Is Welsh timber suitable for use in construction?

|

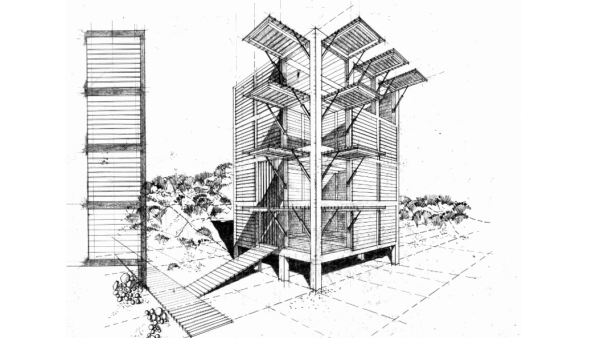

| Modular beach hut designed by Design Research Unit Wales, drawn by Wayne Forster. |

The development of the building envelope using Welsh-grown timber: a study through prototyping.

By Steven Coombs. Published online on 25 January 2018 by Taylor & Francis Online.

[edit] How people can use this research

This research will help designers and contractors assess whether it is advisable or desirable to use Welsh timber for the construction of building envelopes. It explains the species that might be used, how they might be used and what the limitations are.

[edit] What people need to know

There are approximately 306,000 hectares of woodland in Wales covering 15% of the total land area, with an almost even split between broadleaf and coniferous woodland.

However, the crop is considered by many in the industry to have limited commercial value and use. 88% of softwood used by the secondary processing sector is imported, with Welsh-grown softwood used for fencing, pallet making, pulp for paper and as biomass fuel.

Species of Welsh-grown softwood and hardwood are appropriate to use as long as the species’ properties are understood and respected. There is an opportunity for low-tech engineering of short and small section timber (150×150×1200mm), as an output of continuous-cover forestry.

Sitka spruce (30%), larch (8%), Douglas fir (4%), oak (10%), sweet chestnut (<1%) and/or ash (7%) are Welsh-grown timber species with properties that have potential for use.

The current supply and production of Welsh-grown softwood is structurally graded at C16. Any innovations with Welsh-grown softwood must work within standard sawn sizes and C16 structural grade or involve innovation beyond these limitations.

Access the full research paper at: https://www.tandfonline.com/doi/full/10.1080/13602365.2018.1424394

--Designing Buildings 10:28, 22 May 2019 (BST)

[edit] Related articles on Designing Buildings Wiki

Featured articles and news

RTPI leader to become new CIOB Chief Executive Officer

Dr Victoria Hills MRTPI, FICE to take over after Caroline Gumble’s departure.

Social and affordable housing, a long term plan for delivery

The “Delivering a Decade of Renewal for Social and Affordable Housing” strategy sets out future path.

A change to adoptive architecture

Effects of global weather warming on architectural detailing, material choice and human interaction.

The proposed publicly owned and backed subsidiary of Homes England, to facilitate new homes.

How big is the problem and what can we do to mitigate the effects?

Overheating guidance and tools for building designers

A number of cool guides to help with the heat.

The UK's Modern Industrial Strategy: A 10 year plan

Previous consultation criticism, current key elements and general support with some persisting reservations.

Building Safety Regulator reforms

New roles, new staff and a new fast track service pave the way for a single construction regulator.

Architectural Technologist CPDs and Communications

CIAT CPD… and how you can do it!

Cooling centres and cool spaces

Managing extreme heat in cities by directing the public to places for heat stress relief and water sources.

Winter gardens: A brief history and warm variations

Extending the season with glass in different forms and terms.

Restoring Great Yarmouth's Winter Gardens

Transforming one of the least sustainable constructions imaginable.

Construction Skills Mission Board launch sector drive

Newly formed government and industry collaboration set strategy for recruiting an additional 100,000 construction workers a year.

New Architects Code comes into effect in September 2025

ARB Architects Code of Conduct and Practice available with ongoing consultation regarding guidance.

Welsh Skills Body (Medr) launches ambitious plan

The new skills body brings together funding and regulation of tertiary education and research for the devolved nation.

Paul Gandy FCIOB announced as next CIOB President

Former Tilbury Douglas CEO takes helm.

UK Infrastructure: A 10 Year Strategy. In brief with reactions

With the National Infrastructure and Service Transformation Authority (NISTA).