Cool paint

|

|

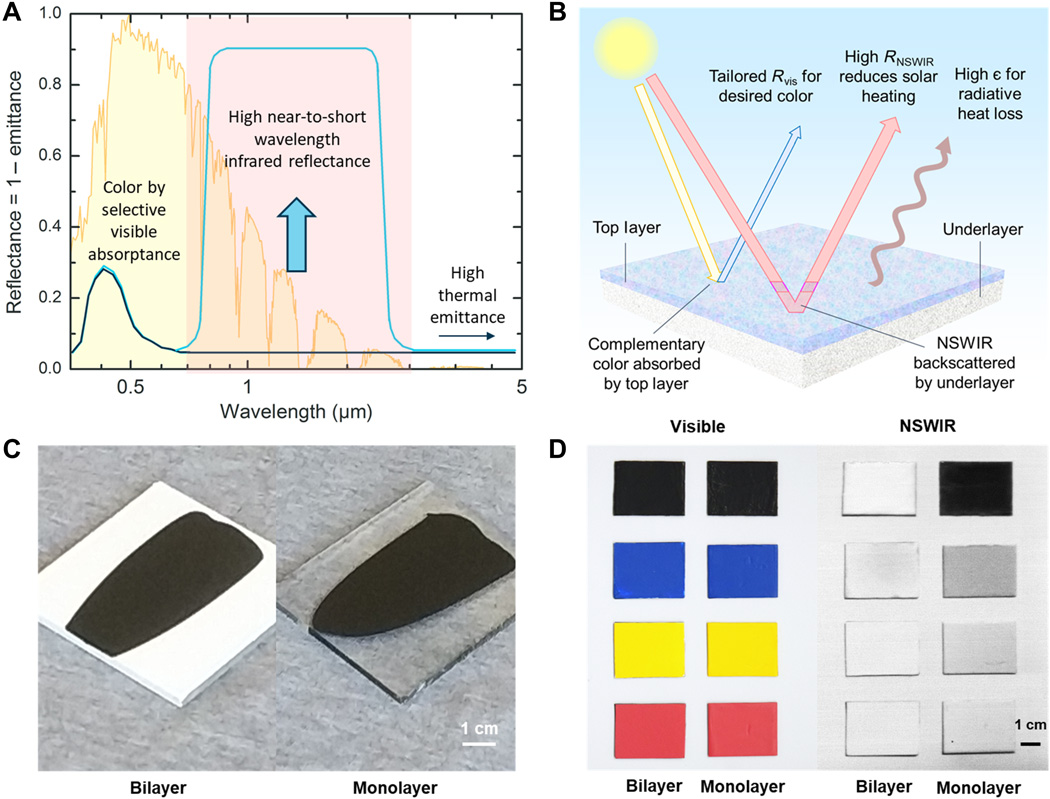

Bilayer coloured radiative coolers (CRCs) for enhanced near-to-short wavelength infrared reflectance (NSWIR).

Photo credits: Photograph C - J.M., Columbia University; Photograph D - S.S., Columbia University. |

Contents |

[edit] Introduction

Paint is a liquid material that can be applied to surfaces to colour, protect and provide texture. In 2020, researchers announced the development of two types of innovative reflective paints that can also serve to cool surfaces and help to reduce energy consumption in buildings.

[edit] Coloured reflective coating

In April 2020, a group of scientists at New York’s Columbia University, under the guidance of Yuan Yang, introduced a bilayer, multicoloured infrared reflective paint. The top layer of this coating is made up of commercial, coloured paint while the bottom layer incorporates an infrared reflective polymer. Regardless of the colour selected for the top layer, the coating maintains its reflective properties.

Historically, paints containing titanium dioxide (TiO2) and colourants tend to absorb near-to-short wavelength infrared reflectance (NSWIR) wavelengths. This usually makes them hotter rather than cooler when exposed to sunlight. However, Yang’s top layer coating selectively absorbs visible wavelengths that are complementary to the desired colour but not others, while the underlayer maximises the distribution of any sunlight transmitted by the top layer.

