Achieving Structural Integrity: The Importance of Accurate Steel Detailing in Building Design

[edit] Introduction

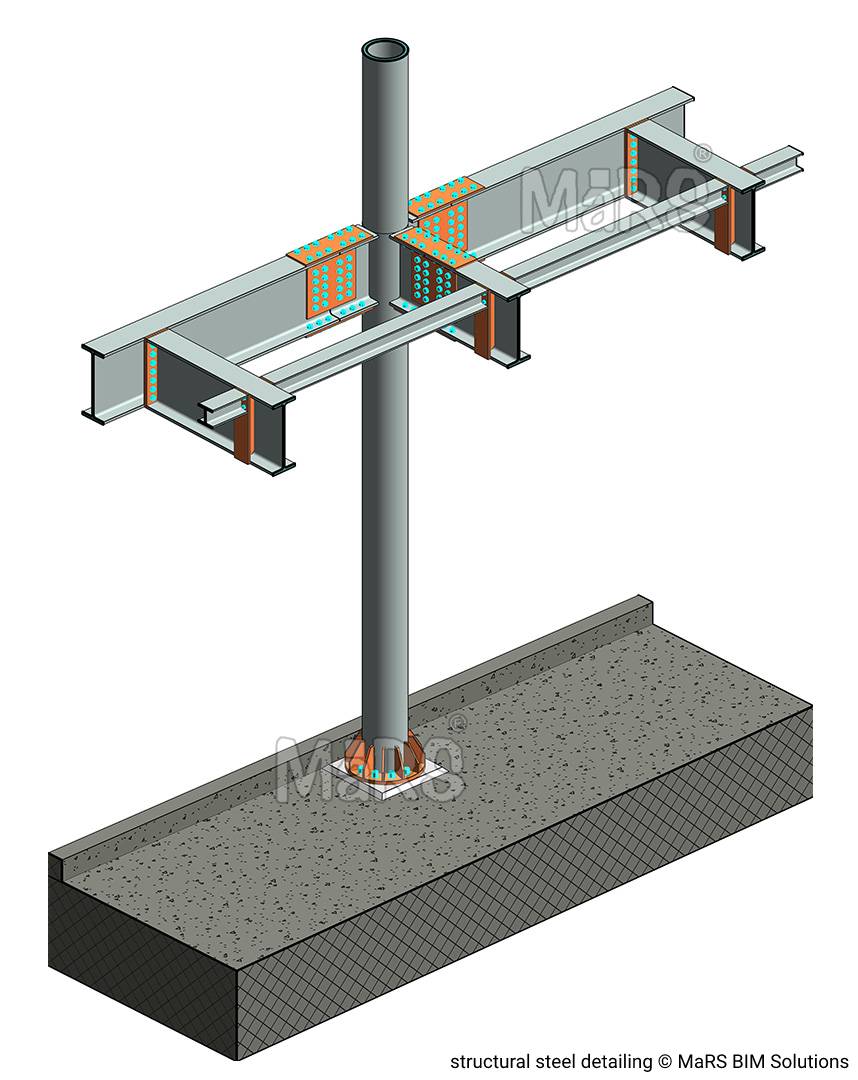

Structural steel detailing is the process of creating detailed drawings and models for the fabrication and construction of steel structures. Structural steel detailing plays a vital role in the construction industry, as it ensures that the final product is safe, accurate, and efficient. The use of structural steel detailing dates back to the 18th century, when steel structures were first used for large-scale construction projects.

[edit] What is Structural Steel Detailing?

