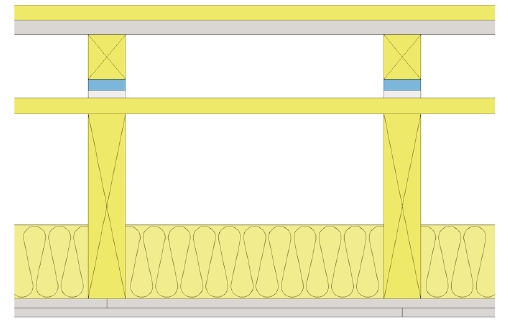

Resilient batten

The term ‘batten’ generally refers to a strip of timber (although it can also be steel or plastic) used in the construction of buildings. Battens are typically used as spacers to raise the surface of a material, or as a secondary framework onto which a surface may be fixed. Battens are used in the construction of roofs, walls, floors, ceilings and a number of other applications.

According to 'Housing and sound insulation, Improving existing attached dwellings and designing for conversions', published in 2006, the term 'resilient batten' refers to a timber batten with a resilient layer that can be placed under floor surfaces to reduce impact sound.

A resilient layer is a layer that isolates an element (such as screed or a floating floor) from another element (such as the base floor). Generally, the resilient layer is pre-bonded beneath the batten (although it is sometimes on top of the batten). It may be formed using foams, cellulose compounds or fibrous polyesters, and may use two or more densities or compounds of material, with different compositions giving different degrees of performance. For example, a 65–90mm system installed at 400 centres might give an airborne improvement of 8–12dB and an impact improvement of 12–18dB.

Resilient battens must be installed onto a flat surface and not directly laid onto joists or ribbed structures. Where there are timber joist floors, the resilient battens should be placed on a sub-deck board. It is important to ensure fixing tween the for flooring board to batten do not penetrate into the resilient layer.

[edit] Related articles on Designing Buildings Wiki

Featured articles and news

A forward thinking, inclusive global community of members.

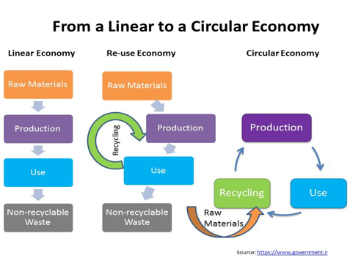

From engineered product life-spans, to their extension.

Circular economy in the built environment

A brief description from 2021. Where are we now?

Mental Health Awareness Week with ABS

Architects Benevolent Society programme of activity.

CLC publishes domestic retrofit competency framework

Roadmap of Skills for net zero.

May 13-19: Moving more for our mental health.

Understanding is key to conservation.

Open industry engagement survey seeks responses

Institutions and the importance of engagement.

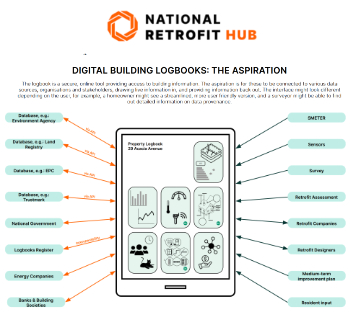

National Retrofit Hub unveils new guide

Digital Building Logbooks and Retrofit: An Introduction.

Enhancing construction site reporting efficiency

Through digitisation and the digital revolution.

Noise in the built environment

BSRIA guide TG 20/2021.

17,000 people suffer conditions as a result of exposure to excessive noise at work.

Turning down the noise: Auditory health

A pervasive risk with far-reaching consequences.

Getting the most out of heat pumps and heating

How heat pumps work and how they work best.

Cost-of-living crisis and home improvement plans

Starting on the right footing and top tips for projects.

Electrotechnical excellence, now open for entries.