Lifts for buildings

Contents |

[edit] Introduction

A lift (or elevator) is a form of vertical transportation between building floors, levels or decks, commonly used in offices, public buildings and other types of multi-storey building.

Lifts can be essential for providing vertical circulation, particularly in tall buildings, for wheelchair and other non-ambulant building users and for the vertical transportation of goods. Some lifts may also be used for firefighting and evacuation purposes.

[edit] History

Simple lifting platforms driven by people, animals or water are thought to have existed since the 3rd century BC. One of the earliest counter-weighted lifts was built for King Luis XV at Versailles.

Mechanically-driven lifts were first developed in the 19th century:

- In 1823 architects Burton and Hormer’s ‘ascending room’ gave tourists a panoramic view of London.

- In 1835 a belt-driven, counter-weighted, steam-driven lift was developed in England.

- In 1853 Elisha Graves Otis sold his first lifts incorporating an automatic safety brake.

- In 1857 the first steam-driven public lift was installed in New York.

- In 1870 the first hydraulic lift was installed in New York.

- In 1903 the first traction sheave counterweight lift was developed.

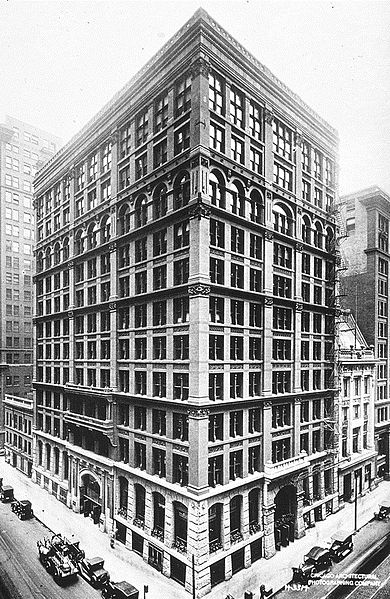

It was the availability of mechanical lifts in the middle of the nineteenth century that allowed the development of the first skyscrapers, most notably in Chicago in the 1880's.

Today, lift manufacturer Otis employs more than 60,000 people.

For more information, see A brief history of lifts over the years.

|

|

|

| Traditional lift | Home insurance building | Vandalised lift |

[edit] Definition

The Lifts Regulations 1997 define a ‘lift’ as:

'...a lifting appliance serving specific levels, having a car moving along rigid guides or a fixed course and inclined at an angle of more than 15 degrees to the horizontal, intended for the transport of:

- People.

- People and goods.

- Goods alone, if a person may enter without difficulty and fitted with controls inside the car or within reach of a person inside.'

Lifts can have several different types of operating mechanism, including:

- Hydraulic: An above ground or in-ground piston is used to raise or lower the lift under hydraulic pressure. Hydraulic lifts are generally only suitable in buildings of up to 8 storeys.

- Traction: Electrically-powered cable-operated lifts driven by steel ropes rolled over a pulley and balanced by a counterweight (sometimes a second lift moving in the opposite direction).

- Roped hydraulics, or hybrid lifts: Using both ropes and hydraulic power.

- Climbing lifts, which include their own means of propulsion, rather than being pulled or pushed from elsewhere.

Lifts that include glass panels, and are within a shaft that also includes glass panels, or are not within a shaft at all, sometimes on the outside of buildings may be referred to as ‘scenic lifts’.

Where a lift is within a glass enclosure, this might be described as a 'capsule lift'.

In very tall buildings, sky lobbies may be provided, which are are intermediate floors allowing passengers to transfer from an express lift that only stops at the sky lobby, to another lift that serves storeys above the lobby.

[edit] Evacuation lifts

Approved document B, Fire Safety, Volume 2, Buildings other than dwellinghouses (2019 edition) defines an evacuation lit as: 'a lift that may be used to evacuate

people in a fire.'

In general it is not appropriate to use lifts when there is a fire in the building because there is the danger of people being trapped in a lift that has become immobilised as a result of the fire. However, in some circumstances a lift may be provided as part of a management plan for evacuating people.

In such cases the lift installation may need to be appropriately sited and protected and may need to contain a number of safety features that are intended to ensure that the lift remains usable for evacuation purposes during the fire. Guidance on the design and use of evacuation lifts is given in BS 5588-8:1999.

