The Properties of Compression Springs

Contents |

[edit] Introduction

Compression springs are the most commonly-used type of spring as well as the most economical, making it an important spring within the manufacturing industry. Aside from manufacturing, they are also used in a range of other industries including:

- Transportation.

- Construction.

- Materials handling.

- Agricultural.

- Aeronautical.

Compression springs can sometimes be confused with torsion springs due to their similarities in appearance; however, they are designed to do very different things.

[edit] What Is a compression spring?

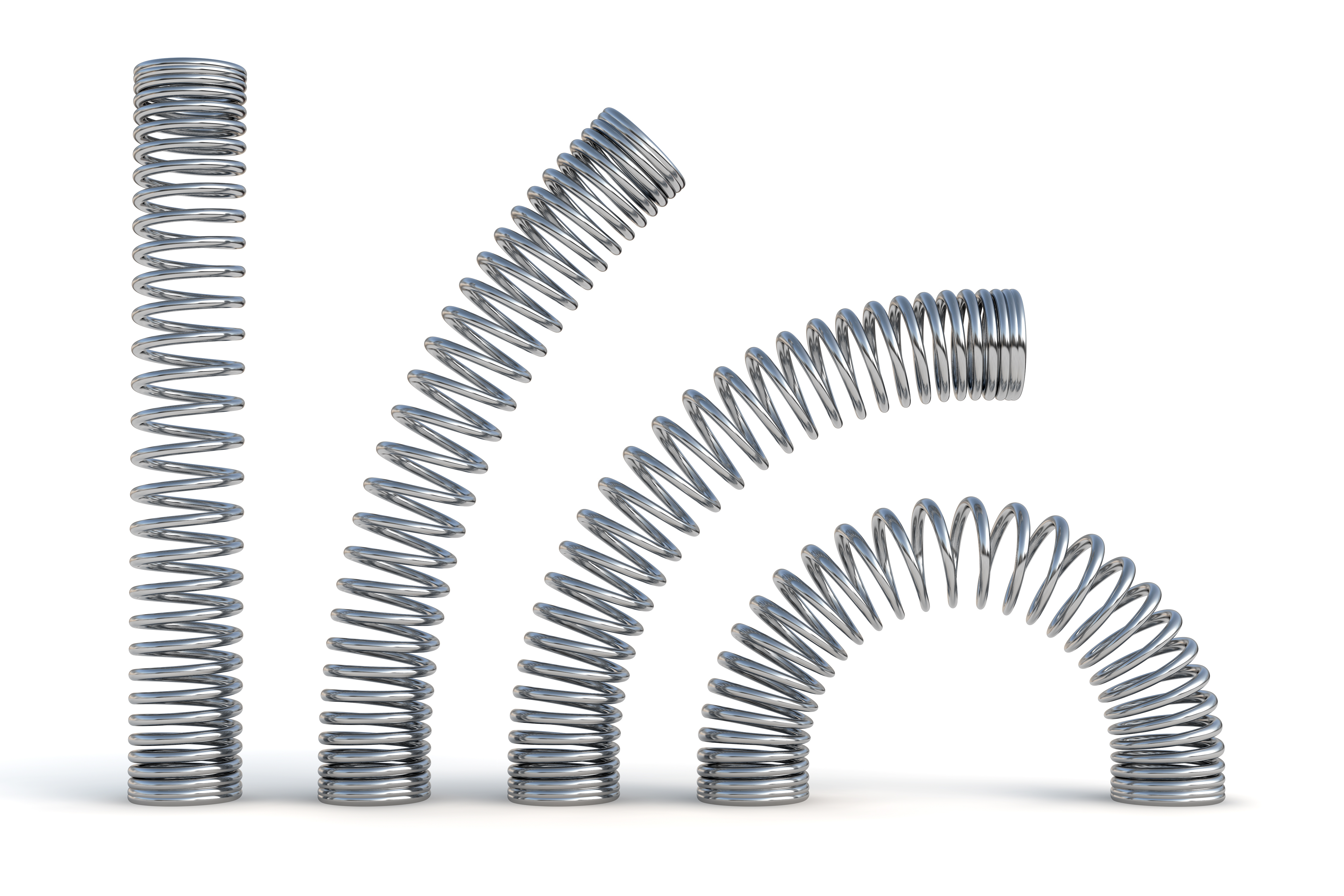

Compression springs are open-coiled springs wound into a helical shape. They are designed to offer resistance to a compressive force applied axially, meaning that they push back when force is applied to them. Helically-wound compression springs are the most common configuration and have an extensive range of uses.

