Breaker

Breakers, also known as a hammers or hoe rams, are powerful percussion tools used for breaking up concrete or rock. They can be fitted to excavators and are powered by auxiliary hydraulic systems. They are similar in function and operation to hand-held pneumatic drills.

Breakers are typically used in application such as:

- The demolition of buildings.

- Breaking up pavements or roads.

- Trenching in rock.

- Breaking frozen ground

- Secondary reduction of blasted material.

There are two basic designs for mounted breakers – side-plate and boxed:

- Side-plate breakers have two slabs of steel secured to either side of the breaker mechanism. This arrangement usually leaves the breaker’s front and back open.

- Boxed breakers enclose the breaker mechanism in an outer casing, which acts as a shock-absorbing barrier. This has the advantage of providing more protection from debris. They also tend to be quieter, and there is a reduction in shock and vibration.

Breaker manufacturers tend to use an ‘Impact Energy Class’ rating to identify different breakers, which is loosely based on the breaker’s weight.

Breakers can also be categorised based on the piston-firing system that they use. The three basic types are:

The working tool should be sufficiently lubricated, and cleaned from abrasive dust that can get into the lower portion of the breaker. Some breaker models are fitted with automatic lubrication systems, or a sealing system can be installed if required.

[edit] Find out more

[edit] Related articles on Designing Buildings Wiki

Featured articles and news

Latest Build UK Building Safety Regime explainer published

Key elements in one short, now updated document.

UKGBC launch the UK Climate Resilience Roadmap

First guidance of its kind on direct climate impacts for the built environment and how it can adapt.

CLC Health, Safety and Wellbeing Strategy 2025

Launched by the Minister for Industry to look at fatalities on site, improving mental health and other issues.

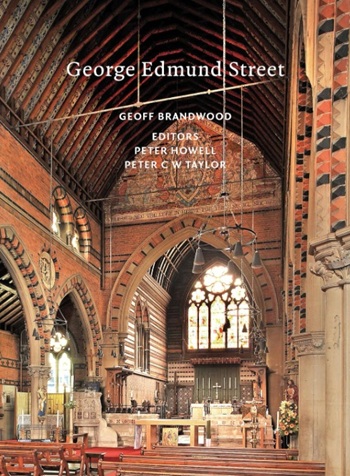

One of the most impressive Victorian architects. Book review.

Common Assessment Standard now with building safety

New CAS update now includes mandatory building safety questions.

RTPI leader to become new CIOB Chief Executive Officer

Dr Victoria Hills MRTPI, FICE to take over after Caroline Gumble’s departure.

Social and affordable housing, a long term plan for delivery

The “Delivering a Decade of Renewal for Social and Affordable Housing” strategy sets out future path.

A change to adoptive architecture

Effects of global weather warming on architectural detailing, material choice and human interaction.

The proposed publicly owned and backed subsidiary of Homes England, to facilitate new homes.

How big is the problem and what can we do to mitigate the effects?

Overheating guidance and tools for building designers

A number of cool guides to help with the heat.

The UK's Modern Industrial Strategy: A 10 year plan

Previous consultation criticism, current key elements and general support with some persisting reservations.

Building Safety Regulator reforms

New roles, new staff and a new fast track service pave the way for a single construction regulator.

Architectural Technologist CPDs and Communications

CIAT CPD… and how you can do it!

Cooling centres and cool spaces

Managing extreme heat in cities by directing the public to places for heat stress relief and water sources.

Winter gardens: A brief history and warm variations

Extending the season with glass in different forms and terms.

Restoring Great Yarmouth's Winter Gardens

Transforming one of the least sustainable constructions imaginable.

Comments

Awesome, but to improve service quality and operational efficiency you need an autolube system for a hydraulic hammer. Grease pump kit includes bolts to mount on the body, 1 hose only and grease pump with a cartridge. Easy to install, no need to make routine greasing procedure every 2 hours. Safe and secure https://buyaftermarketparts.com/articles/71_auto_grease_pumps_for_hydraulic_breakers