Consequently, the two layers exhibit similar colours and visible reflectances (RVIS) to those of commercial monolayer paint - but with improved NSWIR. This results in a higher cooling performance and lower temperatures for the bilayers under sunlight.

|

|

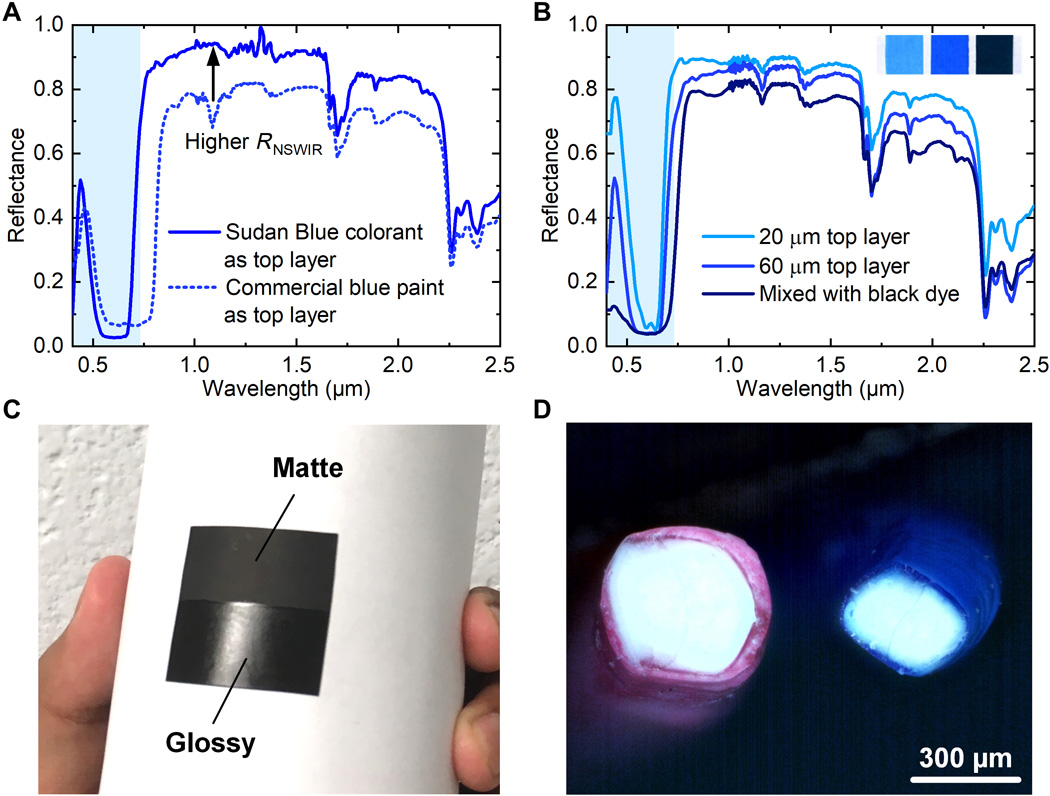

Tuning the coloured top layer in the bilayer cooling paints.

Photo credits: Photograph C - J.M., Columbia University; Photograph D - C.-C.T., Columbia University. |

Test results demonstrated cooler temperatures even with black paint, which typically absorbs heat. In an article in New Scientist, Layal Liverpool writes, “painting an object with a black version of this new coating kept it about 16°C cooler than when an object painted with commercial black paint was exposed to the same amount of sunlight. In another test, the new paint coating was found to be able to maintain its colour despite being placed in an oven at 60°C for 30 days.”

