Types of Concrete Batching Plants

In the realm of construction and infrastructure development, concrete plays a pivotal role. It's the very foundation upon which we build our cities, homes, and roads. The quality of concrete used in a project can significantly impact its durability and strength. To ensure the highest standards are met, the choice of the right concrete batching plant is crucial. In this article, we'll delve into the various types of concrete batching plants available today, shedding light on their unique characteristics, advantages, and applications.

Contents |

[edit] 1. Stationary Concrete Batching Plant

The stationary concrete batching plant is a fixture at large construction sites, producing a consistent supply of high-quality concrete. This type of plant is known for its reliability and robustness. Key features include:

- High Production Capacity: Stationary plants can produce large volumes of concrete in a relatively short time.

- Precise Mixing: These plants offer precise control over the mix, ensuring uniformity and consistency.

- Long Lifespan: Due to their stationary nature, they are less subject to wear and tear.

Applications: Stationary concrete batching plants are ideal for mega construction projects such as bridges, dams, and high-rise buildings.

[edit] 2. Mobile Concrete Batching Plant

For projects requiring flexibility and mobility, the mobile concrete batching plant is the go-to choice. It offers numerous advantages:

- Portability: These plants can be easily transported to different job sites, saving time and resources.

- Quick Installation: Setting up a mobile plant is swift, allowing for immediate production.

- Adaptability: Mobile plants can be customised to suit various concrete mix designs.

Applications: Mobile concrete batching plants are perfect for smaller projects, remote locations, and infrastructure repair work.

[edit] 3. Compact Concrete Batching Plant

Compact concrete batching plants strike a balance between stationary and mobile plants. They are known for their space-saving design and efficiency:

- Small Footprint: These plants require minimal space, making them suitable for congested construction sites.

- High Performance: Despite their compact size, they deliver excellent production rates.

- Easy Maintenance: Maintenance is simplified due to the plant's manageable size.

Applications: Compact concrete batching plants are versatile and can be used in a wide range of construction projects, including urban development and housing complexes.

[edit] 4. Dry Mix Concrete Batching Plant

In situations where the transportation of wet concrete is impractical, dry mix concrete batching plants come into play:

- Waterless Mixing: Dry mix plants pre-mix the dry ingredients, requiring only water to be added on-site.

- Reduced Wastage: Precise measurements minimise material wastage.

- Cost-Efficiency: They are often more economical for small-scale projects.

Applications: Dry mix concrete batching plants are favoured for remote locations, as well as for projects with limited water supply.

[edit] 5. Central Mix Concrete Batching Plant

Central mix plants are the epitome of precision and quality control:

- Centralised Mixing: These plants have a central mixer, ensuring thorough and consistent blending.

- High-Quality Output: The concrete produced is of the highest quality, meeting stringent standards.

- Automation: They often feature advanced automation systems for precise control.

Applications: Central mix concrete batching plants are used in projects where top-notch quality and precision are non-negotiable, such as major infrastructure development.

[edit] 6. Continuous Concrete Batching Plant

For uninterrupted production, continuous concrete batching plants are the way to go:

- Non-Stop Production: These plants can operate 24/7, ensuring a constant supply of concrete.

- Low Operating Costs: Continuous production reduces startup and shutdown costs.

- High Volume Output: They are designed for high-output applications.

Applications: Continuous concrete batching plants are suitable for large-scale projects that require a constant and uninterrupted supply of concrete.

In conclusion, the choice of a concrete batching plant depends on various factors, including the scale of the project, location, and specific requirements. Each type of plant has its unique strengths and applications, ensuring that there's a suitable option for every construction endeavour.

Featured articles and news

International Electrician Day, 10 June 2025

Celebrating the role of electrical engineers from André-Marie Amperè, today and for the future.

New guide for clients launched at Houses of Parliament

'There has never been a more important time for clients to step up and ...ask the right questions'

The impact of recycled slate tiles

Innovation across the decades.

EPC changes for existing buildings

Changes and their context as the new RdSAP methodology comes into use from 15 June.

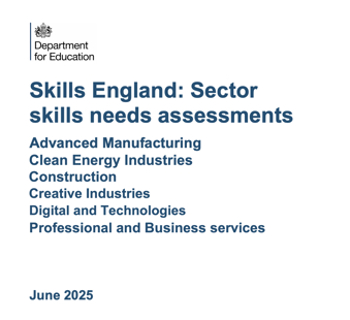

Skills England publishes Sector skills needs assessments

Priority areas relating to the built environment highlighted and described in brief.

BSRIA HVAC Market Watch - May 2025 Edition

Heat Pump Market Outlook: Policy, Performance & Refrigerant Trends for 2025–2028.

Committing to EDI in construction with CIOB

Built Environment professional bodies deepen commitment to EDI with two new signatories: CIAT and CICES.

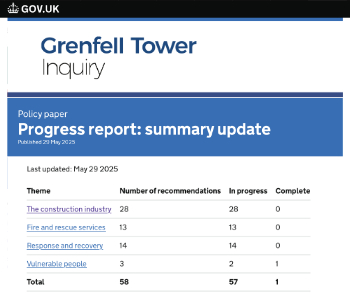

Government Grenfell progress report at a glance

Line by line recomendation overview, with links to more details.

An engaging and lively review of his professional life.

Sustainable heating for listed buildings

A problem that needs to be approached intelligently.

50th Golden anniversary ECA Edmundson apprentice award

Deadline for entries has been extended to Friday 27 June, so don't miss out!

CIAT at the London Festival of Architecture

Designing for Everyone: Breaking Barriers in Inclusive Architecture.

Mixed reactions to apprenticeship and skills reform 2025

A 'welcome shift' for some and a 'backwards step' for others.

Licensing construction in the UK

As the latest report and proposal to licence builders reaches Parliament.

Building Safety Alliance golden thread guidance

Extensive excel checklist of information with guidance document freely accessible.

Fair Payment Code and other payment initiatives

For fair and late payments, need to work together to add value.

Pre-planning delivery programmes and delay penalties

Proposed for housebuilders in government reform: Speeding Up Build Out.

High street health: converting a building for healthcare uses

The benefits of health centres acting as new anchor sites in the high street.