Wire rope suspension systems

Contents |

[edit] Introduction

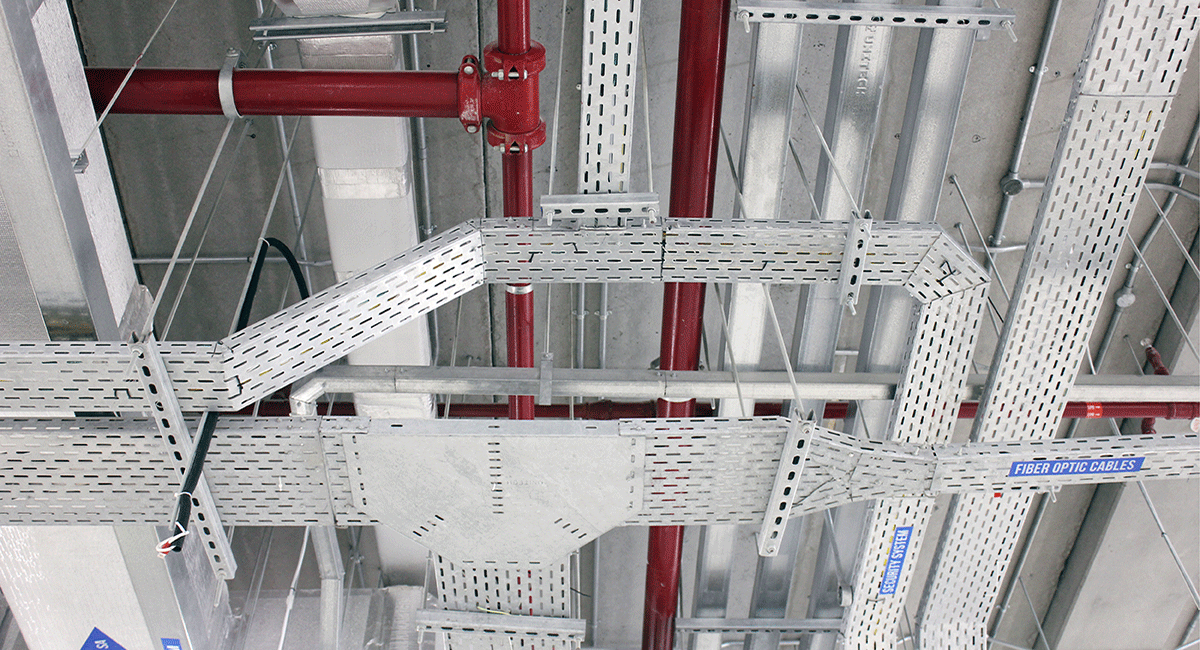

Historically, cable management and support systems have been installed in the same way for decades. It is a system that works, but it's one which often results in over engineered containment with far too many brackets holding up very little cable and a lot of fresh air. However, by utilising the standards and working on manufacturers loading information it is possible to reduce the volume of steel required.

[edit] Standards

IEC 61537:2006, The Cable Tray and Ladder Standard, provides the manufacturer with information on fixing centres and testing methods for containment under load. This results in each manufacturer having load graphs which show what weight their products can carry at varying fixing centres.

Power cables are frequently installed on tray and ladder systems in such a way that it is normal to see 75% of the tray or ladder empty on long runs with the bending radius of the cable being accommodated on a large bend section. Potentially the long straight runs could easily be reduced in size, thereby reducing the volume of steel significantly. The difference in weight between ladder sizes is around 10-15%.

[edit] Related articles on Designing Buildings Wiki

[edit] External resources

Featured articles and news

A case study and a warning to would-be developers

Creating four dwellings... after half a century of doing this job, why, oh why, is it so difficult?

Reform of the fire engineering profession

Fire Engineers Advisory Panel: Authoritative Statement, reactions and next steps.

Restoration and renewal of the Palace of Westminster

A complex project of cultural significance from full decant to EMI, opportunities and a potential a way forward.

Apprenticeships and the responsibility we share

Perspectives from the CIOB President as National Apprentice Week comes to a close.

The first line of defence against rain, wind and snow.

Building Safety recap January, 2026

What we missed at the end of last year, and at the start of this...

National Apprenticeship Week 2026, 9-15 Feb

Shining a light on the positive impacts for businesses, their apprentices and the wider economy alike.

Applications and benefits of acoustic flooring

From commercial to retail.

From solid to sprung and ribbed to raised.

Strengthening industry collaboration in Hong Kong

Hong Kong Institute of Construction and The Chartered Institute of Building sign Memorandum of Understanding.

A detailed description from the experts at Cornish Lime.

IHBC planning for growth with corporate plan development

Grow with the Institute by volunteering and CP25 consultation.

Connecting ambition and action for designers and specifiers.

Electrical skills gap deepens as apprenticeship starts fall despite surging demand says ECA.

Built environment bodies deepen joint action on EDI

B.E.Inclusive initiative agree next phase of joint equity, diversity and inclusion (EDI) action plan.

Recognising culture as key to sustainable economic growth

Creative UK Provocation paper: Culture as Growth Infrastructure.