[edit] Super white reflective coating

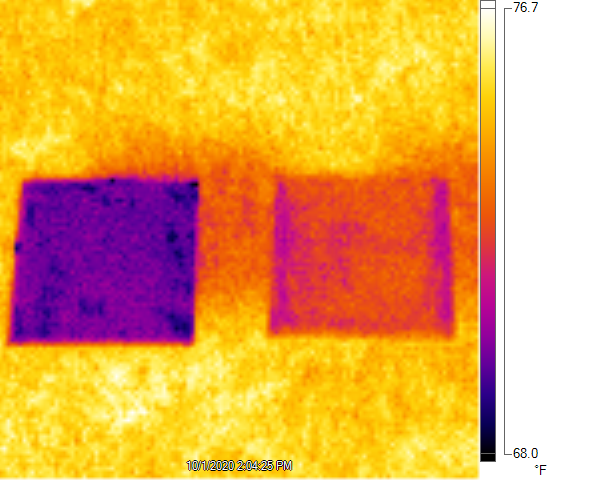

In October 2020, Xiulin Ruan and his colleagues at Indiana’s Purdue University introduced a new type of white paint with 95.5% solar reflectance. Most typical commercial heat rejecting paints reflect between 80%-90% of sunlight and cannot achieve temperatures below their surroundings. This new coating can reduce surface temperatures - without consuming any energy - below that of the surrounding air. It is able to accomplish this even when exposed to sunlight.

The researchers considered more than 100 different material combinations, narrowed them down to 10 and tested about 50 different formulations for each material. They selected a formulation made of calcium carbonate. This compound, used as the paint’s filler, allowed the formulation to behave essentially the same as commercial white paint but with greatly enhanced cooling properties.

These calcium carbonate fillers absorb almost no ultraviolet rays due to a so-called large “band gap,” a result of their atomic structure. They also have a high concentration of particles that are different sizes, allowing the paint to scatter a wider range of wavelengths.