Where a firefighting lift has been provided to satisfy requirement B5, this can be utilised as part of a management plan for evacuating disabled people. Any such plan should include a contingency for when the Fire and Rescue Service arrive.’

[edit] Firefighting lift

According to approved document B2, a firefighting lift is, ‘A lift designed to have additional protection, with controls that enable it to be used under the direct control of the fire and rescue service in fighting a fire... A firefighting lift is required if the building has a floor more than 18m above, or more than 10m below fire service vehicle access level.'

Firefighting lifts have very specific safety requirements and the presence of firefighting controls within a lift does not necessarily mean that it is a firefighting lift.

[edit] Regulations

Lift installation and manufacture must comply with the Lifts Regulations 1997, as amended by the UK Supply of Machinery (Safety) Regulations 2008. Lifts that travel faster than 0.15 metres per second, and their safety components which permanently serve buildings and constructions, must be safe for use and meet health and safety requirements. ‘Safety components’ include:

- Landing doors locking device.

- Devices to prevent the lift falling or rising unchecked.

- Devices to limit overspeed.

- Energy-accumulating buffers.

- Energy-dissipating buffers.

- Safety devices fitted to jacks of hydraulic power circuits used to prevent falls.

- Safety switches containing electronic components.

The Lifting Operations and Lifting Equipment Regulations (LOLER) provide guidance on lifts used by workers in workplaces. It requires lifts to be thoroughly examined by a competent person at least every six months or, in the case of goods-only lifts, every 12 months. Guidance for lift owners and other duty-holders is available in the HSE’s ‘Thorough examination and testing of lifts’.

LOLER may not apply where a lift is not used by people at work (e.g. in a shop used by customers). However, Section 3 of the Health and Safety at Work Act imposes general responsibilities for the safety of users.

BS EN 81-80 relates to the upgrading of existing lifts, to ensure they are safe for use. The aim is to meet the level of safety provided by a newly-installed lift.

[edit] Approved document M

The Equality Act 2010, requires that buildings must be accessible to people with disabilities. BS 8300 recommends that multi-storey buildings provide at least one accessible lift for wheelchair users.

General guidelines on the provision of lifts within buildings are outlined in Approved Document M – Access to and Use of Buildings. Section 3 within covers horizontal and vertical circulation in buildings other than dwellings.

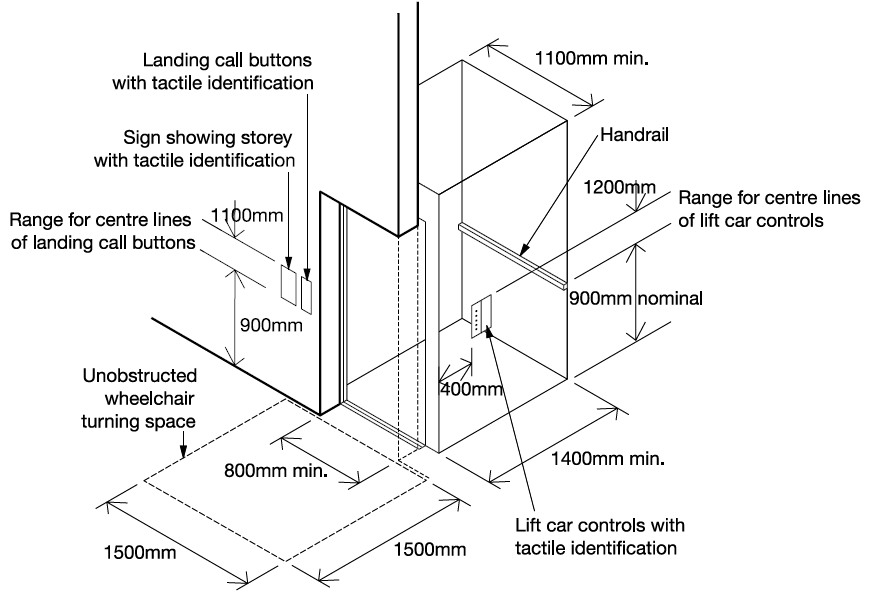

It suggests that ‘a passenger lift is the most suitable means of vertical access and should be provided wherever possible.’ Design requirements for lifts include; minimum space requirements, placement of controls, access to the lift car, a control panel that contrasts with decorations, visually distinctive landings and car doors, and the use of mirrors to provide a visual aid for reversing wheelchairs.