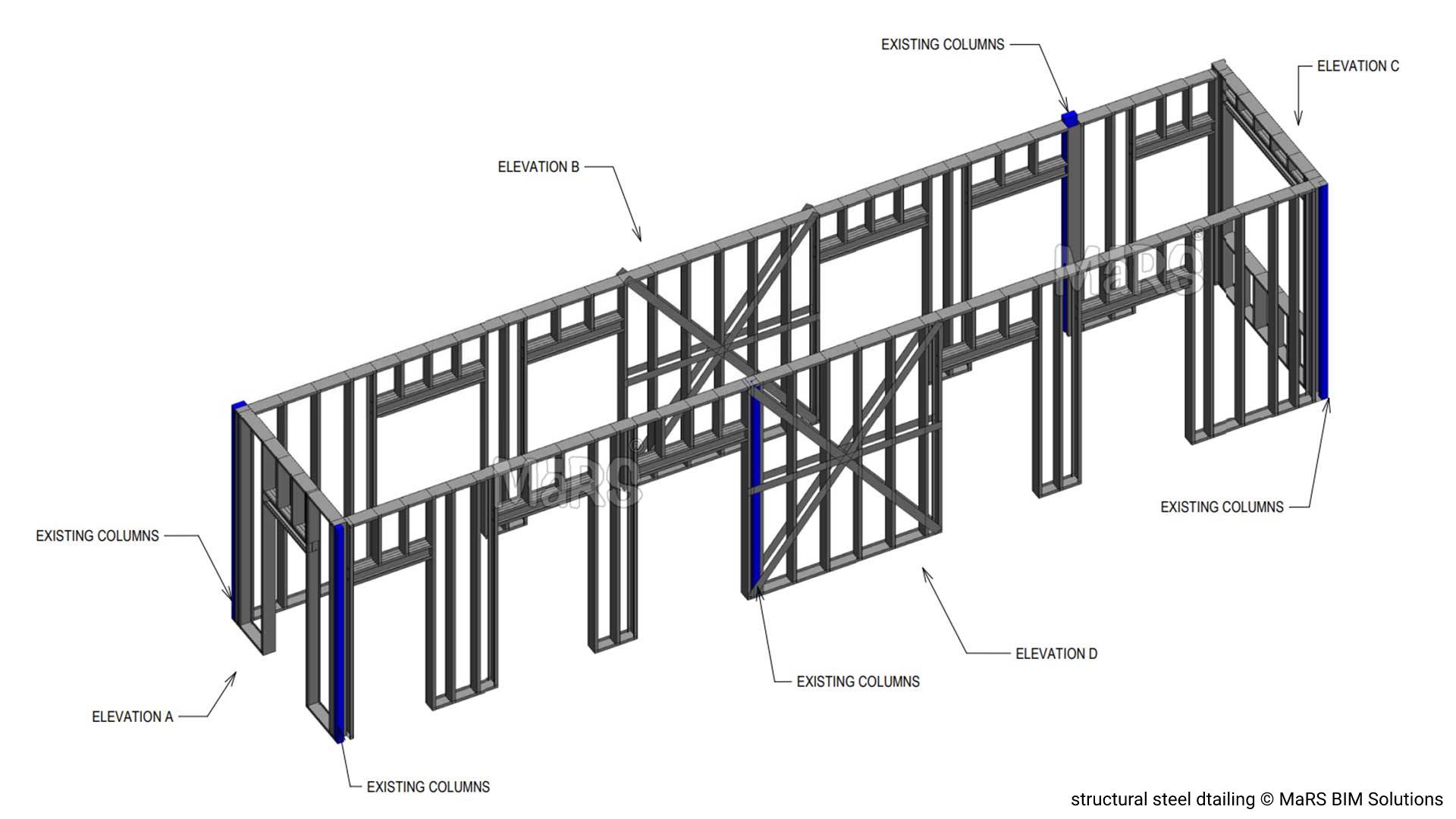

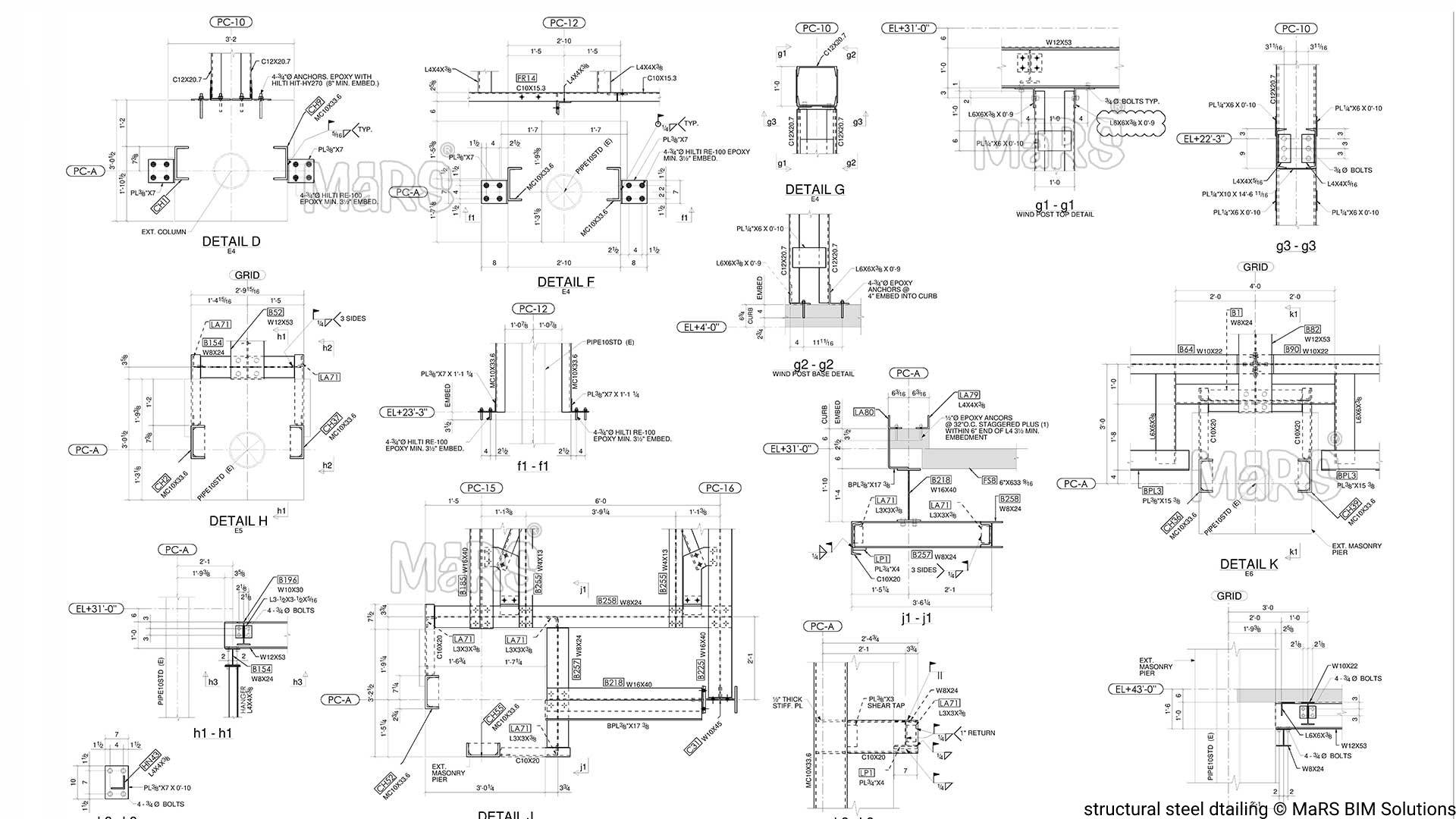

Structural steel detailing is a complex process that involves the creation of detailed drawings and models of steel structures. The structural steel detailer is responsible for creating accurate and precise drawings that show the exact dimensions, sizes, and locations of steel components. The detailer works closely with structural engineers, architects, contractors, and fabricators to ensure that the final product meets the design specifications and is safe and efficient.