Compression springs can be formed in many different types such as:

- Conical.

- Hourglass.

- Barrel-shaped.

- Torsional.

- Magazine.

They are typically positioned over a rod or fitted into a hole. When subject to pressure by weight on their axis, the spring compresses. As it does this, it gains the potential to push back to its original position.

[edit] History of use

Some form of spring technology has existed for thousands of years. The earliest known application of spring technology is the bow and arrow. Coiled springs, however, did not appear until early in the 15th century.

These first compression springs were used in door locks in the 18th century to ensure that only one specific type of key could be used to unlock a door. They were later used in the first spring-powered clock that evolved into the first watches of the 16th century.

In 1676, British physicist Robert Hooke postulated Hooke’s law, which states that the exertion of a spring is proportional to the load applied to it, so long as this load does not exceed the material’s elastic limit.

[edit] Properties of compression springs

A feature that can set compression springs apart from other types of spring is the tightness of their coils. Compression springs are less tightly coiled than torsion springs and work in the opposite way to other springs – whereas some springs hold things together, compression springs keep things apart.

Compression springs are typically made from metal due to the stiffness of the material, particularly high strength alloys. A compression spring is fully extended when at rest. However, upon compression, the spring will express stored torsional energy in a pushing force. The shape-restoring force is proportional to the deflected distance of the spring.

[edit] Common uses of compression springs

Compression springs have many different purposes and functions. Probably the most famous use of a compression spring is the pogo stick. Thought to be originally patented in 1891, it rose to popularity in the 1970s, loved by children around the world.

Some more common uses of compression springs that we come across every day include:

- Valves.

- Locking doors.

- Railways.

- Electrical switches.

- Large stamping presses.

- Ballpoint pens.

Being the most common type of spring, the bulk of those manufactured are used in engineering, the defence industry and in vehicles.

[edit] Related articles on Designing Buildings Wiki

- Compression springs.

- Die springs.

- E-spring.

- Flat springs.

- Key qualities of springs.

- Large and Hot Coiled Compression Springs.

- Spring materials.

- Tension springs v torsion springs.

- The Difference Between Tension and Torsion Springs.

- The importance of gas springs.

- The Multiple Uses of Compression Springs.

- The Uses of Wire Forms Within the Construction Industry.

- Using springs in construction to prevent disaster.

- Wave springs.

Featured articles and news

Delayed, derailed and devalued

How the UK’s planning crisis is undermining British manufacturing.

How much does it cost to build a house?

A brief run down of key considerations from a London based practice.

The need for a National construction careers campaign

Highlighted by CIOB to cut unemployment, reduce skills gap and deliver on housing and infrastructure ambitions.

AI-Driven automation; reducing time, enhancing compliance

Sustainability; not just compliance but rethinking design, material selection, and the supply chains to support them.

Climate Resilience and Adaptation In the Built Environment

New CIOB Technical Information Sheet by Colin Booth, Professor of Smart and Sustainable Infrastructure.

Turning Enquiries into Profitable Construction Projects

Founder of Develop Coaching and author of Building Your Future; Greg Wilkes shares his insights.

IHBC Signpost: Poetry from concrete

Scotland’s fascinating historic concrete and brutalist architecture with the Engine Shed.

Demonstrating that apprenticeships work for business, people and Scotland’s economy.

Scottish parents prioritise construction and apprenticeships

CIOB data released for Scottish Apprenticeship Week shows construction as top potential career path.

From a Green to a White Paper and the proposal of a General Safety Requirement for construction products.

Creativity, conservation and craft at Barley Studio. Book review.

The challenge as PFI agreements come to an end

How construction deals with inherited assets built under long-term contracts.

Skills plan for engineering and building services

Comprehensive industry report highlights persistent skills challenges across the sector.

Choosing the right design team for a D&B Contract

An architect explains the nature and needs of working within this common procurement route.

Statement from the Interim Chief Construction Advisor

Thouria Istephan; Architect and inquiry panel member outlines ongoing work, priorities and next steps.

The 2025 draft NPPF in brief with indicative responses

Local verses National and suitable verses sustainable: Consultation open for just over one week.