Further regulations require the inclusion of audiovisual warnings and announcements, tactile control buttons and other means of enabling access to users with certain disabilities.

Some of the key dimensions associated with lifts set out in approved document m are shown below.

[edit] British standards

There are a number of British Standards that apply to lifts:

- BS EN 81, Safety rules for construction and installation of lifts.

- BS 5588, Fire precautions in the design, construction and use of buildings.

- BS 7594, Code of practice for audio-frequency induction-loop systems (AFILS).

- BS 8300, Design of buildings and their approaches to meet the needs of disabled people – code of practice.

NB: For more information about lifts in office buildings, see Lifts for office buildings.

[edit] Research and development

A revolutionary rope-less 1:3 scale prototype is being tested in Spain using magnetic levitation by means of linear motors. This allows horizontal movement and multiple cars in a shaft working on a loop system. The potential is to provide a vertical people mover shuttle service (not unlike the horizontal equivalent of Circle line underground transport service in London).

It has the attraction of increasing shaft capacity by 50% leading to increased usable area in high rise buildings by some 25%. Waiting time is reduced however there is no available information at this time on travel times during peak hours.

In May 2016, the Mitsubishi Electric Corporation announced that it would be installing its new elevator technology to the Shanghai Tower. Their elevators had achieved a speed of 1,230 m/min, or 20.5 m/sec, the fastest ever recorded.

For more information, see Shanghai Tower.

[edit] Related articles on Designing Buildings Wiki

- A brief history of lifts over the years.

- Braille signage and accessibility.

- Considerations When Installing a Residential Lift.

- Counterweights.

- Disabled access lifts.

- Firefighting lift.

- Hoists.

- Home lifts.

- Lifting device.

- Lifting Operations and Lifting Equipment Regulations (LOLER).

- Lifting platform.

- Lift motor room.

- Lift Standards: EN 81-20 and EN 81-50.

- Lifts and Their Special Operating Modes.

- Lifts for office buildings.

- Liftway.

- Low pit lifts.

- Pulley.

- The hidden mechanics of lift routing.

- The importance of service lifts.

- The science of lifts.

- The world's fastest lifts.

- Through-floor lifts.

- Top factors to consider when planning to install a lift.

- Types of lift doors.

- Wheelchair platform stairlifts.

- Work at height.

[edit] External references

- CIBSE Lifts Group. Promotes technical standards, training and education for vertical transportation and includes a lifts microsite.

- Dept. for Business, Innovation & Skills – Lift manufacture and installation: responsibilities and regulations,

- Lifting Operations and Lifting Equipment Regulations (LOLER),

- Lifts Regulations 1997

Featured articles and news

Introducing or next Guest Editor Arun Baybars

Practising architect and design panel review member.

Quick summary by size, shape, test, material, use or bonding.

Types of rapidly renewable content

From forestry to agricultural crops and their by-products.

Terraced houses and the public realm

The discernible difference between the public realm of detached housing and of terraced housing.

Put digitalisation and sustainability at the core of curricula

Project management educators are urged.

Looking back at the influence of climate events

From a designer and writer: 'There are limits to growth but no limits to development'.

Terms, histories, theories and practice.

Biophilic design and natural light

Letting in the light and natural elements into spaces.

APM Programme Management Conference 2024

Strategies for Success.

Residential takes the reins as contract awards even out

Contracts down, but remain above the last quarter of 2023.

Celebrating Eid and the largest mud-brick building.

Barry Kingscote claims prestigious CIOB CMYA Award.

The British Mosque: an architectural and social history

The story of some 1,500 mosques or more in Britain.

Heat pump refrigerants, efficiencies and impacts

R12 to R1270 what are the differences?

Global heat pump market in 2023

Challenging times with positive but modest outlook.

Beyond the infrastructure pipeline

Opportunities and chokepoints.

Comments

Very good article, thanks. I'm interesting in list architecture, lift configurator and lift design so would like to hear more nice good and informative articles like thise.