quality checked.

[edit] Benefits

- Durable.

- Resistant to deterioration.

- Easier to keep clean and maintain.

- Simple colour selection.

- Protection against the elements.

[edit] Quality checks

Quality checks are a crucial part of any manufacturing process, and that is certainly true for the creation of colour coated steel coils. There are a number of different tests which can be used to assess the quality of the steel coils, including tests for thickness, width, flatness, colour uniformity, gloss level, and so on. By carefully conducting these quality checks each and every stage of production, manufacturers can ensure that their products fulfil the highest standards.

[edit] Related articles on Designing Buildings

Featured articles and news

UKCW London to tackle sector’s most pressing issues

AI and skills development, ecology and the environment, policy and planning and more.

Managing building safety risks

Across an existing residential portfolio; a client's perspective.

ECA support for Gate Safe’s Safe School Gates Campaign.

Core construction skills explained

Preparing for a career in construction.

Retrofitting for resilience with the Leicester Resilience Hub

Community-serving facilities, enhanced as support and essential services for climate-related disruptions.

Some of the articles relating to water, here to browse. Any missing?

Recognisable Gothic characters, designed to dramatically spout water away from buildings.

A case study and a warning to would-be developers

Creating four dwellings... after half a century of doing this job, why, oh why, is it so difficult?

Reform of the fire engineering profession

Fire Engineers Advisory Panel: Authoritative Statement, reactions and next steps.

Restoration and renewal of the Palace of Westminster

A complex project of cultural significance from full decant to EMI, opportunities and a potential a way forward.

Apprenticeships and the responsibility we share

Perspectives from the CIOB President as National Apprentice Week comes to a close.

The first line of defence against rain, wind and snow.

Building Safety recap January, 2026

What we missed at the end of last year, and at the start of this...

National Apprenticeship Week 2026, 9-15 Feb

Shining a light on the positive impacts for businesses, their apprentices and the wider economy alike.

Applications and benefits of acoustic flooring

From commercial to retail.

From solid to sprung and ribbed to raised.

Strengthening industry collaboration in Hong Kong

Hong Kong Institute of Construction and The Chartered Institute of Building sign Memorandum of Understanding.

A detailed description from the experts at Cornish Lime.