Vibration Compaction Technology

Contents |

[edit] Introduction

Vibration compaction is one of the methods of manufacturing products from a concrete mix. This technology provides for the compaction of concrete mixtures through the combination of vibration and simultaneous pressure from above.

[edit] Using vibration compaction

For this manufacturing method, semi-dry hard concrete mixtures are used. Such a mixture has a smaller amount of water compared to the mobile mixture, which makes it less ductile.

For moulding by vibration compaction, the plasticity should be P1 with a cone slump of 1 – 4 cm. After completion of compaction, the mould is removed, and the product must continue to maintain its dimensions and appearance.

It is the rigidity of the mixture that ensures the filling of the mould under the action of vibration and its own mass. The traditional technology of vibration compaction involves moulding using deep vibrators. However, there are restrictions on the size of manufactured products.

[edit] Machine made concrete blocks

The process of making concrete block using machines consists of several steps. Concrete mixture is fed into the receiving hopper. Then the mould is filled with a mixture. Mounting loops are mounted in the locking device for moulding and electric vibrators are used to mould the block directly. The process takes approximately three to four minutes.

The technology of vibration compaction and the mobility of the concrete block making machines makes it possible to produce up to 120 blocks per shift.

--Nemp

[edit] Related articles on Designing Buildings Wiki

Featured articles and news

Professional practical experience for Architects in training

The long process to transform the nature of education and professional practical experience in the Architecture profession following recent reports.

A people-first approach to retrofit

Moving away from the destructive paradigm of fabric-first.

International Electrician Day, 10 June 2025

Celebrating the role of electrical engineers from André-Marie Amperè, today and for the future.

New guide for clients launched at Houses of Parliament

'There has never been a more important time for clients to step up and ...ask the right questions'

The impact of recycled slate tiles

Innovation across the decades.

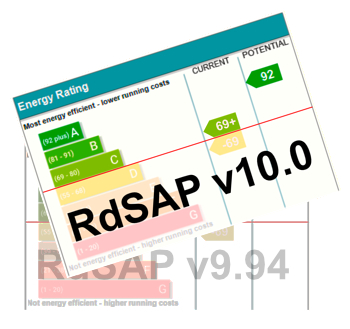

EPC changes for existing buildings

Changes and their context as the new RdSAP methodology comes into use from 15 June.

Skills England publishes Sector skills needs assessments

Priority areas relating to the built environment highlighted and described in brief.

BSRIA HVAC Market Watch - May 2025 Edition

Heat Pump Market Outlook: Policy, Performance & Refrigerant Trends for 2025–2028.

Committing to EDI in construction with CIOB

Built Environment professional bodies deepen commitment to EDI with two new signatories: CIAT and CICES.

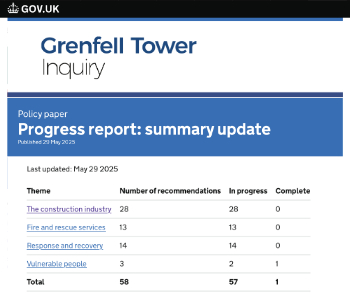

Government Grenfell progress report at a glance

Line by line recomendation overview, with links to more details.

An engaging and lively review of his professional life.

Sustainable heating for listed buildings

A problem that needs to be approached intelligently.

50th Golden anniversary ECA Edmundson apprentice award

Deadline for entries has been extended to Friday 27 June, so don't miss out!

CIAT at the London Festival of Architecture

Designing for Everyone: Breaking Barriers in Inclusive Architecture.

Mixed reactions to apprenticeship and skills reform 2025

A 'welcome shift' for some and a 'backwards step' for others.