Condensation pipework

Illustrated Guide to Mechanical Cooling (BG 1/2010), written by Kevin Pennycook and published by BSRIA in 2010, defines condensation pipework as: ‘Pipework required to drain condensation from devices such as fan coil units. Condensation pipework needs to be laid to fall to enable the condensate to be drained.’

--BSRIA

[edit] Related articles on Designing Buildings

Featured articles and news

Delivering for tenants; National Retrofit Hub

New report offers recommendations to strengthen energy efficiency standards to protect private renters.

Government consultations for the summer of 2025

A year of Labour, past and present consultations on the environment, the built environment, training and tax.

CMA competitiveness probe of major housing developers

100 million affordable housing contributions committed with further consultation published.

Homes England supports Greencore Homes

42 new build affordable sustainable homes in Oxfordshire.

Zero carbon social housing: unlocking brownfield potential

Seven ZEDpod strategies for brownfield housing success.

CIOB report; a blueprint for SDGs and the built environment

Pairing the Sustainable Development Goals with projects.

Types, tests, standards and fires relating to external cladding

Brief descriptions with an extensive list of fires for review.

Latest Build UK Building Safety Regime explainer published

Key elements in one short, now updated document.

UKGBC launch the UK Climate Resilience Roadmap

First guidance of its kind on direct climate impacts for the built environment and how it can adapt.

CLC Health, Safety and Wellbeing Strategy 2025

Launched by the Minister for Industry to look at fatalities on site, improving mental health and other issues.

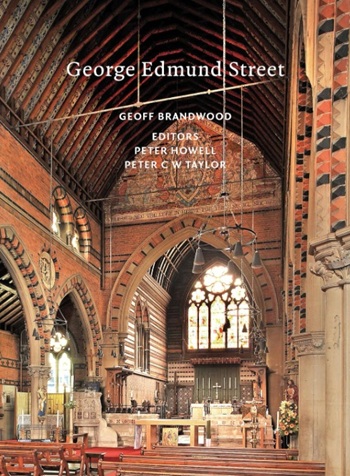

One of the most impressive Victorian architects. Book review.

Common Assessment Standard now with building safety

New CAS update now includes mandatory building safety questions.

RTPI leader to become new CIOB Chief Executive Officer

Dr Victoria Hills MRTPI, FICE to take over after Caroline Gumble’s departure.

Social and affordable housing, a long term plan for delivery

The “Delivering a Decade of Renewal for Social and Affordable Housing” strategy sets out future path.

A change to adoptive architecture

Effects of global weather warming on architectural detailing, material choice and human interaction.

The proposed publicly owned and backed subsidiary of Homes England, to facilitate new homes.

How big is the problem and what can we do to mitigate the effects?

Overheating guidance and tools for building designers

A number of cool guides to help with the heat.

The UK's Modern Industrial Strategy: A 10 year plan

Previous consultation criticism, current key elements and general support with some persisting reservations.

Building Safety Regulator reforms

New roles, new staff and a new fast track service pave the way for a single construction regulator.

Comments

Stainless steel is not a petroleum product. In fact, unlike other piping materials, it does not need to be coated or lined with any material at all. When you need to replace or dispose of stainless steel piping, it is 100% recyclable, reducing its impact on the environment. Up to 50% of all new stainless steel produced in the USA is made from recycled scrap metal

Stainless steel pipe is popular for its corrosion resistance. Limited maintenance, familiar lustre and resistance make it ideal for many installations; it requires both the strength of steel and the resistance to rust and corrosion.

It has a long history of contact with water due to its excellent corrosion resistance. Applications and installations use a wide range of conditions from piping and wastewater treatment to distillation. Standard stainless steel material types for contact with water are 304 and 316, but due to the increased chloride content, higher alloyed stainless steel types are used, such as type 2205, super duplex and super austenitic steels. Stainless steels are 100% recyclable.

When you use stainless steel pipe, you are buying a durable product that will last your business for decades. It is a reliable material that is easy to maintain and install. Stainless steel is low maintenance and is unlikely to need replacing for decades due to its corrosion resistant properties.

Different materials, such as nickel, molybdenum or nitrogen, can be added to stainless steel to enhance its corrosion resistance. Stainless steel can withstand extreme temperatures. By adding different materials to stainless steel, thinner pipe walls and less material can be achieved, meaning less weight gain in the finished product, making it ideal for many commercial and industrial uses.

Another popular type is called seamless stainless steel. It is used for applications that require internal pressure in the pipeline. For example, water treatment or marine applications. It can come in the form of sheets, plates, wire, bars or tubes for surgical instruments, different utensils, cookware or tableware.

For optimum corrosion performance, it is important to consider the chloride content in the water. Choosing the stainless steel pipe is essential whether it is purchased for the garden or for fields of different sizes. For watering large or small fields, stainless steel pipes can be installed and fitted underground. It is wise to coordinate with the experts in the field, for whom the selection or installation of the correct stainless steel pipe is a daily task. It will be helpful to meet with them and discuss your requirements, as the information you receive from the experts will benefit both the business and financial aspects.