Computer numerical control

|

Computer numerical control (CNC) is the digital manipulation of machines such as drills, lathes and other machine tools by computers and circuitry. Also known as numerical control or computational numerical control, the process comprises a series of numerical values generated by a computer; each of which is assigned to a desired tool or control position to enable the machining of a blank piece of material to precise specifications without requiring a manual operator.

The process dateso back to the first CNC machines built in the 1950s and 60s which relied on punched tape (or perforated paper tape) to communicate the tool position that was controlled by a motor. The process has since been refined and improved by analogue and digital computers.

Under CNC, every object to be manufactured is allocated a G-code (an international standard language) that is stored in the machine and executed by a microcomputer (machine control unit or MCU) attached to the machine. The G-code is a set of instructions – such as the positioning or speed of the tool’s components – that the machine will follow to create or part-create the item in question. Typically, this allows the automation of machine tools such as lathes, mills, routers, lasers and grinders.

In sophisticated manufacturing operations, G-codes are typically derived from the automatic translation of engineers’ CAD drawings into a sequential programme of machine control instructions which are then implemented. A less complex method is writing part-programmes using high-level, part-programming languages.

CNC does not rely on conventional control by cranks, cams and gears. Instead, it allows desired feed rates and cuts to be ‘dialled in’, thereby providing precise, repeatable machine movements that can be optimised for speed, feed and machine cycles.

CNC machines give flexibility of manufacture, especially when variable and complex part geometries are required. Parts can be produced in batches of just a few to several thousand.

[edit] Benefits of computer numerical control

- Provides highly automated, precise manufacturing;

- Does not rely on manual control;

- The part produced is a close match to the original CAD drawing, and

- Gives flexibility of batch size.

[edit] Typical applications of CNC include:

- 3D printing

- Lathes

- Mills

- Water jet cutters, drills, embroidery machines, sheet metal works and glass cutting

- Electrical and/or chemical machining

- Lasers, oxy-fuel and plasma technology

[edit] Related articles on Designing Buildings

- 3D printing.

- Advanced construction technology.

- Building drawing software.

- Building information modelling.

- Common data environment.

- Computer aided design.

- Computer aided manufacturing.

- Computers in building design.

- Computers in tendering.

- Computers in the management of construction.

- Information manager.

- Information and communications technology.

- LEXiCON.

- PAS 1192-2:2013.

- Rapid prototyping.

- Twickenham Studio - London's world-renowned film studio transformed.

- Wikihouse.

Featured articles and news

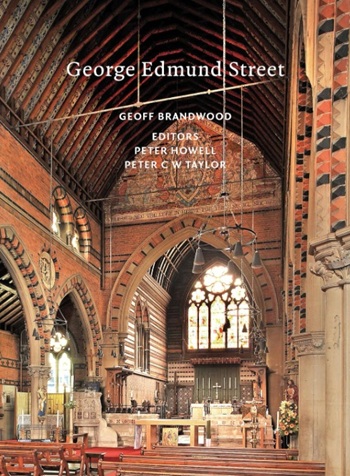

One of the most impressive Victorian architects. Book review.

RTPI leader to become new CIOB Chief Executive Officer

Dr Victoria Hills MRTPI, FICE to take over after Caroline Gumble’s departure.

Social and affordable housing, a long term plan for delivery

The “Delivering a Decade of Renewal for Social and Affordable Housing” strategy sets out future path.

A change to adoptive architecture

Effects of global weather warming on architectural detailing, material choice and human interaction.

The proposed publicly owned and backed subsidiary of Homes England, to facilitate new homes.

How big is the problem and what can we do to mitigate the effects?

Overheating guidance and tools for building designers

A number of cool guides to help with the heat.

The UK's Modern Industrial Strategy: A 10 year plan

Previous consultation criticism, current key elements and general support with some persisting reservations.

Building Safety Regulator reforms

New roles, new staff and a new fast track service pave the way for a single construction regulator.

Architectural Technologist CPDs and Communications

CIAT CPD… and how you can do it!

Cooling centres and cool spaces

Managing extreme heat in cities by directing the public to places for heat stress relief and water sources.

Winter gardens: A brief history and warm variations

Extending the season with glass in different forms and terms.

Restoring Great Yarmouth's Winter Gardens

Transforming one of the least sustainable constructions imaginable.

Construction Skills Mission Board launch sector drive

Newly formed government and industry collaboration set strategy for recruiting an additional 100,000 construction workers a year.

New Architects Code comes into effect in September 2025

ARB Architects Code of Conduct and Practice available with ongoing consultation regarding guidance.

Welsh Skills Body (Medr) launches ambitious plan

The new skills body brings together funding and regulation of tertiary education and research for the devolved nation.

Paul Gandy FCIOB announced as next CIOB President

Former Tilbury Douglas CEO takes helm.