[edit] Tools and Software Used in Structural Steel Detailing

Steel Detailing Drawings involves the use of various tools and software to create detailed drawings and models. Some of the commonly used tools include tape measures, callipers, plumb bobs, and levels. The detailer also uses various software programs, such as Autocad, Tekla, and Revit, to create 2D and 3D models of steel structures.

[edit] Benefits of Structural Steel Detailing

Structural steel detailing offers many benefits, including improved accuracy and efficiency in construction, cost savings through material optimisation and reduction of rework, and enhanced safety through better visualisation and coordination. By using detailed drawings and models, structural steel detailing ensures that the final product meets the design specifications and is safe and efficient.

[edit] Key Elements of Structural Steel Detailing

The key elements of structural steel detailing include understanding the structural steel components and their characteristics, following detailing standards and codes and creating shop drawings and fabrication drawings. Steel Fabrication Shop Drawings provide detailed information on the fabrication and assembly of steel components, while fabrication drawings provide detailed information on the actual construction of the steel structure. These shop drawings are essential for the fabrication and assembly of steel components in the steel fabrication shop. They include detailed information on the size, shape, and location of steel components, as well as the materials and welding specifications. The fabrication drawings provide the necessary information for the construction of the steel structure on-site. They include detailed information on the connections between steel components, as well as the bolt and weld sizes and locations. Without accurate and detailed shop drawings and fabrication drawings, the fabrication and construction of the steel structure would be challenging and prone to errors.

[edit] Structural Steel Detailing Techniques

Structural steel detailing involves the use of various techniques, such as 2D and 3D modelling, BIM (Building Information Modelling), and CAD (Computer-Aided Design). 2D and 3D modelling allow the detailer to create detailed drawings and models of steel structures, while BIM enables the detailer to create a digital representation of the entire building. CAD allows the detailer to create precise and accurate drawings of steel components.

[edit] Structural Steel Detailing Challenges

Structural steel detailing comes with various challenges, such as ensuring the accuracy and completeness of drawings, dealing with complex geometries and designs, and meeting tight schedules and deadlines. The detailer must be able to work under pressure and be able to handle complex designs and geometries.

[edit] Importance of Communication and Collaboration

Effective communication and collaboration are essential in structural steel detailing. The detailer must work closely with structural engineers, architects, contractors, and fabricators to ensure that the final product meets the design specifications. The use of project management tools and software can help facilitate communication and collaboration throughout the project lifecycle.

[edit] Conclusion

Structural steel detailing is a critical process in the construction industry. It ensures that the final product is safe, accurate, and efficient. By using detailed drawings and models, structural steel detailing helps to reduce errors and rework, saving time and money. Effective communication and collaboration are essential in ensuring that the final product meets the design specifications. Advances in technology, such as BIM and CAD, will continue to drive innovation in the field of structural steel detailing.

[edit] Related articles on Designing Buildings

- As-built drawings and record drawings.

- Assembly drawing.

- Building information modelling.

- Component drawing.

- Computer aided design.

- Concept drawing.

- Detail drawing.

- Detail design.

- Demystifying design processes of architectural details.

- Detailed design report.

- Detailed services design.

- Detailed structural design.

- Installation drawings.

- Level of detail for BIM.

- Production information.

- Scale drawing.

- Section drawing.

- Shop drawings.

- Specification.

- Structural design.

- Technical drawing.

- Technical drawing pen sizes

- Value management.

- Whole life costs..

- Working drawings.

[edit] External Links

https://www.marsbim.com/services/structural-bim/steel-detailing.html

https://www.marsbim.com/services/structural-bim/steel-fabrication-shop-drawings.html

BIM Directory

[edit] Building Information Modelling (BIM)

[edit] Information Requirements

Employer's Information Requirements (EIR)

Organisational Information Requirements (OIR)

Asset Information Requirements (AIR)

[edit] Information Models

Project Information Model (PIM)

[edit] Collaborative Practices

Industry Foundation Classes (IFC)