|

|

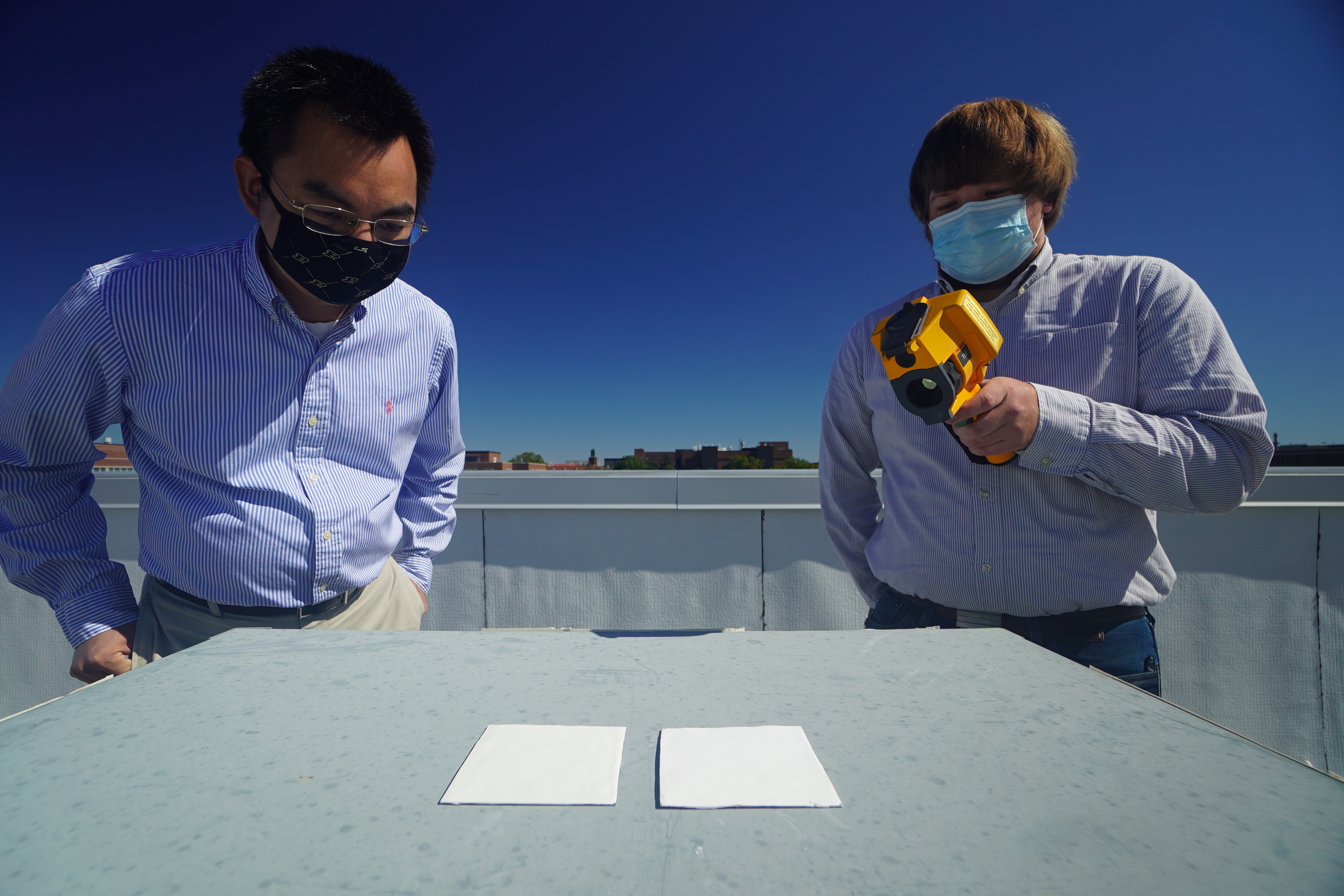

| Purdue researchers Xiulin Ruan (left) and Joseph Peoples (right) use an infrared camera to compare the cooling performance of white paint samples on a rooftop. Credit: Purdue University; photo/Jared Pike. | An infrared camera image shows that white radiative cooling paint developed by Purdue University researchers (left, purple) can stay cooler in direct sunlight compared with commercial white paint. Credit: Purdue University; image/Joseph Peoples. |

The paint’s formulation is based on previous attempts to develop radiative cooling paint that could replace consumer dependence on air conditioning. According to the researchers’ cost estimates, this paint could both cut air conditioning expenses and be cheaper to produce than its commercial alternative.

The researchers are working on developing other paint colours that could have cooling benefits. The team filed an international patent application on this paint formulation through the Purdue Research Foundation Office of Technology Commercialization.

[edit] Related articles on Designing Buildings Wiki

- Albedo in the built environment.

- Cool roofs.

- Earthquake resistant building materials.

- Heat transfer in buildings.

- Paint.

- Paints and coatings.

- Thermal behaviour of architectural fabric structures.

[edit] External resources

- New Scientist, Infrared-reflecting paint can cool buildings even when it is black.

- Purdue University, This white paint could reduce the need for air conditioning by keeping surfaces cooler than surroundings.

- Science Advances, Colored and paintable bilayer coatings with high solar-infrared reflectance for efficient cooling.

- Science Direct, Full Daytime Sub-ambient Radiative Cooling in Commercial-like Paints with High Figure of Merit.

Featured articles and news

The need for a National construction careers campaign

Highlighted by CIOB to cut unemployment, reduce skills gap and deliver on housing and infrastructure ambitions.

AI-Driven automation; reducing time, enhancing compliance

Sustainability; not just compliance but rethinking design, material selection, and the supply chains to support them.

Climate Resilience and Adaptation In the Built Environment

New CIOB Technical Information Sheet by Colin Booth, Professor of Smart and Sustainable Infrastructure.

Turning Enquiries into Profitable Construction Projects

Founder of Develop Coaching and author of Building Your Future; Greg Wilkes shares his insights.

IHBC Signpost: Poetry from concrete

Scotland’s fascinating historic concrete and brutalist architecture with the Engine Shed.

Demonstrating that apprenticeships work for business, people and Scotland’s economy.

Scottish parents prioritise construction and apprenticeships

CIOB data released for Scottish Apprenticeship Week shows construction as top potential career path.

From a Green to a White Paper and the proposal of a General Safety Requirement for construction products.

Creativity, conservation and craft at Barley Studio. Book review.

The challenge as PFI agreements come to an end

How construction deals with inherited assets built under long-term contracts.

Skills plan for engineering and building services

Comprehensive industry report highlights persistent skills challenges across the sector.

Choosing the right design team for a D&B Contract

An architect explains the nature and needs of working within this common procurement route.

Statement from the Interim Chief Construction Advisor

Thouria Istephan; Architect and inquiry panel member outlines ongoing work, priorities and next steps.

The 2025 draft NPPF in brief with indicative responses

Local verses National and suitable verses sustainable: Consultation open for just over one week.

Increased vigilance on VAT Domestic Reverse Charge

HMRC bearing down with increasing force on construction consultant says.

Call for greater recognition of professional standards

Chartered bodies representing more than 1.5 million individuals have written to the UK Government.